Novel disc type flexible grinding wheel machining tool

A processing tool and flexible technology, applied in the field of self-adaptive pressure controllable grinding wheel, can solve the problems of low fixation force of free abrasives, strong mobility of abrasive grains, low processing efficiency, etc., to improve self-adaptive profiling ability and pressure, high Material removal rate, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

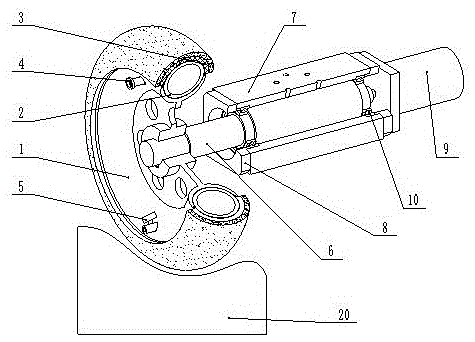

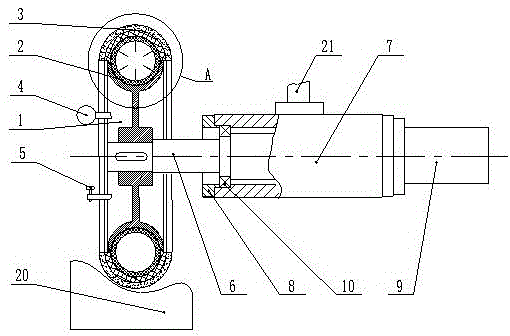

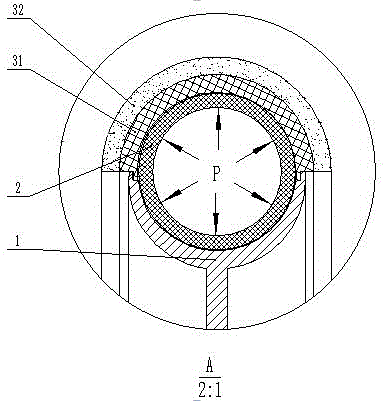

[0018] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0019] A new type of disc-type flexible grinding wheel processing tool, including: grinding wheel hub 1, pressure holding wheel 2, flexible rubber-based grinding wheel 3, pressure monitor 4, pressure regulating valve 5, rotating shaft 6, connecting seat 7, bearing end cover 8, The driving motor 9 and the bearing 10 are characterized in that: the grinding wheel hub 1 is installed on the output end of the rotating shaft 6 through a flat key, the pressure holding wheel 2 is installed on the grinding wheel hub 1, and the flexible rubber-based grinding wheel 3 is installed and fixed on the grinding wheel hub 1 through S-shaped barbs, the rotating shaft 6 is installed inside the connecting seat 7 through the bearing 10 and the bearing end cover 8, and the driving motor 9 is connected with the rotating shaft 6 to drive The rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com