Excavator bucket tooth

A technology of excavator bucket teeth and bucket teeth, which is applied in the field of machinery, can solve problems such as hindering the installation of new bucket teeth, cumbersome installation operations, and difficult removal, and achieve the effects of simple and convenient installation and disassembly, improved utilization rate, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

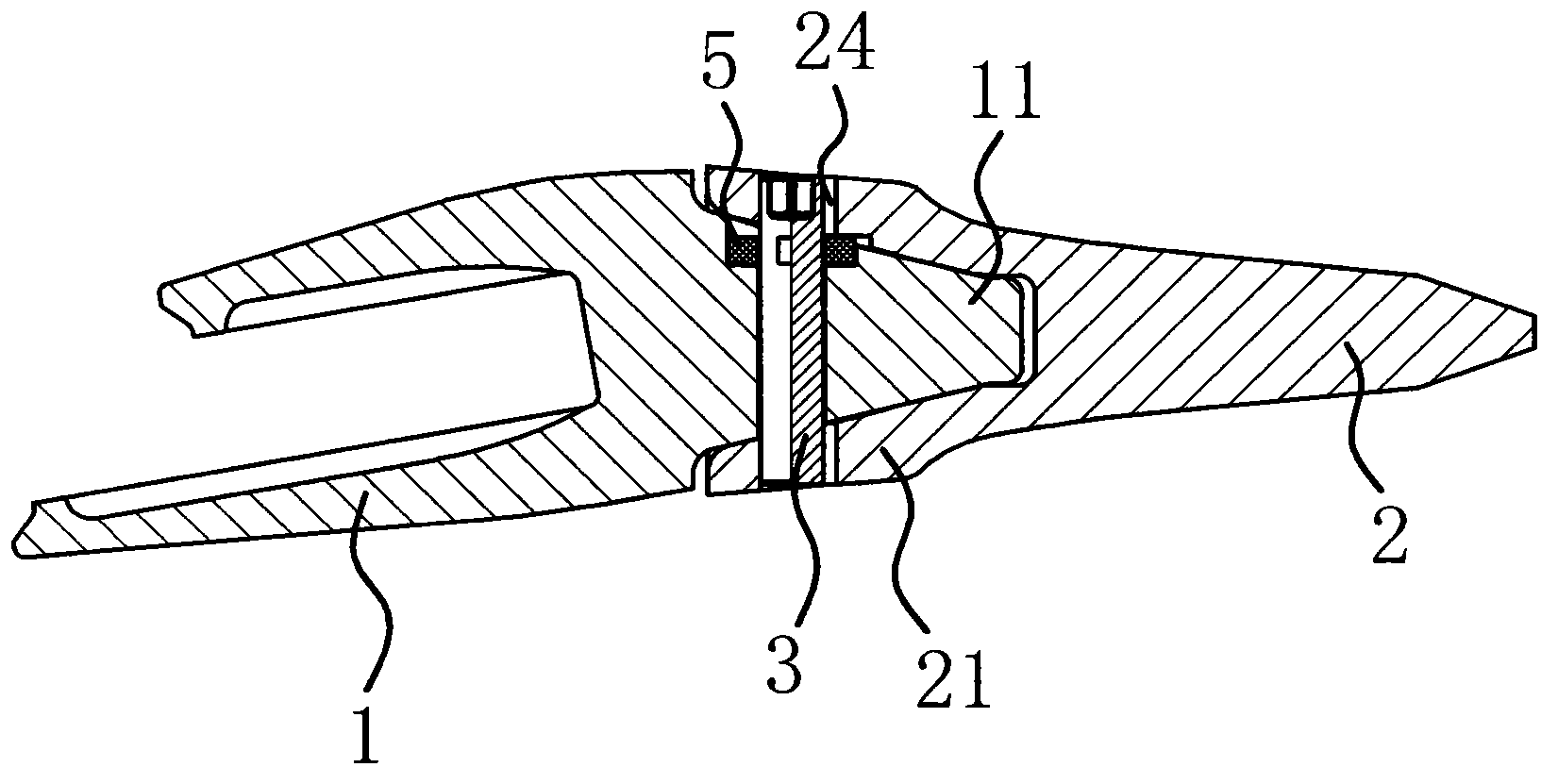

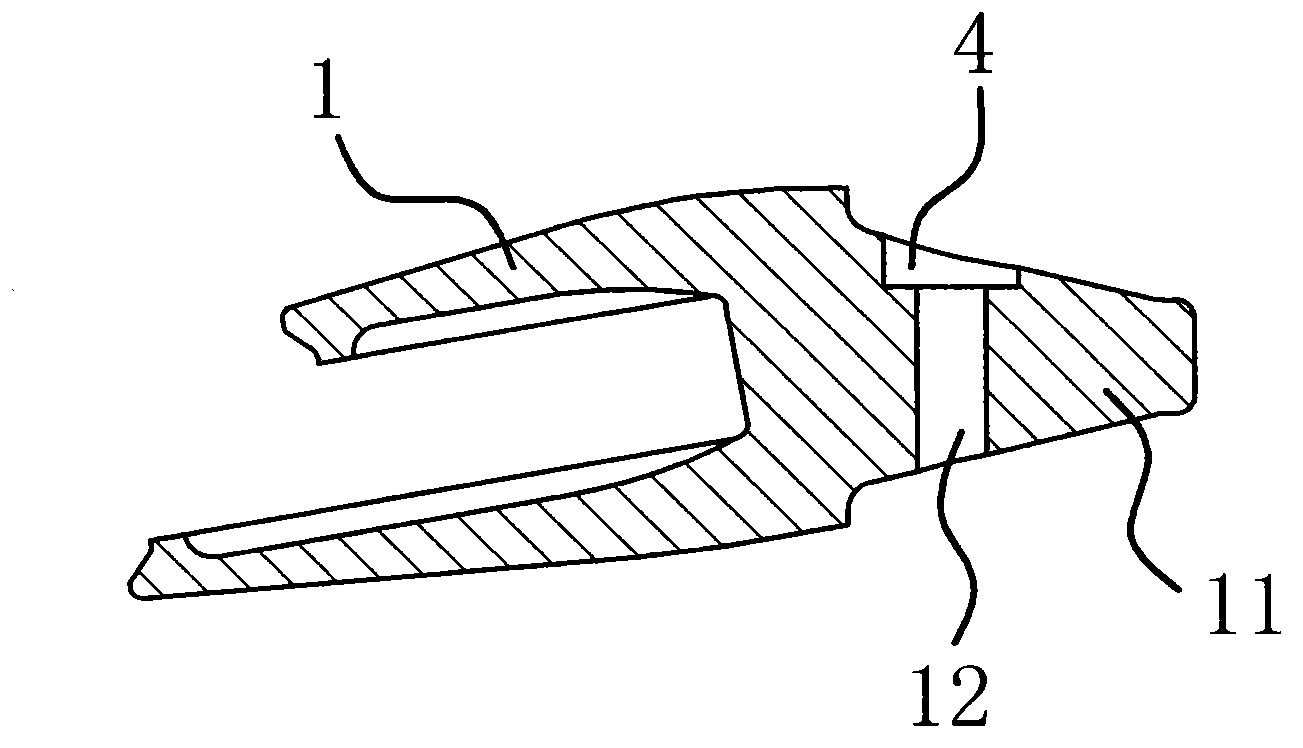

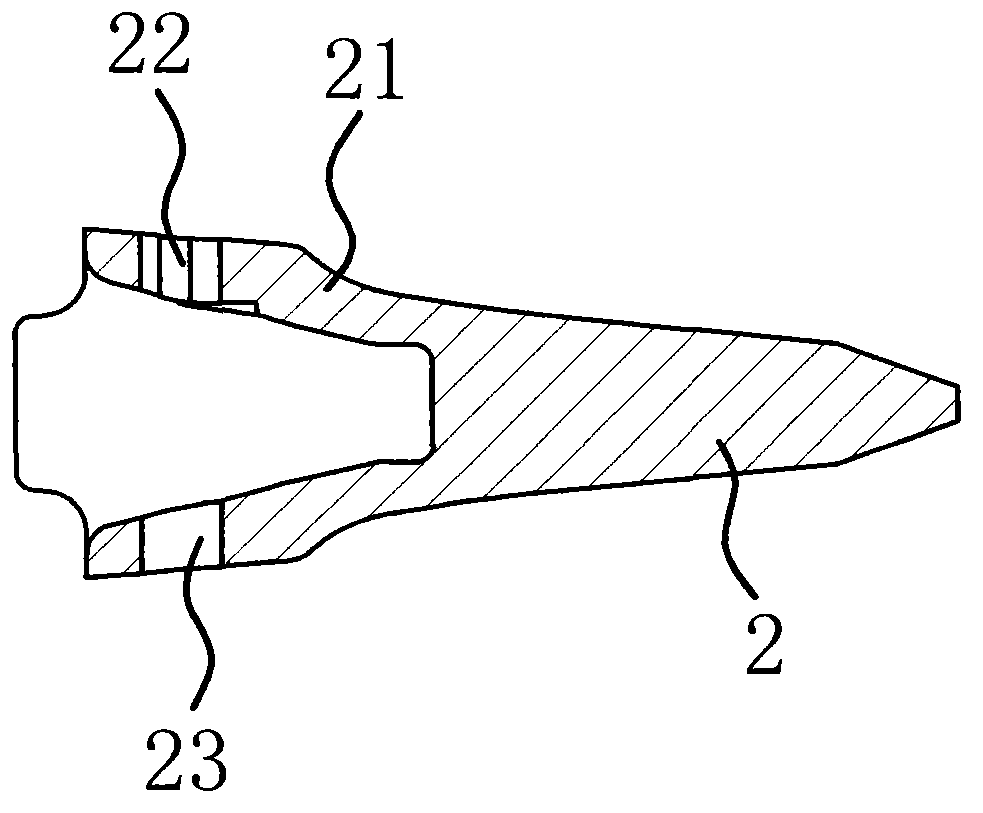

[0036] Such as figure 1 As shown, the bucket tooth 2 of the excavator includes a tooth holder 1 with a mounting portion 11 and a bucket tooth 2 with a connecting portion 21 , and the mounting portion 11 is inserted into the connecting portion 21 . Such as figure 2 As shown, the mounting part 11 has a mounting hole 12 arranged through it, as image 3 As shown, the connecting portion 21 has a second installation hole 22 and a third installation hole 23 arranged through it, and the second installation hole 22 and the third installation hole 23 are arranged coaxially. In this embodiment, the second mounting hole 22, the first mounting hole 12 and the third mounting hole 23 form a through pin hole, such as figure 1 As shown, a pin 3 is pierced in the pin hole. Specifically, such as Figure 4 and Figure 5 As shown, the outer wall of the pin 3 has a radially protruding positioning portion 31, such as figure 1 As shown, the inner side wall of the second mounting hole 22 has a ...

Embodiment 2

[0047] The principle of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 7 and Figure 8 As shown, the first mounting hole 12 is horizontally penetrated on the mounting part 11, such as Figure 9 As shown, the second mounting hole 22 and the third mounting hole 23 are horizontally penetrated on the connecting part 21, and as Figure 9 As shown, the positioning groove 4 is provided on the connecting portion 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com