Water jet and corrosive liquid lower cutter ring wear test device and test method

A wear test, water jet technology, applied in the direction of measuring devices, testing wear resistance, using mechanical devices, etc., can solve the complex disassembly and installation process of the hob and its accessories, the heavy cutting load of the hob, and the impossibility of hob cutting wear test etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

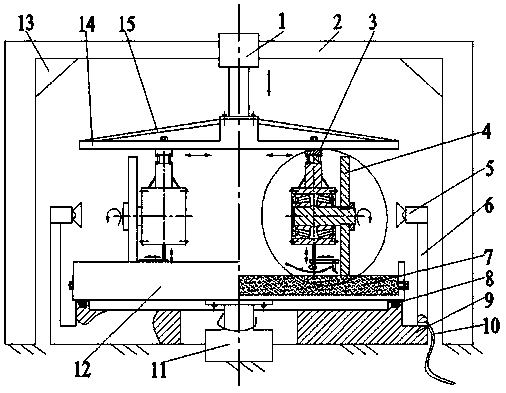

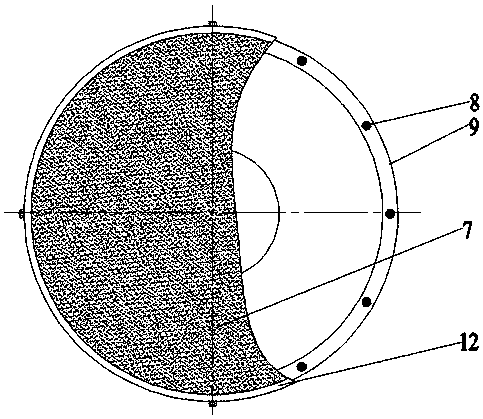

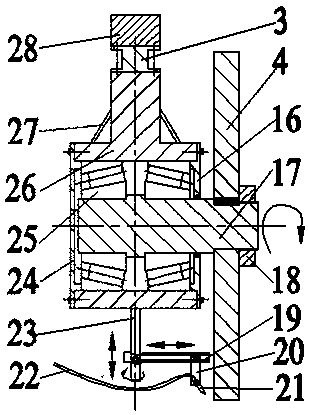

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0061] as attached figure 1 , figure 2 and image 3 As shown, the hob cutter ring wear test device under water jet assisted and corrosive liquid conditions consists of a telescopic oil cylinder 1, a three-dimensional frame 2, a three-way force sensor 3, a reduced size cutter ring 4, an infrared thermometer 5, and a support base Outer ring 6, extremely hard rock sample 7, wear-resistant roller 8, support base chassis 9, liquid conduit 10, hydraulic motor 11, bin box 12, frame support rib 13, beam 14, beam support rib 15, bearing Right end cover 16, cutter shaft 17, fastening nut 18, horizontal nozzle guide rail 19, nozzle bracket 20, nozzle 21, water jet conduit 22, vertical nozzle guide rail 23, bearing left end cover 24, bearing 25, knife holder 26, knife holder Support rib 27, connecting plate 28 forms.

[0062]The telescopic oil cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com