Shock absorption foundation structure of device and construction method of shock absorption foundation structure

A technology of basic structure and construction method, applied in the field of shock absorption foundation, can solve the problems of short service life, complicated installation, mechanical equipment damage, etc., and achieve the effect of reducing construction cost, improving equipment accuracy, and reducing vibration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

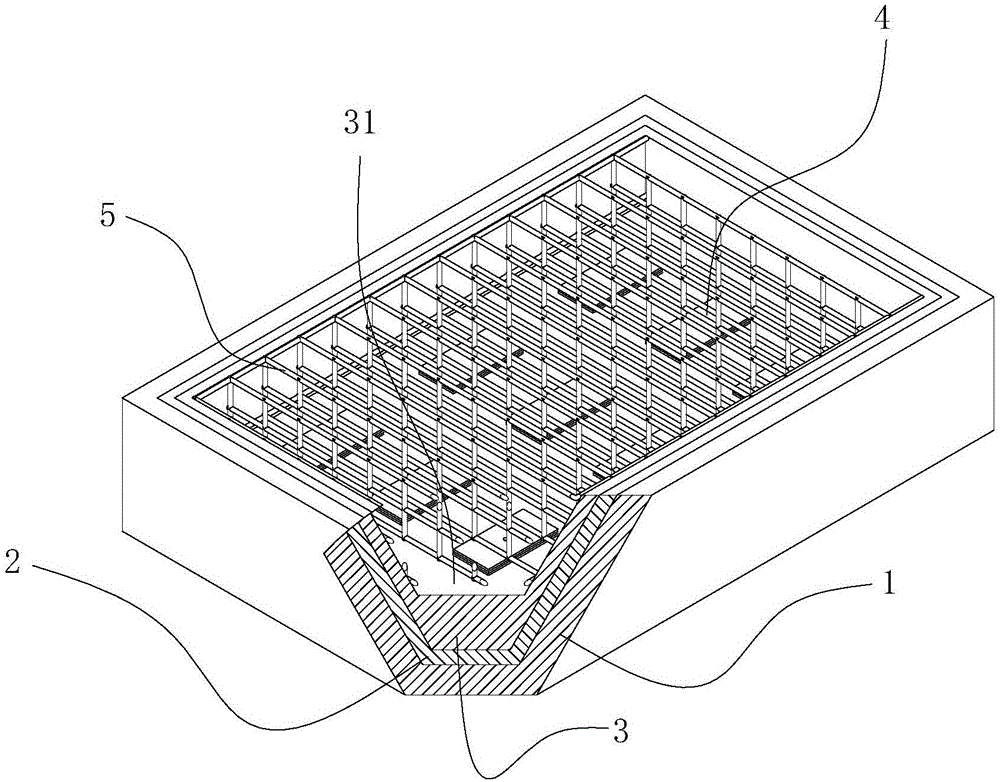

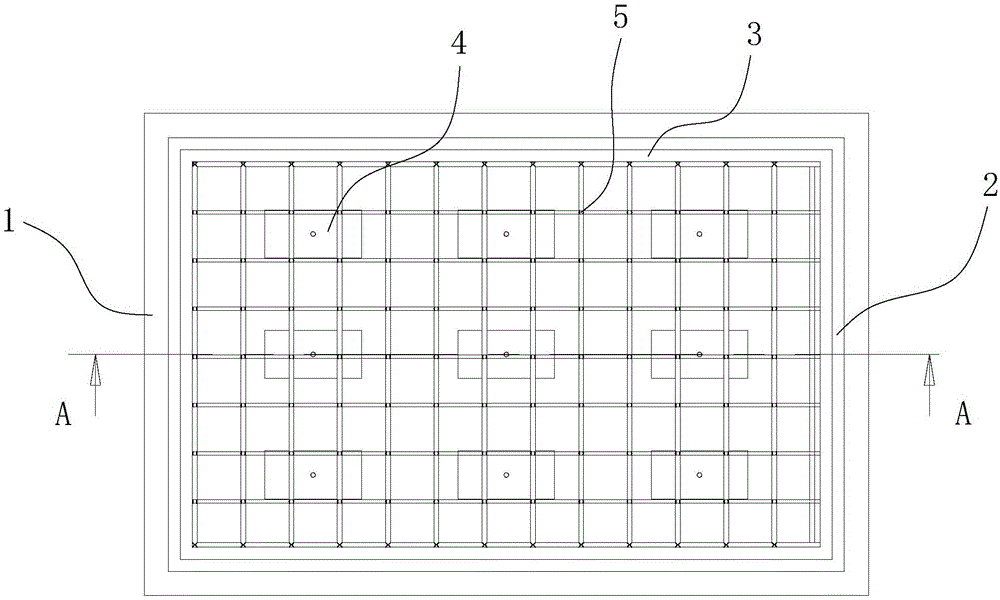

[0037] Such as Figure 1-Figure 5 As shown, the shock-absorbing infrastructure of the equipment of the present invention includes a base layer 1, a filling layer 3, a shock absorber 4, and a secondary foundation;

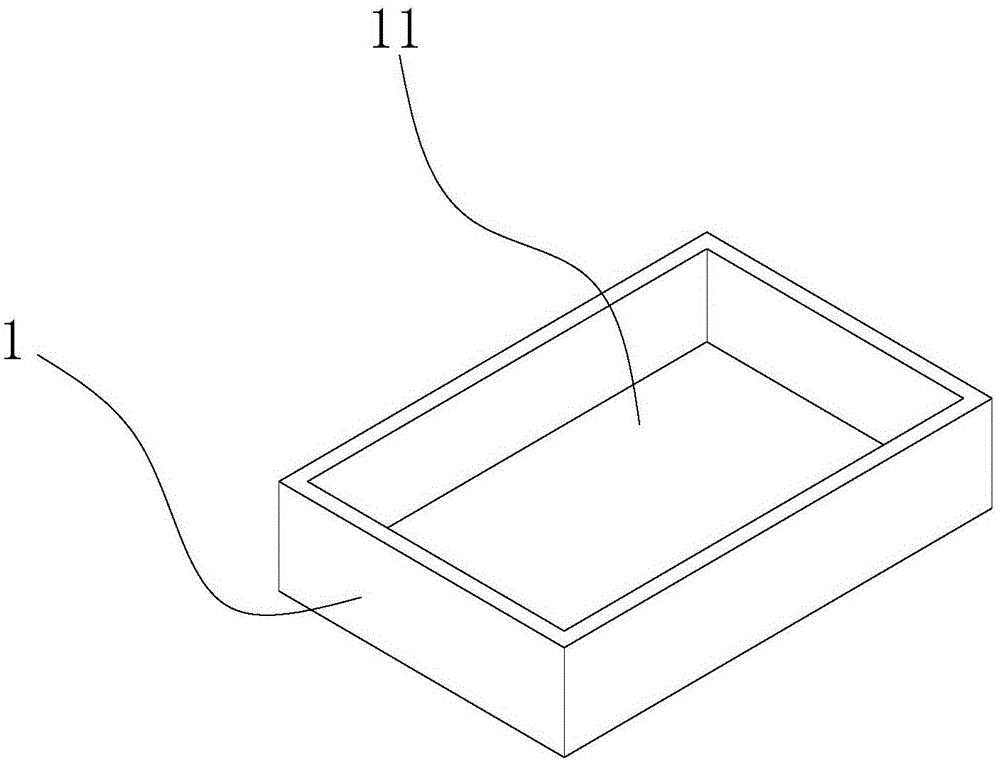

[0038] The base layer 1 has a shock-absorbing groove 11; the shock absorber 4 has a mounting surface 425 and a shock-absorbing surface 415; the mounting surface 425 of the shock absorber 4 is installed on the foundation base plate that the shock-absorbing groove 11 has; the The filling layer 3 is arranged on the inner wall and the foundation floor of the shock absorbing groove 11, and the filling height of the filling layer 3 above the foundation floor of the shock absorbing groove 11 is lower than the shock absorbing surface 415 of the shock absorber 4 and does not exceed 30 mm. The filling layer 3 forms the installation groove 31 ; the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com