Universal side milling head for milling square rams

A square ram, side milling head technology, applied in milling machine equipment, details of milling machine equipment, large fixed members, etc., can solve the problems that cannot meet the processing requirements, the C axis of the milling head cannot be indexed, etc., and achieves compact structure and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

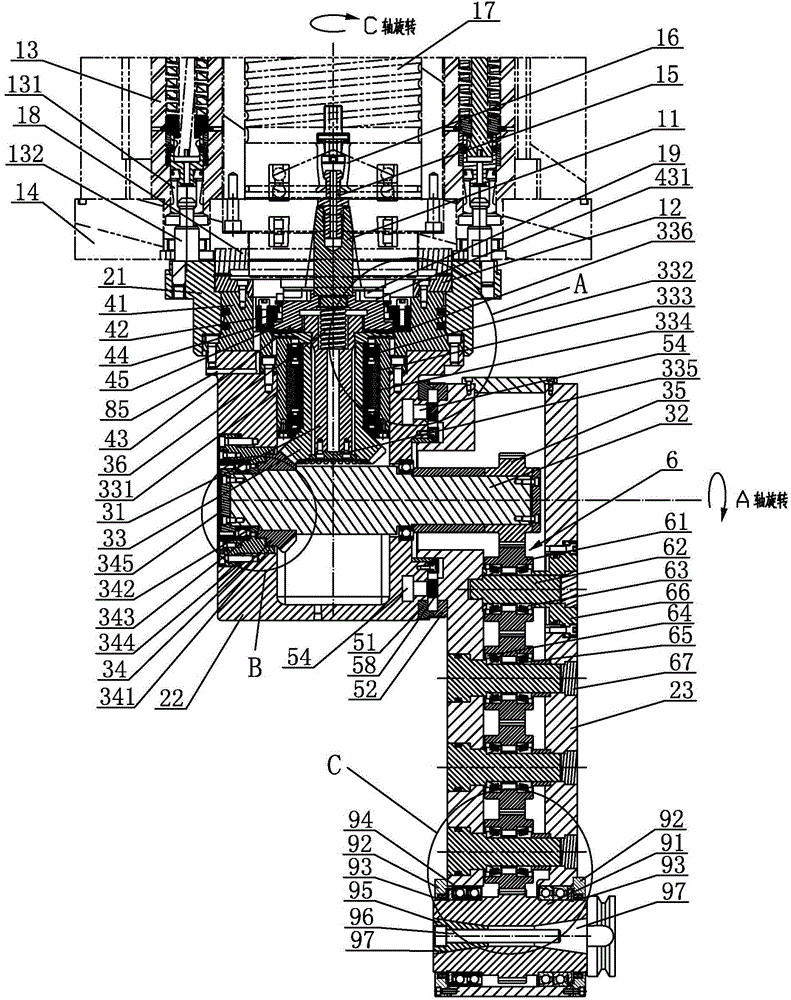

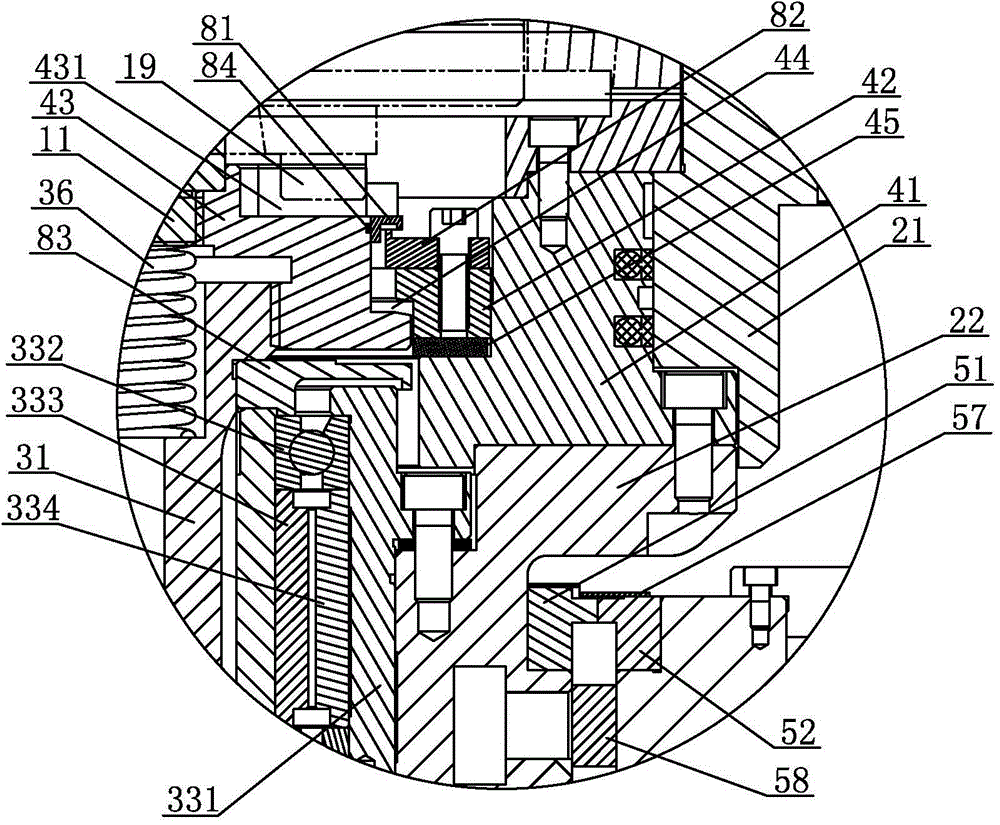

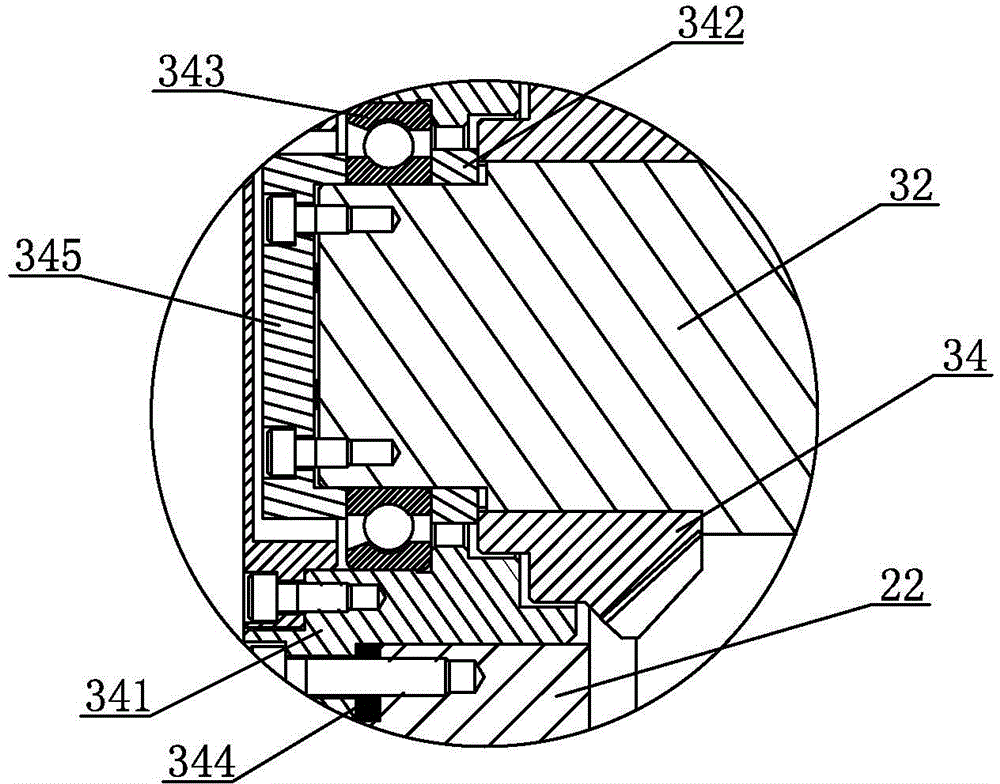

[0030] A square ram universal side milling head as shown in the figure includes a taper shank 11, a lower tooth plate 12, an upper box 21, a lower box 22, a spindle box 23, a transmission mechanism, a C-axis automatic indexing mechanism, A-axis manual indexing locking mechanism, cooling mechanism and waterproof mechanism, the upper box body 21 is centrally connected with the lower crankset 12, and the upper box body 21 is provided with four sliders and cylinder pull nails 132, and the upper box body 21 passes through four The pull stud 132 of the slider oil cylinder is connected with the ram oil receiving plate 14 of the slider oil cylinder 13, and the ram oil receiving plate 14 is connected with the upper tooth plate 18 centeringly. When the machine tool grabs the automatic extension head, the upper tooth plate 18 and the lower tooth plate Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com