Deep ploughing, deep scarification and ridge smashing device

A powder ridge and subsoiling technology, which is applied in the fields of farming machinery, application, agricultural machinery and machinery, etc., can solve the problems of low farming efficiency, incomplete cutting of large pieces of soil, and poor powder ridge effect, so as to improve farming efficiency , increase the crushing effect, and the powder ridge effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

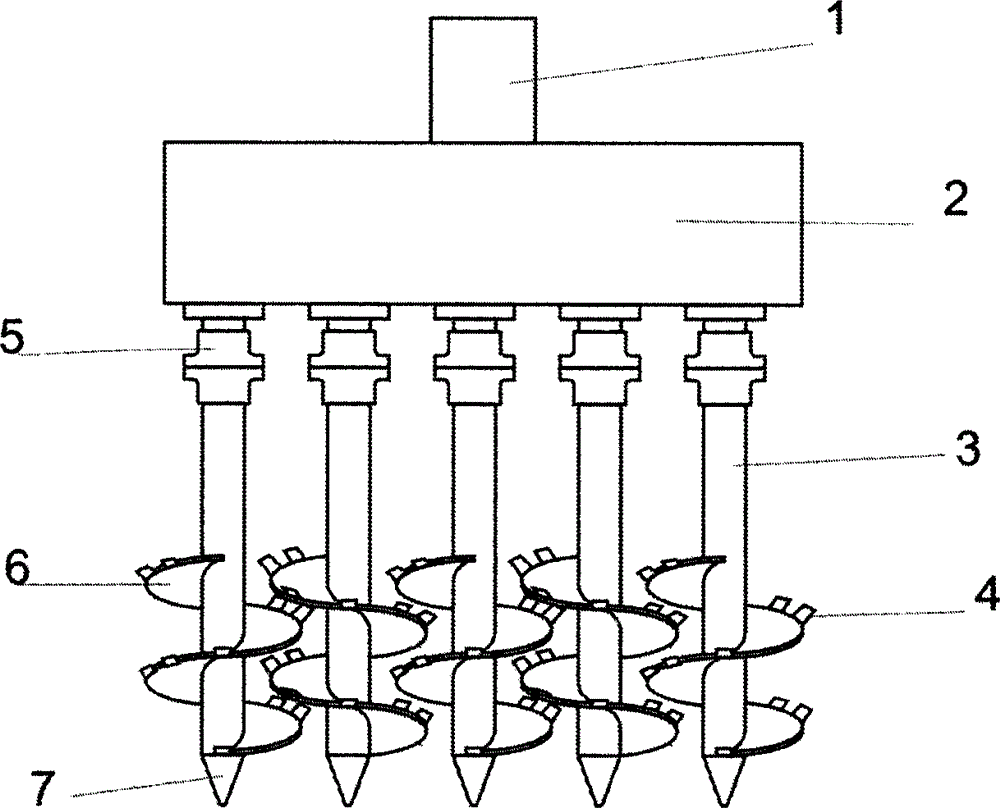

[0019] A deep plowing and loosening powder ridge device, the device includes a hydraulic motor 1, a transmission box 2 and four powder ridge drill bits, the powder ridge drill bit includes a screw shaft 3, a powder ridge knife 4, and the power of the hydraulic motor is transmitted to the powder ridge through the transmission box drill. The top of the screw shaft is provided with a connecting flange 5, a screw blade 6, and a drill tip 7; the screw blade 6 is installed on the screw shaft 3, and the outer edge of the screw blade is provided with a powder ridge knife 4, and the spiral shaft centers of two adjacent powder ridge drill bits The distance is 40cm, the radius of the spiral shaft is 4cm, the vertical distance from the powder ridge cutter head to the edge of the spiral leaf is 6cm, the radius of the spiral blade is 20cm, and the two powder ridge drill bits alternately rotate.

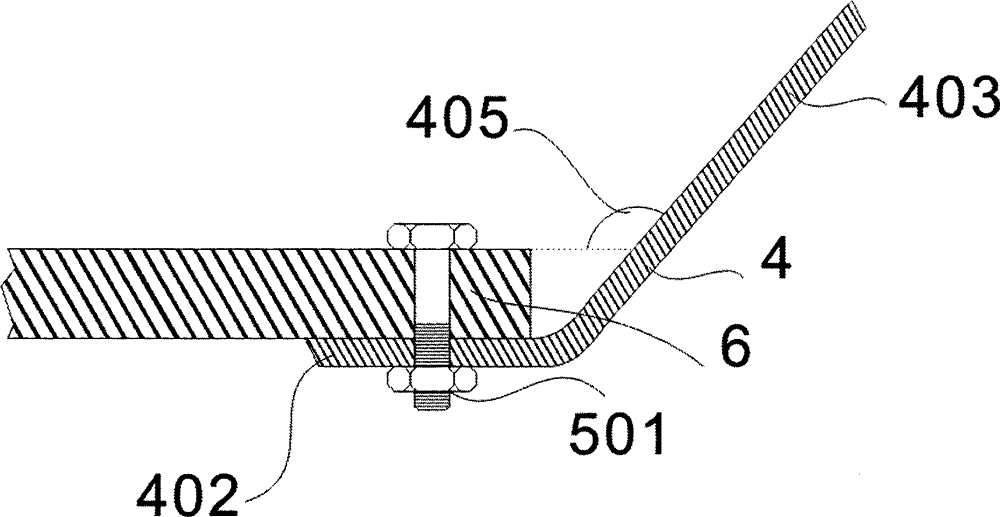

[0020] The powder ridge cutter 4 is composed of a connecting portion 402 and a cutter portion 4...

Embodiment 2

[0022] A deep plowing and loosening powder ridge device, the device includes an electric motor 1, a transmission box 2 and four powder ridge drill bits, the powder ridge drill bit includes a screw shaft 3, a powder ridge knife 4, and the power of the hydraulic motor is transmitted to the powder ridge through the transmission box drill. The top of the screw shaft is provided with a connecting flange 5, a screw blade 6, and a drill tip 7; the screw blade 6 is installed on the screw shaft 3, and the outer edge of the screw blade is provided with a powder ridge knife 4, and the spiral shaft centers of two adjacent powder ridge drill bits The distance is 50cm, the radius of the spiral shaft is 4cm, the vertical distance from the powder ridge cutter head to the edge of the spiral leaf is 6cm, the radius of the spiral blade is 16cm, and the two powder ridge drill bits alternately rotate.

[0023] The powder ridge cutter 4 is composed of a connection part 402 and a cutter part 403, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com