Polycrystalline diamond milling cutter

A polycrystalline diamond, milling cutter technology, applied in milling cutters, milling machine equipment, metal processing equipment and other directions, can solve the problems of low productivity, continuous processing, low yield, etc., and achieve the effect of solving the problem of sticking tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

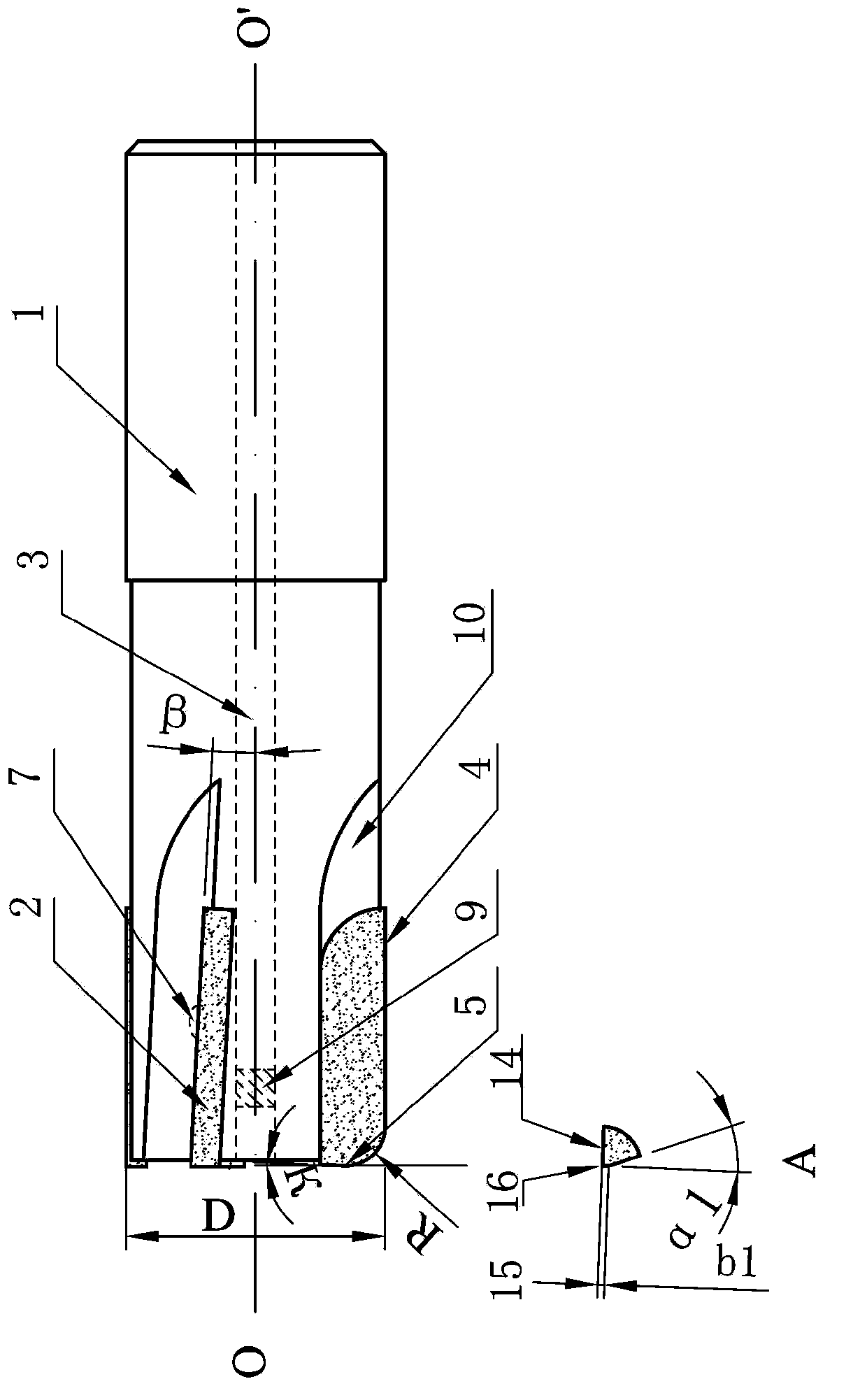

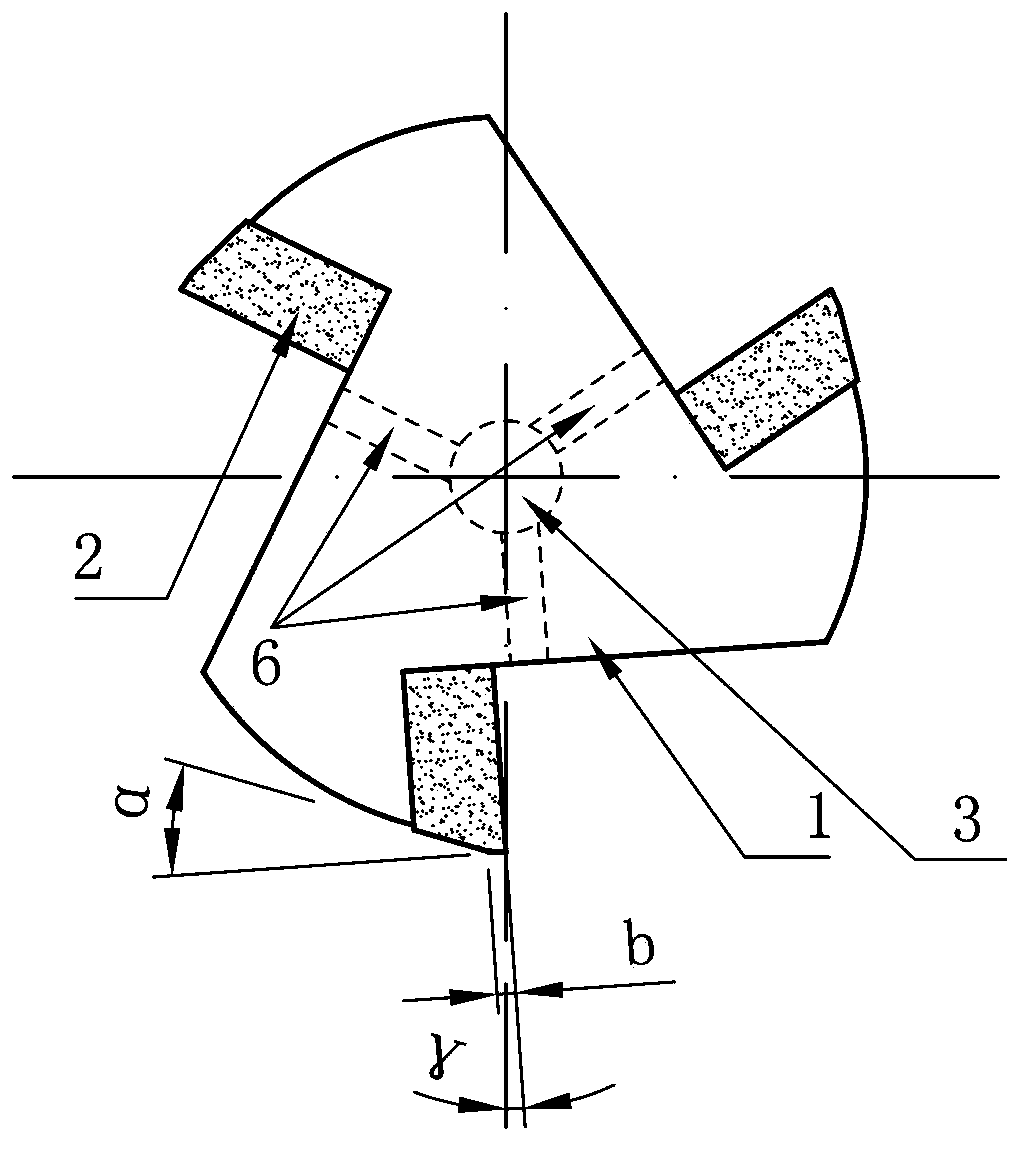

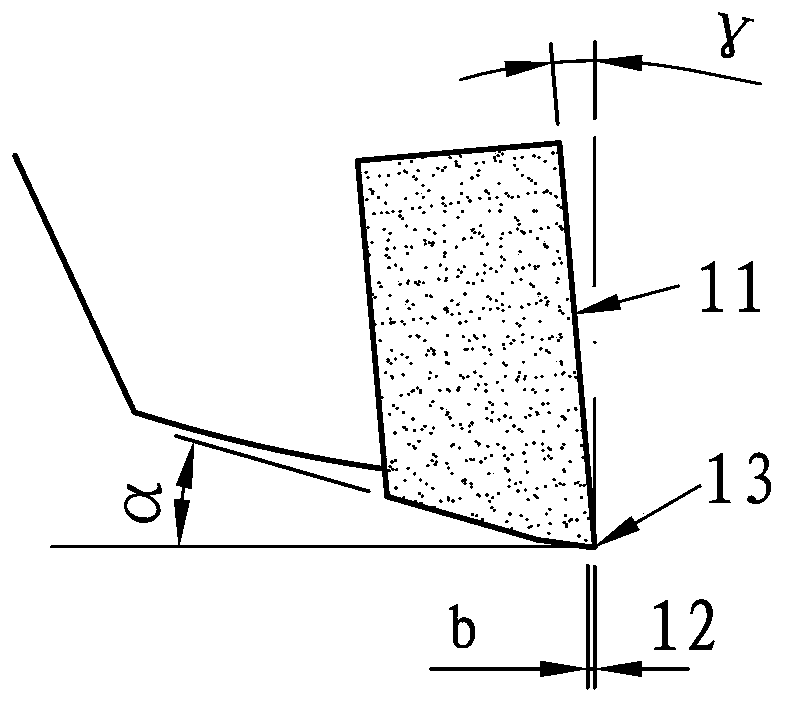

[0022] A schematic solution of the milling cutter of the present invention will now be described with reference to the following specific embodiments in conjunction with the accompanying drawings. Although the drawings are provided to illustrate some embodiments of the invention, the drawings are not necessarily to scale and certain features may be enlarged, removed, or sectioned to better illustrate the invention.

[0023] In addition, unless otherwise specified, certain directional terms in the present invention shall be based on the understanding of those skilled in the art. For example, the "front" and "rear" positions in the components of the milling cutter are determined according to the direction of rotation of the milling cutter. In addition, regarding the definition of "axial", "radial" and "circumferential", it is generally considered that the extension direction of the central axis of the milling cutter is the axial direction, and the direction passing through the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com