Two-level vibration isolation hydraulic mount

A hydraulic suspension and vibration isolation technology, which is applied in the field of auto parts, can solve the problems affecting the ride comfort in the car, and achieve the effects of ensuring strength, reducing processing difficulty and cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

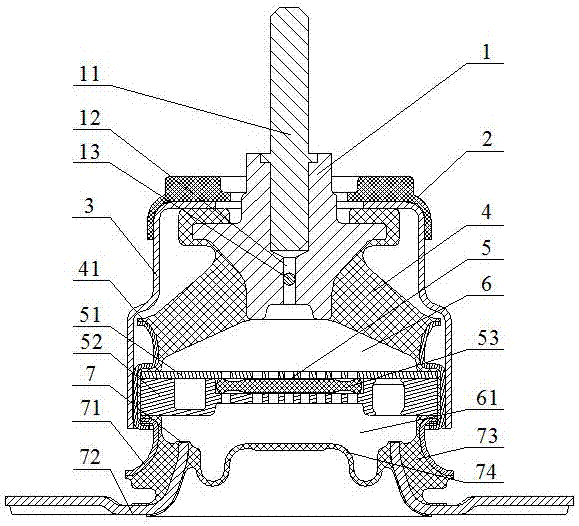

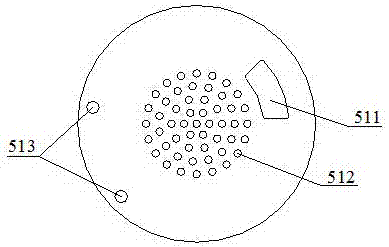

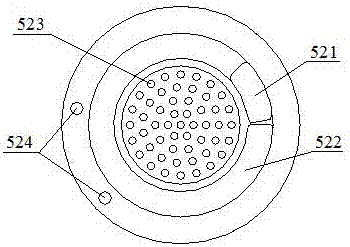

[0021] Such as figure 1 As shown, a two-stage vibration-isolation hydraulic mount includes an inner core 1, a limit cover 3, an anti-collision cover 2, a flow channel assembly 5 and connecting bolts 11, and a rubber main spring is provided at the lower part of the inner core 1 4. The outer wall of the lower part of the rubber main spring 4 is provided with a main spring outer frame 41, the lower part of the limit cover 3 is press-fitted on the outer wall of the main spring outer frame 41, and the top of the limit cover 3 is press-fitted on the rubber The top of the main spring 4 is separated from the shoulder of the inner core 1 by a certain limit distance, the anti-collision cover 2 is covered on the top of the limit cover 3, and the bottom of the rubber main spring 4 is provided with a vibration isolation seat 7, A closed liquid chamber is formed between the vibration isolation seat 7 and the rubber main spring 4, and the liquid chamber is divided into an upper liquid chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com