Lead-cadmium-free glass powder and preparation method thereof, and conductive aluminum paste and preparation method thereof

A conductive silver paste, lead-free cadmium technology, applied in the field of conductive silver paste and its preparation, lead-cadmium-free glass powder and its preparation, can solve the problem of poor corrosion resistance of conductive silver paste, affecting the performance and life of the windshield, and easy aging and other problems to achieve the effect of improving ball milling efficiency, shortening ball milling time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

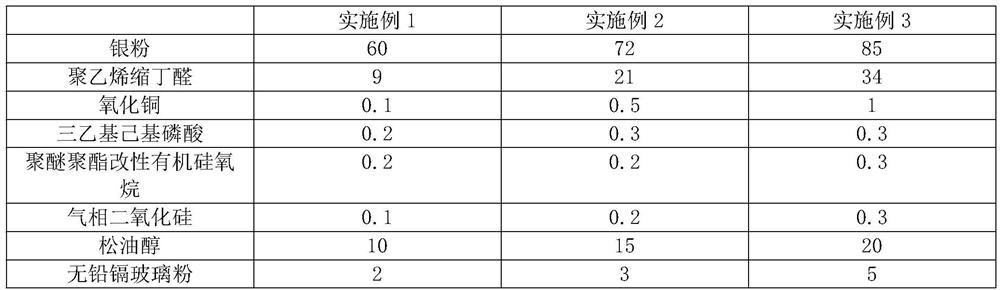

Examples

preparation example 1

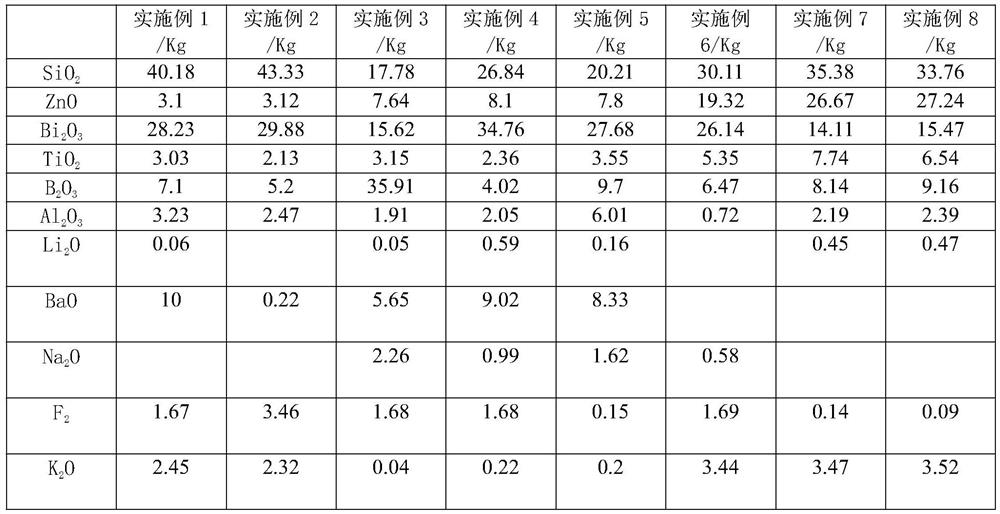

[0051] The preparation methods are the same in Preparation Examples 1-8, except that the amounts of raw materials are different (see Table 1 for details). The following takes Preparation Example 1 as an example for illustration.

[0052] A kind of lead-free cadmium glass frit disclosed in embodiment 1 of the present invention is prepared through the following steps:

[0053] S1. Weigh and mix the raw materials in corresponding parts by weight, and keep warm at 1000°C for 3 hours to obtain molten glass;

[0054] S2. Pour the glass liquid into water to quench, then add alcohol, ball mill to 1 μm, and dry to obtain lead-cadmium-free glass powder.

[0055] Table 1 Composition and dosage of lead-free cadmium glass powder

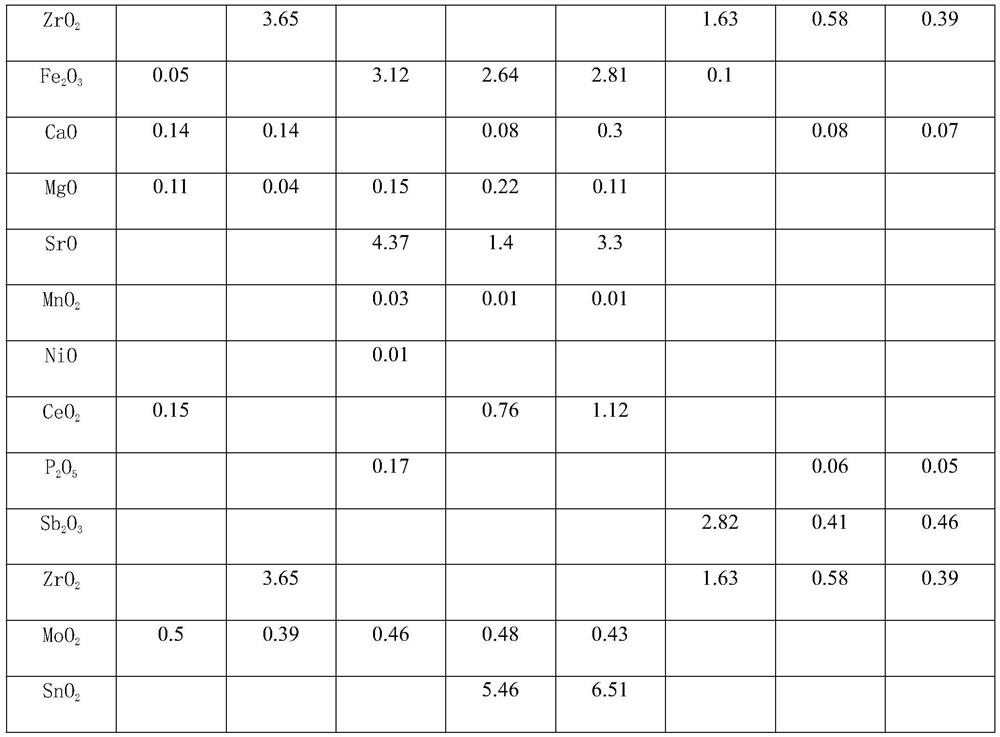

[0056]

[0057]

preparation example 9

[0058] Preparation Example 9 differs from Preparation Example 1 in that:

[0059] After the raw materials are evenly mixed, keep warm at 1150°C for 2.5 hours to obtain molten glass, then pour the molten glass into water to quench, then add alcohol, ball mill to 2 μm, and dry to obtain lead-free cadmium glass powder

preparation example 10

[0060] Preparation Example 10 differs from Preparation Example 1 in that:

[0061] After the raw materials are evenly mixed, keep warm at 1200°C for 2 hours to obtain molten glass, then pour the molten glass into water to quench, then add alcohol, ball mill to 3 μm, and dry to obtain lead-free cadmium glass powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com