Vibration energy transmission-based vibration reduction design method for hub motor driven vehicle

A technology of vibration energy and hub motors, which is applied in mechanical equipment, combustion engines, internal combustion piston engines, etc., can solve the problems that have not been involved, and the research work of hub motor-driven vehicles is limited, so as to reduce vibration energy and improve ride comfort. Riding comfort and the effect of improving the overall performance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples, but the embodiments of the present invention are not limited thereto.

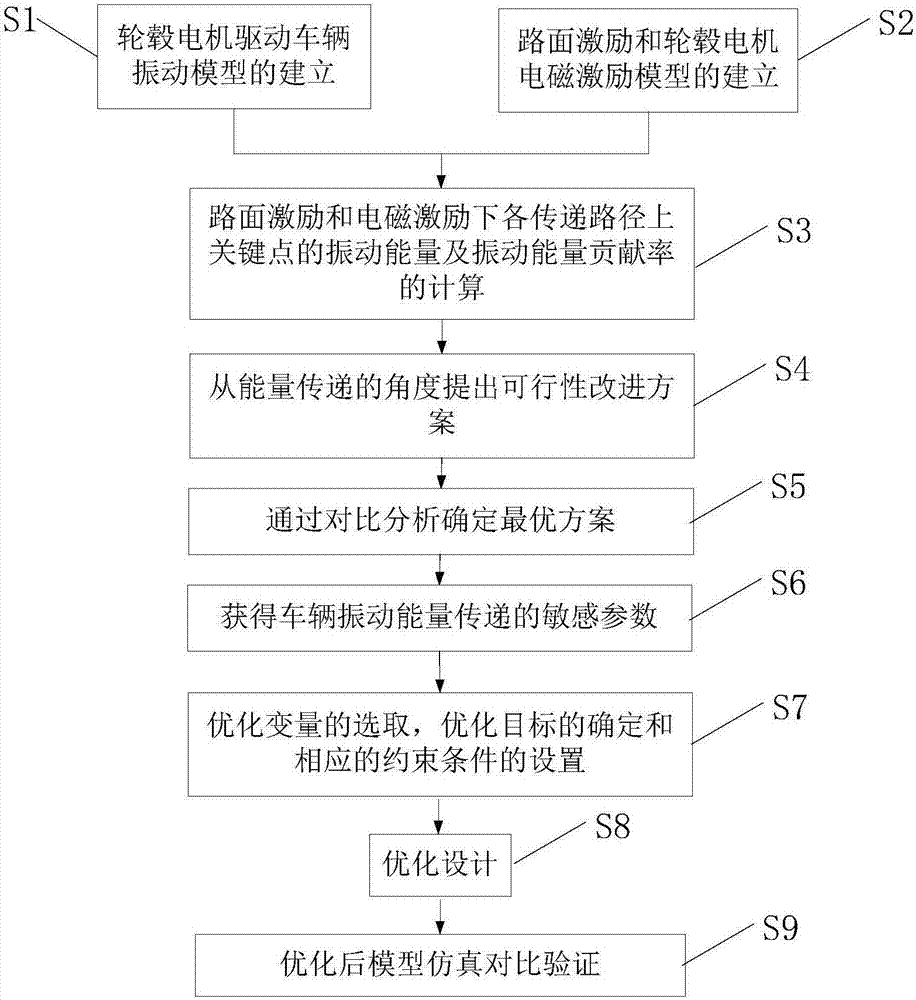

[0011] Such as figure 1 As shown in the flow chart, a vibration reduction design method for an in-wheel motor-driven vehicle proposed by the present invention, the steps include: S1: establishment of a vibration model of an in-wheel motor-driven vehicle; S2: establishment of a road excitation and in-wheel motor excitation model; S3: calculation Analyze the vibration energy and vibration energy contribution rate of each key point of the vehicle vibration model under road excitation and electromagnetic excitation; S4: Propose a feasible improvement plan from the perspective of vibration energy transfer; S5: Determine the optimal plan through comparative analysis; S6: Obtain Sensitive parameters of vehicle vibration energy transfer; S7: selection of optimization var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com