Ventilated and resilient shoe apparatus and system

a shoe apparatus and resilient technology, applied in the field of wearable objects, can solve the problems of odor-causing bacteria in the shoe interior, the inability of the shoe to allow the free flow of air through the inside of the shoe, and the athlete's foot and making such shoes smell, so as to reduce, if not eliminate, the pressure on the wearer's spine, knees, and other joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

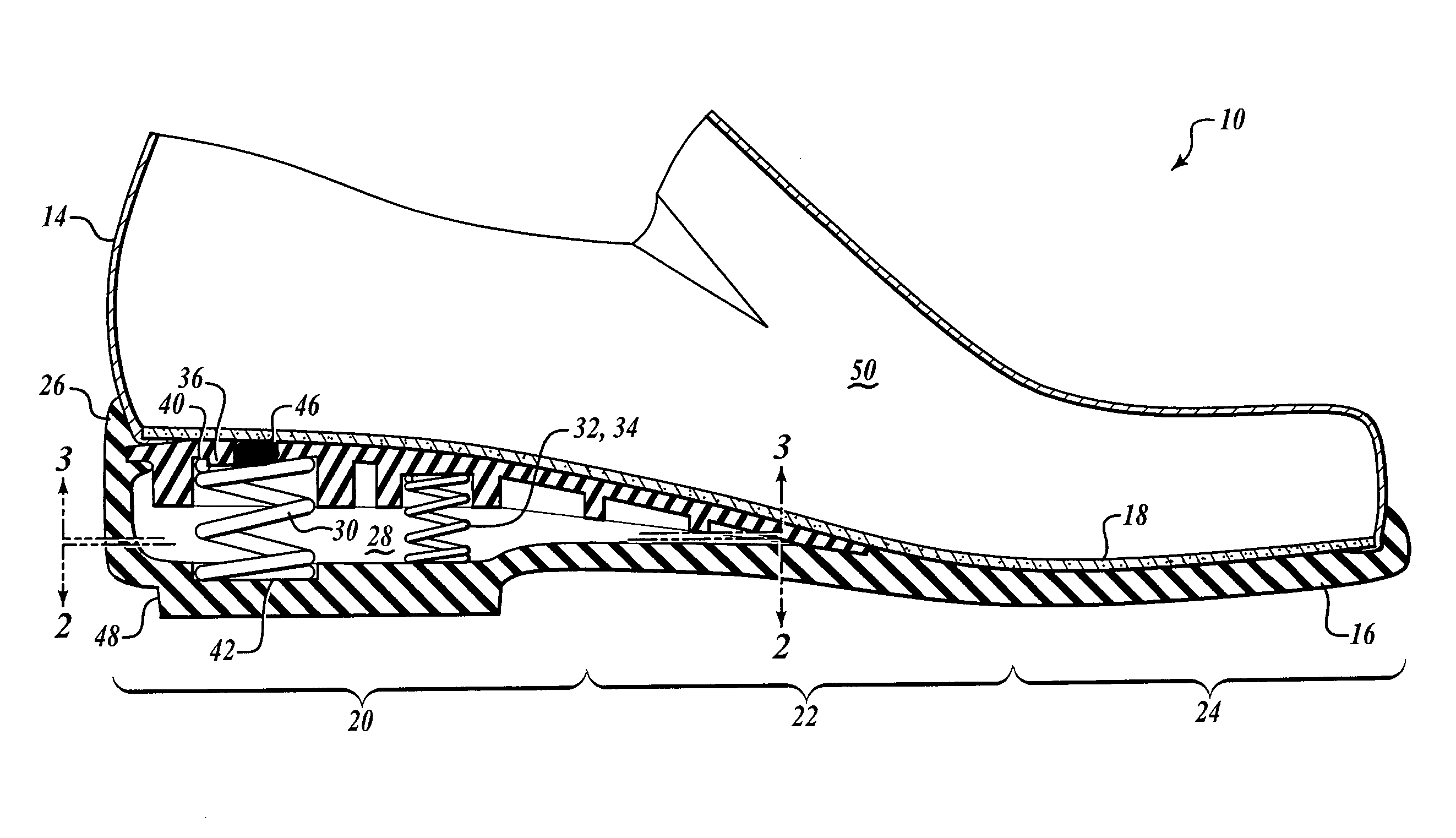

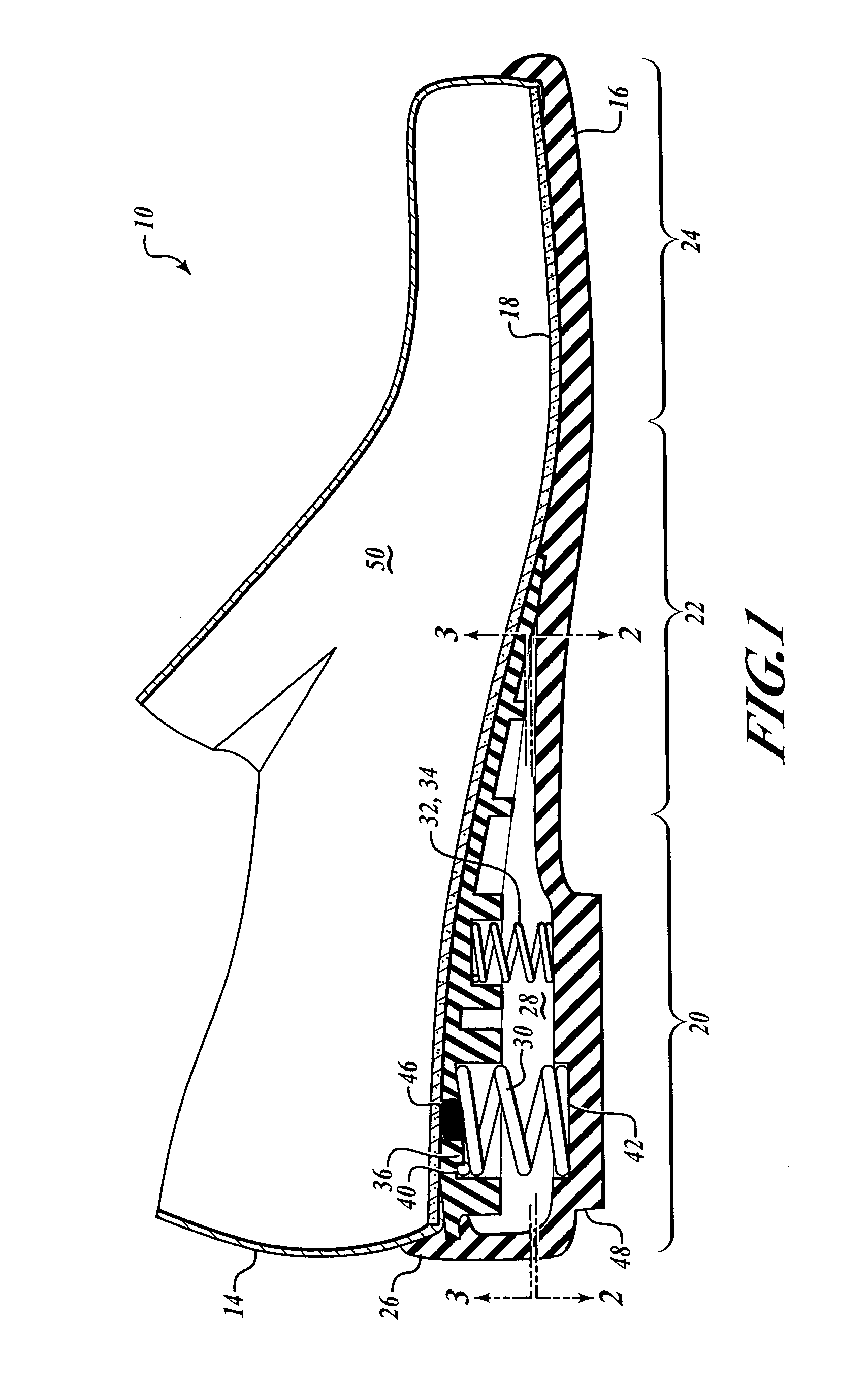

[0024]FIG. 1 shows an embodiment of the shoe 10 with upper 14 and lower 16 joined along the upper sole 18 extending through the heel portion 20, instep portion 22, and toe portion 24. The blended heel 26 defines a cavity 28 that extends from the rearmost point of the heel portion 20 forward under the instep portion 22. The blended heel 26 is made from a resilient material, typically rubber so the cavity walls offer some resiliency, but other resilient materials known to persons skilled in the art are within the scope of the present invention.

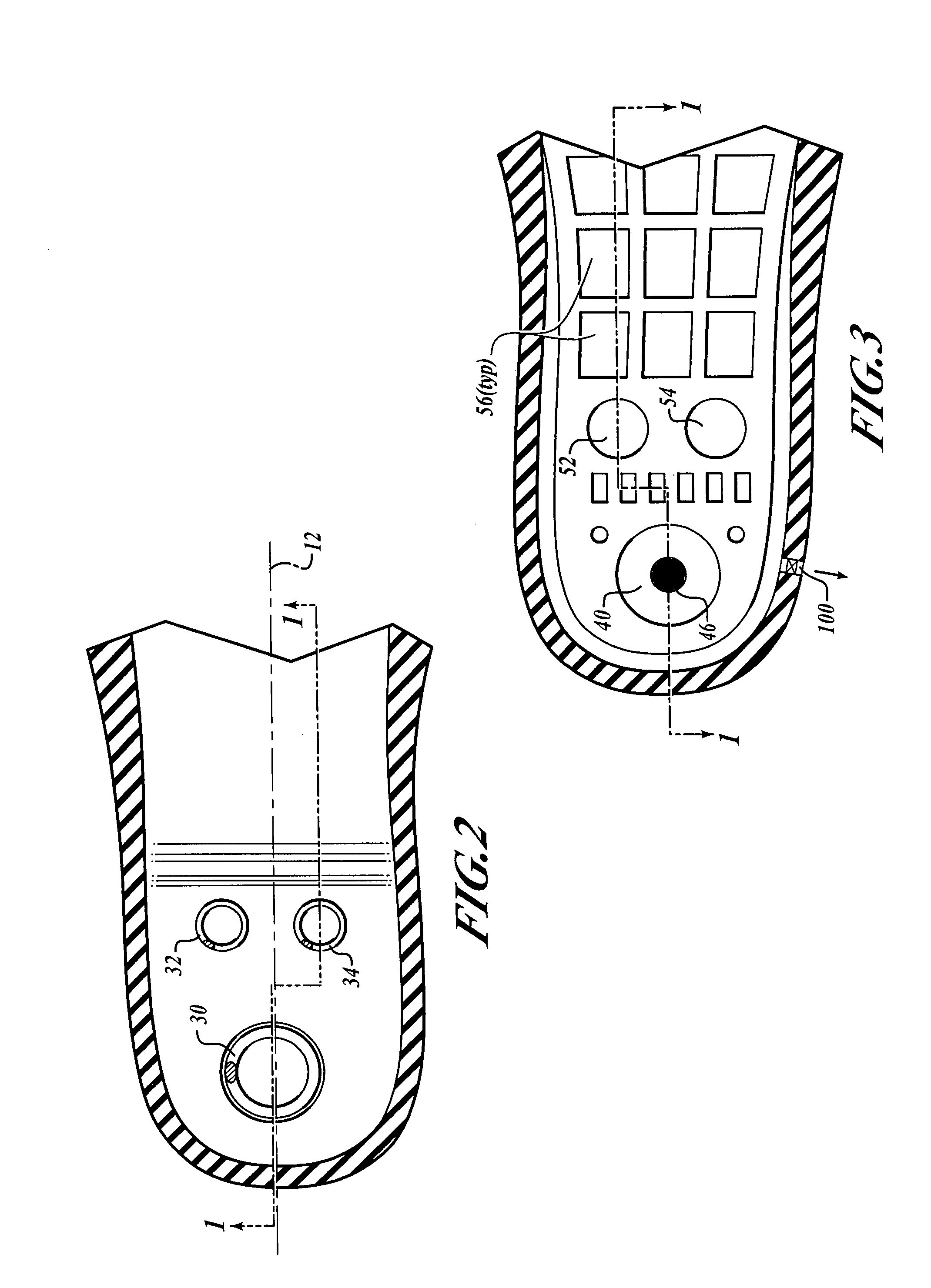

[0025]Two separate materials may be used, as is shown here, with the layer adjacent the upper sole of a softer material than the remainder of the heel. The mainspring 30 is positioned orthogonal to the longitudinal axis 12, as shown in FIG. 2, and under the heelstrike point of the interior of the shoe. The mainspring 30 may be secured by lugs 36 (upper) and 38 (lower; not shown) set into recesses 40 and 42, and provides the majority of resilient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com