Preparation method for food-grade small-grain-size nano-silver sol

A nano silver sol, small particle size technology, applied in nanotechnology and other directions, can solve the problems of difficult to eliminate harmful anions of nano silver glue, large particle size of nano silver glue, poor bactericidal performance, etc., to achieve high dispersion performance, bactericidal ability The effect of strong and stable dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] First, silver nitrate and water are mixed according to the requirement that the silver content in the solution is 20pm, sodium octadecyl sulfate or sodium stearate is added to the silver nitrate solution, and the mixed solution is stirred for 10 minutes, then, the obtained The mixed solution is subjected to an aging reaction, specifically, after irradiating with a light source containing ultraviolet rays for 30 minutes, a nano-silver sol with a particle size of 2 nanometers can be obtained.

Embodiment 2

[0019] First, silver nitrate and water are mixed according to the requirement that the silver content in the solution is 100pm, sodium octadecyl sulfate or sodium stearate is added to the silver nitrate solution, and di-octyl succinate sulfonic acid is added to the solution Sodium (AOT) replaces the harmful negative ions in the solution, and stirs the mixed solution for 15 minutes, then, the obtained mixed solution is subjected to an aging reaction, specifically, the particle size can be obtained after irradiating with a light source containing ultraviolet rays for 2 hours Nano silver sol with a small particle size of 2 nanometers.

Embodiment 3

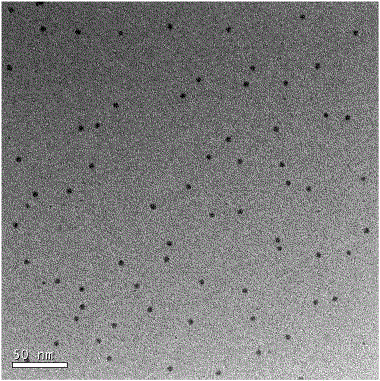

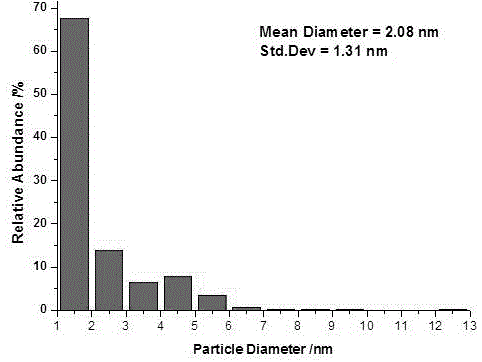

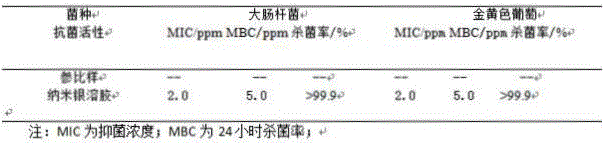

[0021] First, mix silver nitrate and water according to the requirement that the silver content in the solution is 10000pm, add sodium octadecyl sulfate or sodium stearate into the silver nitrate solution, and then add di-octyl succinate sulfonic acid into the solution Sodium (AOT) replaces the harmful negative ions in the solution, and stirs the mixed solution for 20 minutes. Then, the obtained mixed solution is subjected to an aging reaction. Specifically, the particle size can be obtained after irradiating with a light source containing ultraviolet light for 24 hours. Be 2 nanometers small diameter nano-silver sol, make the TEM result of nano-silver as follows figure 1 As shown, the particle size distribution is as figure 2 As shown, the antibacterial test results are as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com