Preparation process of porous ceramic adsorption material high in adhesion rate and easy to desorb

A technology of porous ceramics and adsorption materials, applied in the field of ceramic materials, can solve problems such as difficult cleaning, reduced washing force, and difficult cleaning of pores, and achieve the effects of enhancing filtration and adsorption efficiency, increasing adsorption rate, and enhancing filtration and adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

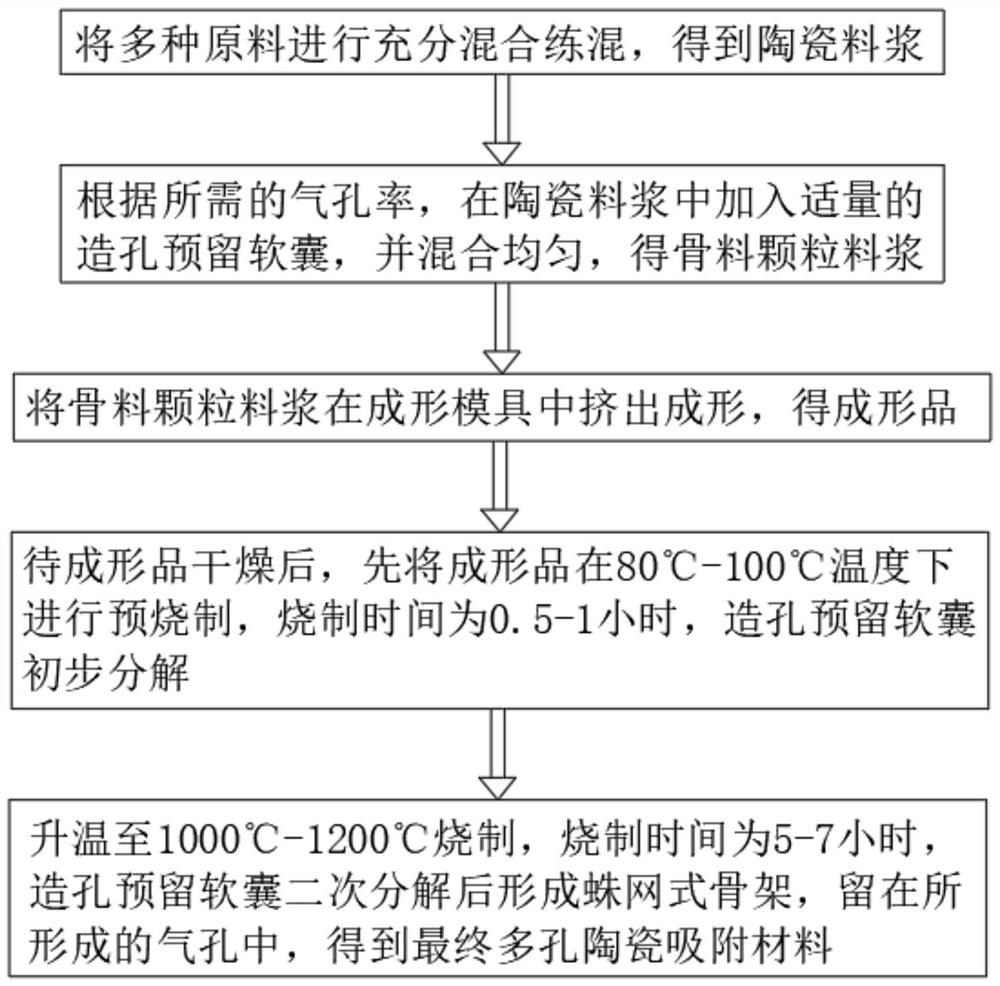

[0049] see figure 1 , a high adhesion rate and easy desorption porous ceramic adsorption material preparation process, comprising the following steps:

[0050] S1. Fully mixing and kneading various raw materials to obtain ceramic slurry;

[0051] S2. According to the required porosity, add an appropriate amount of pore-forming soft capsules into the ceramic slurry, and mix evenly to obtain aggregate particle slurry;

[0052] S3, extruding the aggregate particle slurry in a forming mold to obtain a formed product;

[0053] S4. After the molded product is dried, pre-fire the molded product at a temperature of 90°C for 0.5 hours, and preliminarily decompose the soft capsule reserved for pore making;

[0054] S5. Heat up to 1200°C and fire for 6 hours. The pore-forming reserved soft capsules are decomposed twice to form a spider web-like skeleton, which remains in the formed pores to obtain the final porous ceramic adsorption material.

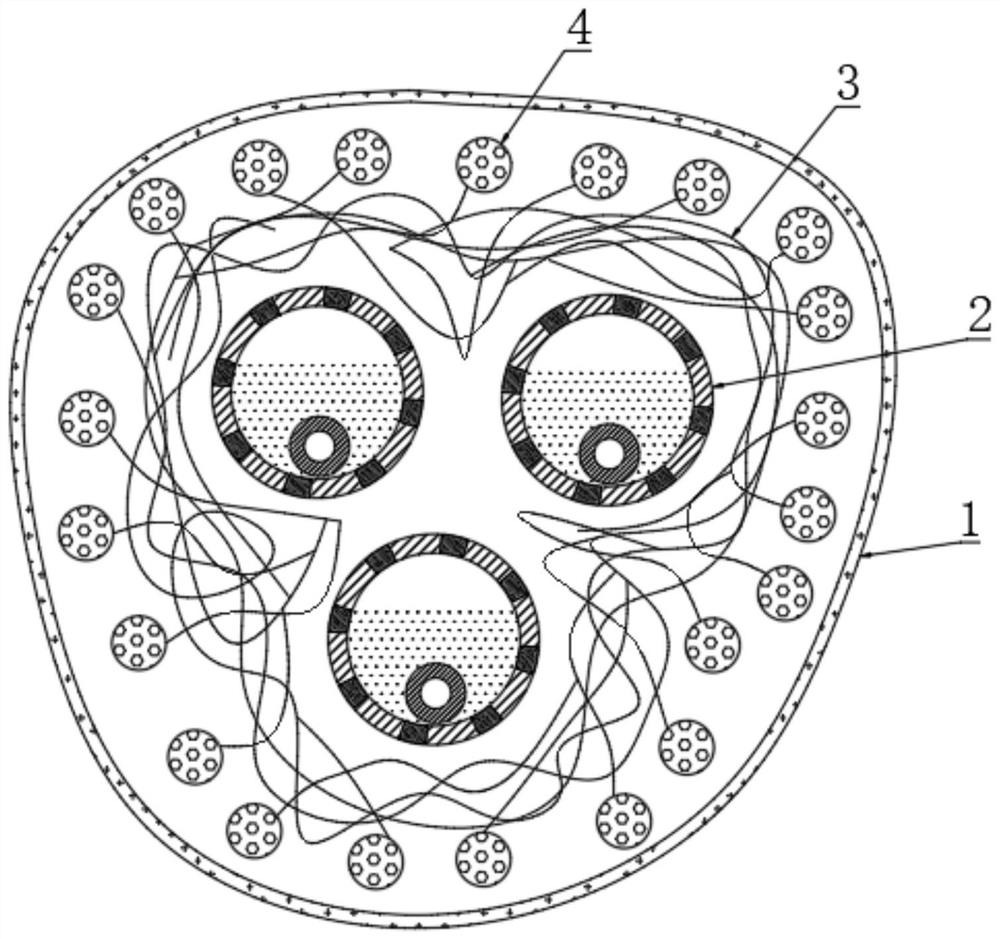

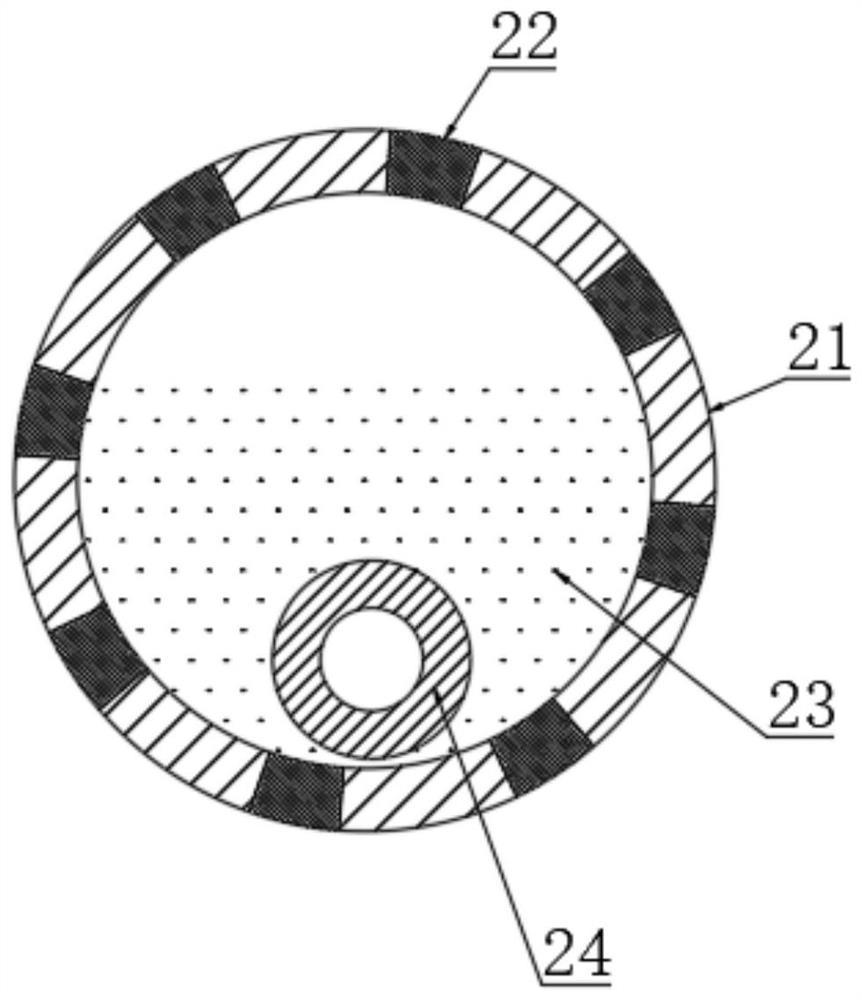

[0055] see figure 2 The pore-forming s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com