Femtosecond laser machining system for nano-twin diamond tool, and machining method based on system

A technology of femtosecond laser processing and diamond tools, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problem of inability to prepare nano-twinned diamond tools, achieve the goal of improving strong ablation damage and improving processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

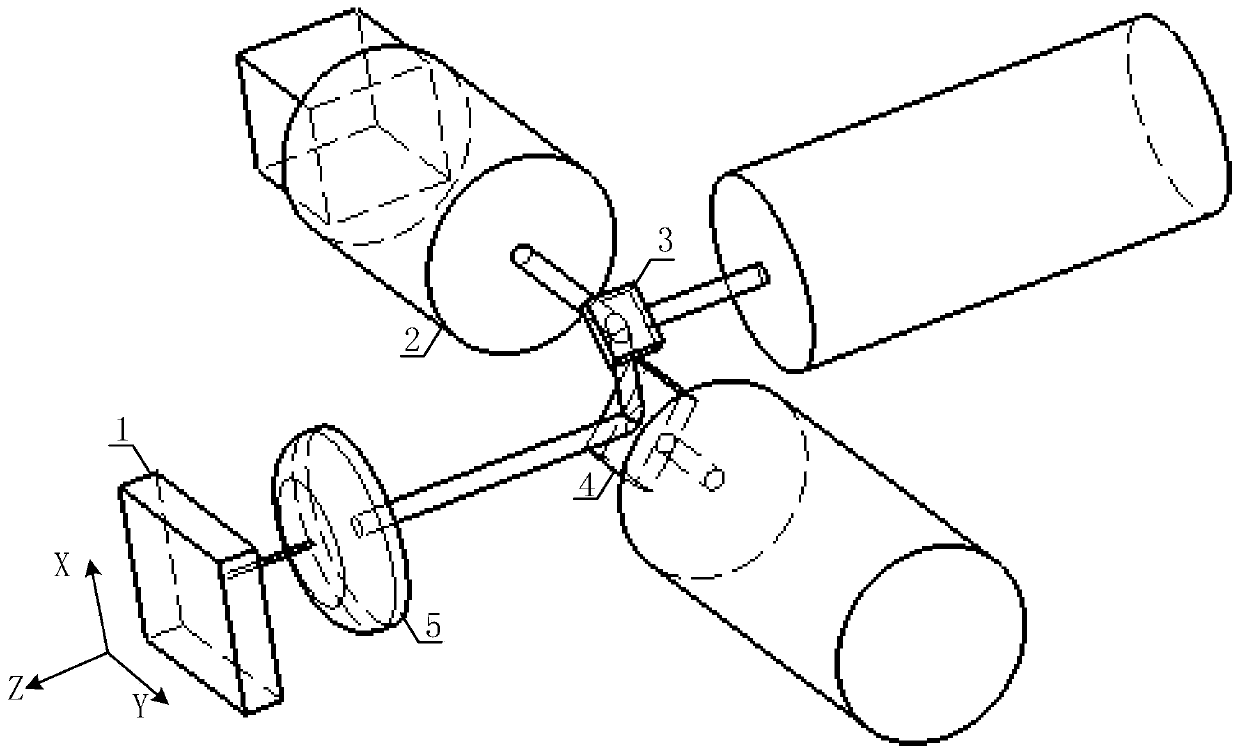

[0026] Specific implementation mode one: refer to figure 1 This embodiment is specifically described. The femtosecond laser processing system for nano-twinned diamond tools described in this embodiment includes: a light source 2, a vibrating mirror system, a focusing lens 5, and a displacement table 1. The vibrating mirror system includes a first vibration reflection Mirror 3, the first vibrating motor, the second vibrating mirror 4 and the second driving motor;

[0027] The outgoing light of the light source 2 is incident on the first vibrating mirror 3 through the reflection system, the reflected light of the first vibrating mirror 3 is incident on the second vibrating mirror 4, and the reflected light of the second vibrating mirror 4 is focused to the On the workpiece on the surface of stage 1,

[0028] The first vibrating motor is used to drive the first vibrating mirror 3 to move, so that the beam focused by the focusing lens 5 can move along the Y direction,

[0029] T...

specific Embodiment approach 2

[0035] Specific embodiment two: this embodiment is based on the processing method of the femtosecond laser processing system for the nano-twinned diamond tool described in the specific embodiment one, in this embodiment,

[0036] The light source 2 is turned on, so that the laser beam focused by the focusing lens 5 is incident on the surface to be processed of the workpiece.

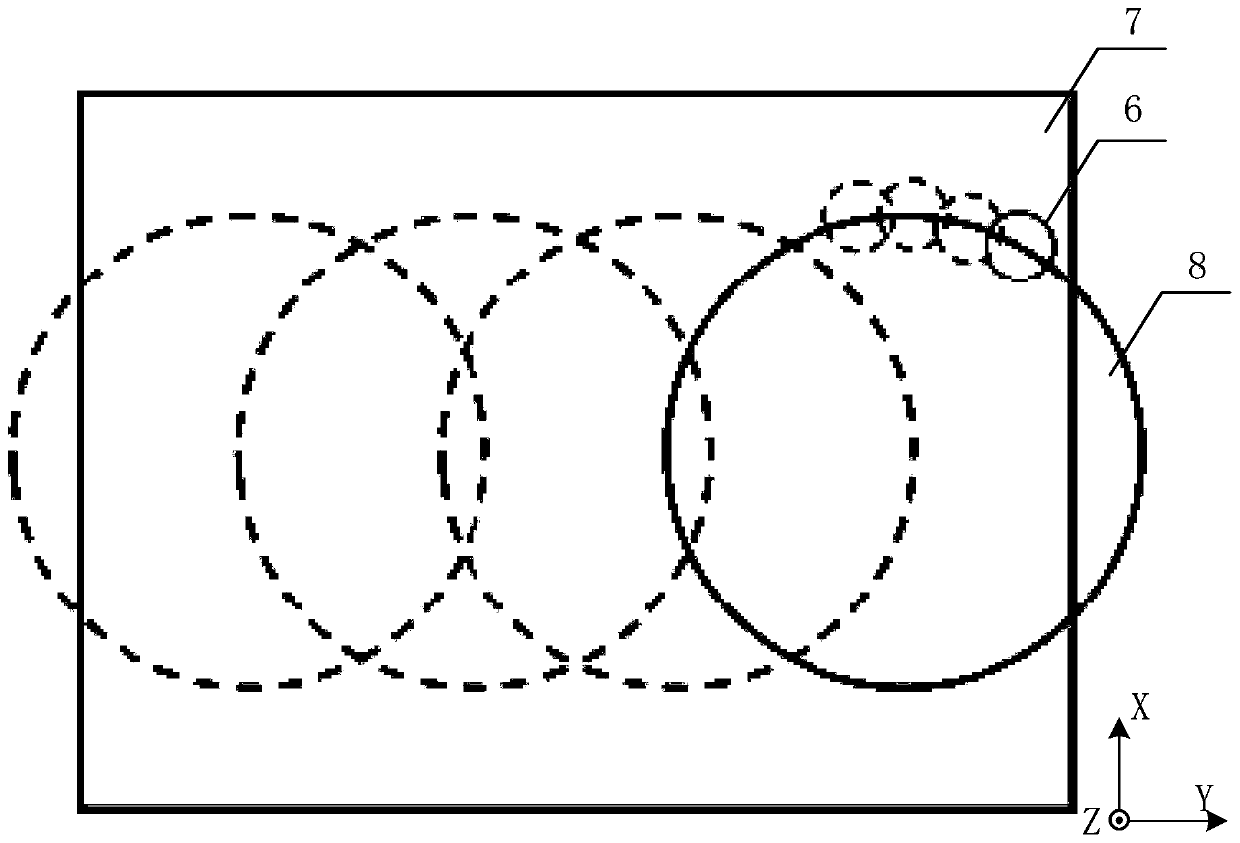

[0037] Start the first vibration motor and the second drive motor, respectively drive the first vibration mirror 3 to move along the Y direction, and the second vibration mirror 4 to move along the X direction, so that the laser light after the focusing lens 5 is focused moves along a circular trajectory; In a complete circular trajectory, the number of similar blades n, laser pulse frequency f l and vibration frequency f of the galvanometer system g satisfy the following formula:

[0038] n=f l / f g .

[0039] The displacement stage 1 is driven to move along the Y direction to complete the machinin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com