Hub polishing and lapping machine

A technology for a grinding machine and a wheel hub, applied in the field of wheel hubs, can solve the problems of poor grinding and cutting process effect, unsatisfactory polishing speed, and increased machine manufacturing cost, and achieve the effect of speeding up polishing speed, improving effect and efficiency, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

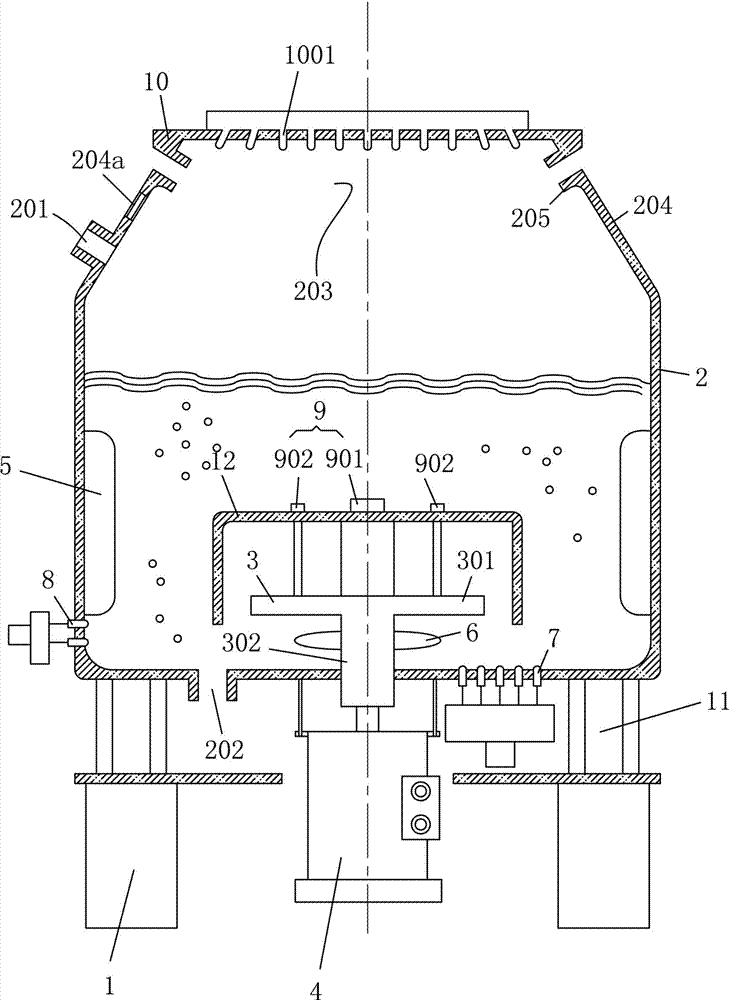

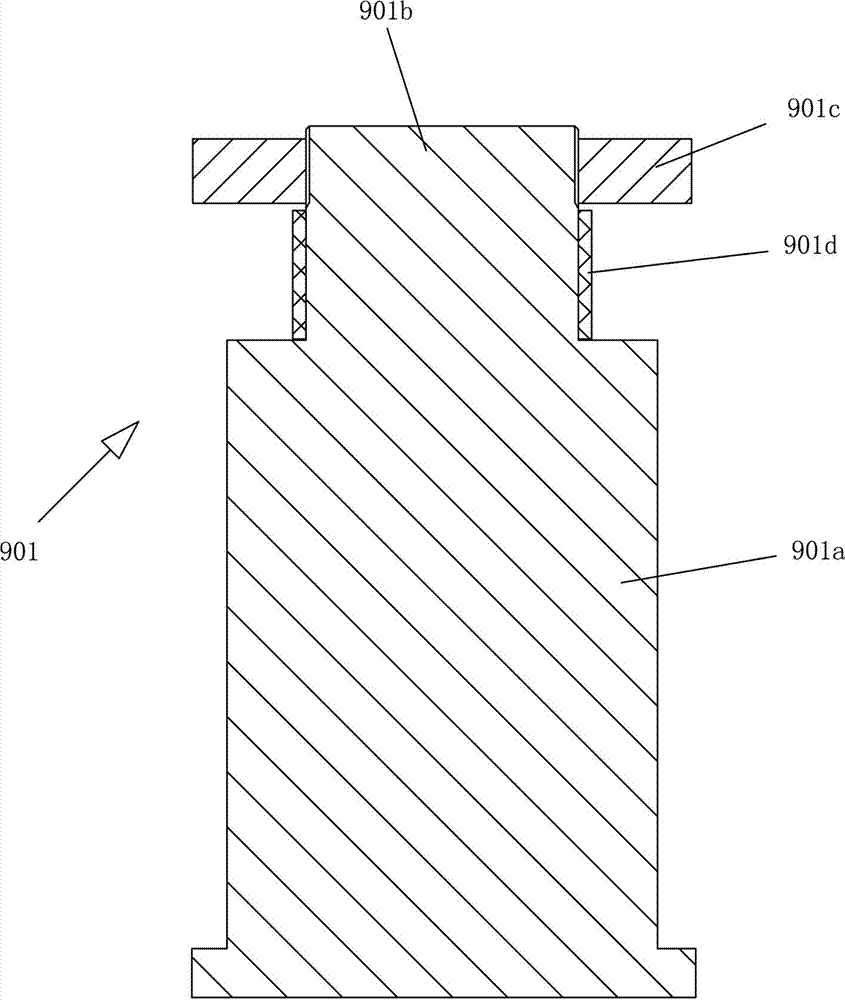

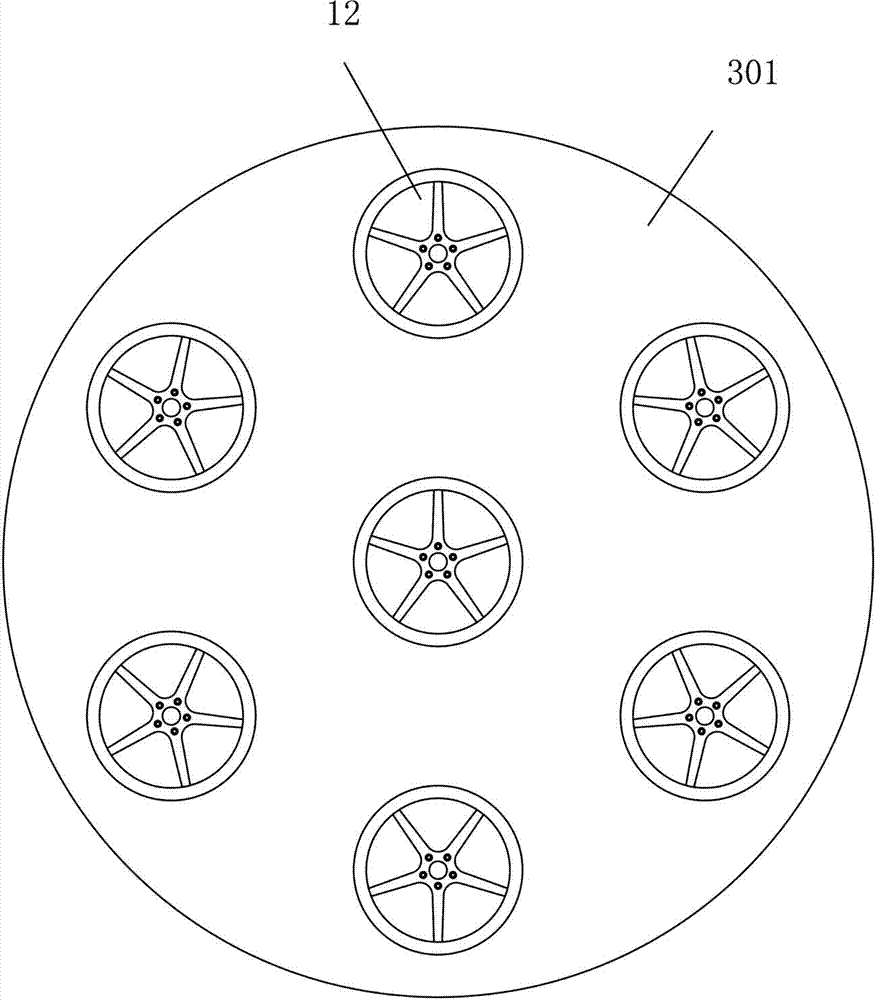

[0044] Examples, see attached figure 1 , 2 , 3, a kind of hub polishing grinder, comprise base 1, be installed on the base 1 and have the abrasive barrel 2 of feeding port 201, feeding port 202 and opening 203, feeding port 202 is used for adding abrasive material, discharging The mouth 202 is arranged on the bottom of the abrasive barrel 2, and can be sealed with a plug etc. at ordinary times, and is used for discharging abrasives when needed. A flywheel disc 3 is installed at the bottom of the abrasive barrel 2, and the upper surface of the flywheel disc 3 is arranged on the upper surface of the abrasive barrel. The hub is fixed on the fixing device 9 on the flywheel disc 3 and the rotating motor 4 used to drive the rotation of the flywheel disc 3. The rotating motor 4 is located outside the abrasive barrel 2 and is fixed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com