Method for preparing a substrate by implantation and irradiation

一种衬底、注入粒子的技术,应用在半导体/固态器件制造、电气元件、电路等方向,能够解决劣化、不再具有最佳晶体矩阵等问题,达到减少光预算的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

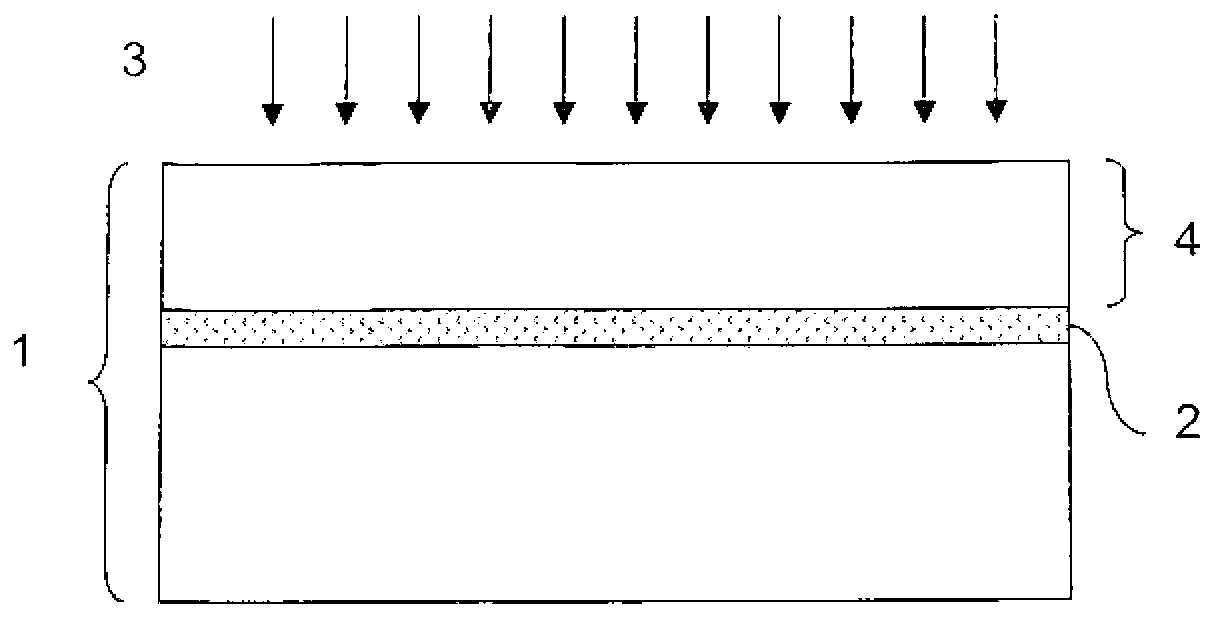

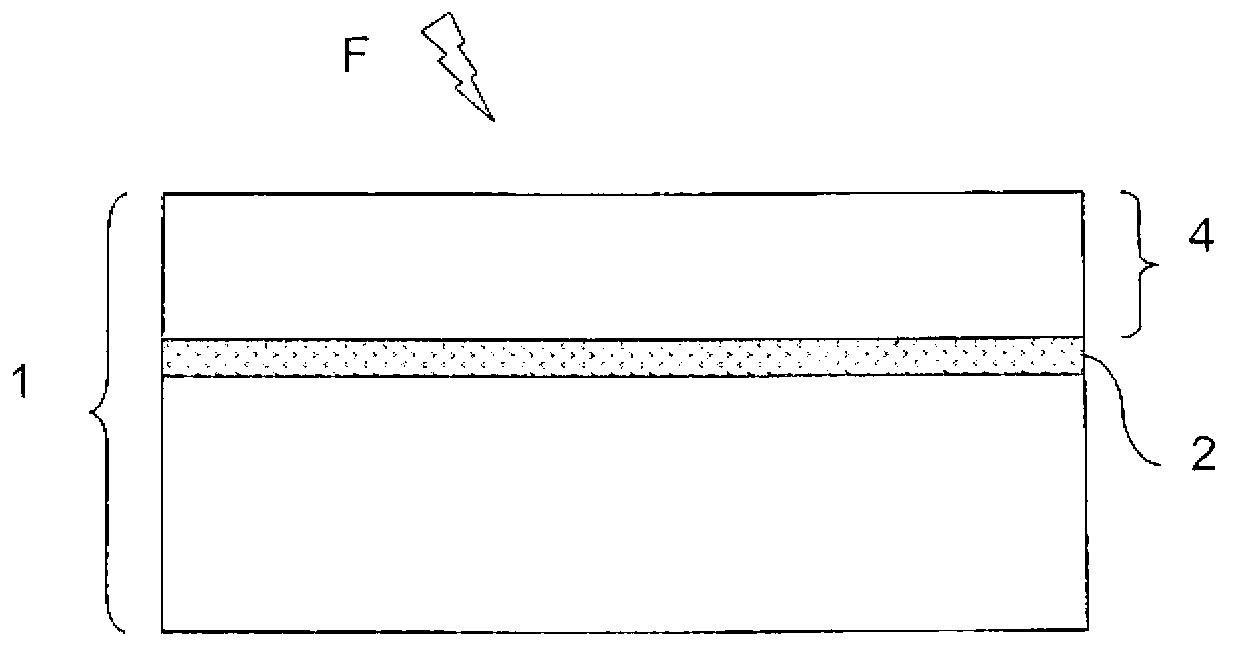

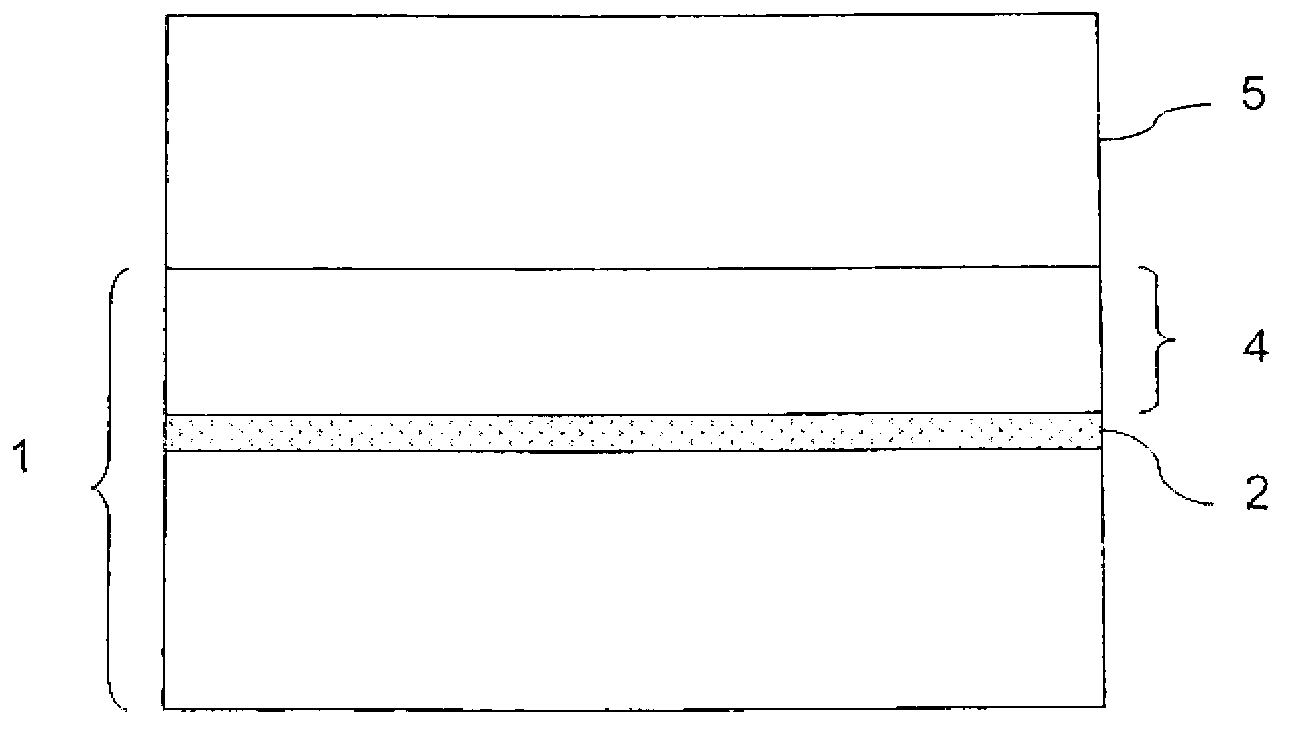

[0046] The present invention is applicable to any substrate made of crystalline or amorphous composite materials, the optical absorption properties of the composite materials (especially the optical absorption coefficient in the specified frequency range, or the imaginary part of the refractive index) can pass through the particles Inject and change in a local area. The composite material must also be able to decompose in the area under the influence of the energy input of the light flux in and near the area.

[0047] "Composite material" refers to a material composed of at least two elements.

[0048] "Decomposition" refers to a change in the basic structure of a material. Depending on the material, the change may consist of phase separation, generation of new phases, generation of inclusions, and the like.

[0049] Composite materials are materials composed of at least two kinds of atoms. Among the composite materials, III-V compound semiconductors, especially nitrides (ie, the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption coefficient | aaaaa | aaaaa |

| diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com