TBM cutter head with cavitation jet assisted rock breaking and rock breaking method

A technology of cavitation and cutter head, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems that the tunnel construction period cannot be well guaranteed, the cost of tunnel excavation increases, and the excavation speed decreases, so as to improve the performance of rock breaking Efficiency, optimum rock breaking, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

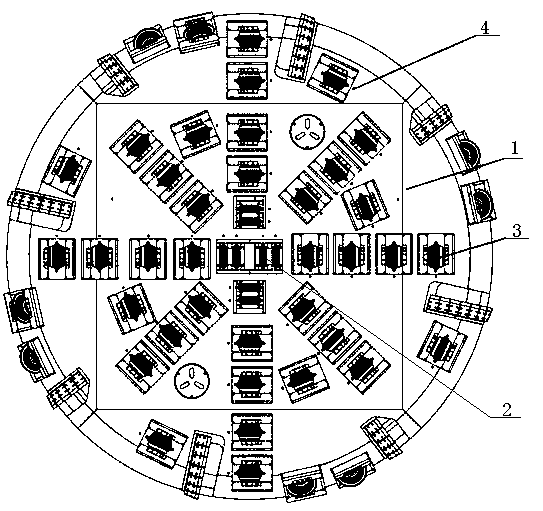

[0033] Example 3, such as Figure 4 Shown, a kind of rock-breaking method of the TBM cutter head of cavitation jet assisting rock-breaking, specifically as follows:

[0034] S1: When the TBM cutter head is rotating, the center hob 2 and the front hob 3 rotate to form multiple concentric cutting tracks, and the water jet is delivered to the cutter head area through the rotary joint, and flows into the cavitation jet nozzle through the high-pressure water pipe;

[0035] S2: The cavitation jet nozzle located on the front side of the movement direction on the same concentric cutting track ejects cavitation jet to erode the hard rock surface and reduce various properties of the rock;

[0036] S3: After the cavitation jet erodes the hard rock surface to a certain extent, the central hob 2 and the front hob 3 carry out the hob breaking of the rock, forming the main damage to the rock mass;

[0037] S4: After the rock is broken by the hob, the cavitation jet nozzle located on the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com