Diamond bit with large saw-teeth

A diamond drill bit and serrated technology, which is applied in the field of large serrated diamond drill bits for drilling, can solve the problems of single tooth shape, easy slipping of the drill bit, poor adaptability to different rock formations, etc., achieve good cutting force and durability, and facilitate flushing without jamming Good effect of drilling and adaptability

Inactive Publication Date: 2013-07-03

GUILIN DIAMOND IND TECHN

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The tooth-type diamond drill bit commonly used at present is surrounded by a ring of tooth-like protrusions on the top of the drill bit (similar to the shape of the city wall of the Great Wall). When rotating at high speed, it produces a plow-type cutting effect. Still not good enough, with low time efficiency, and poor adaptability to different rock formations; such as hard and dense weakly abrasive formations, the drill bit is easy to slip during the drilling process, fine coal powder is easy to stick, and the timeliness is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

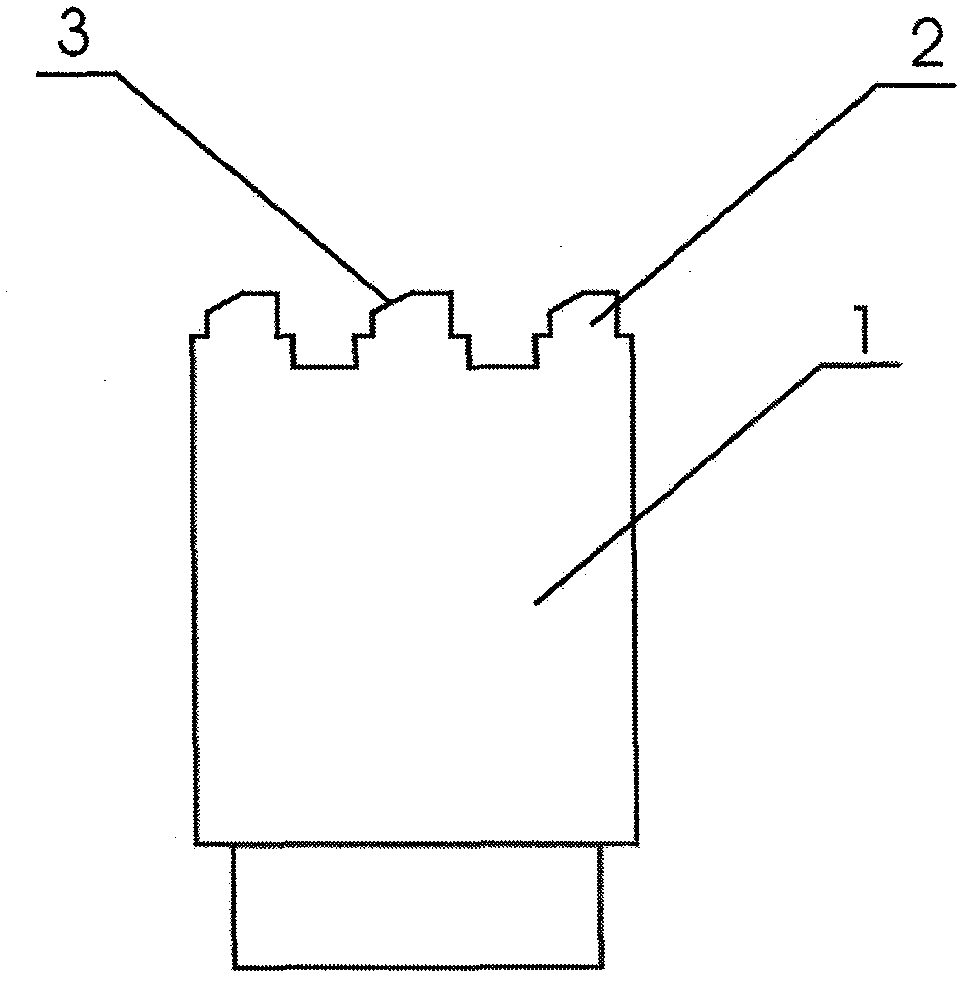

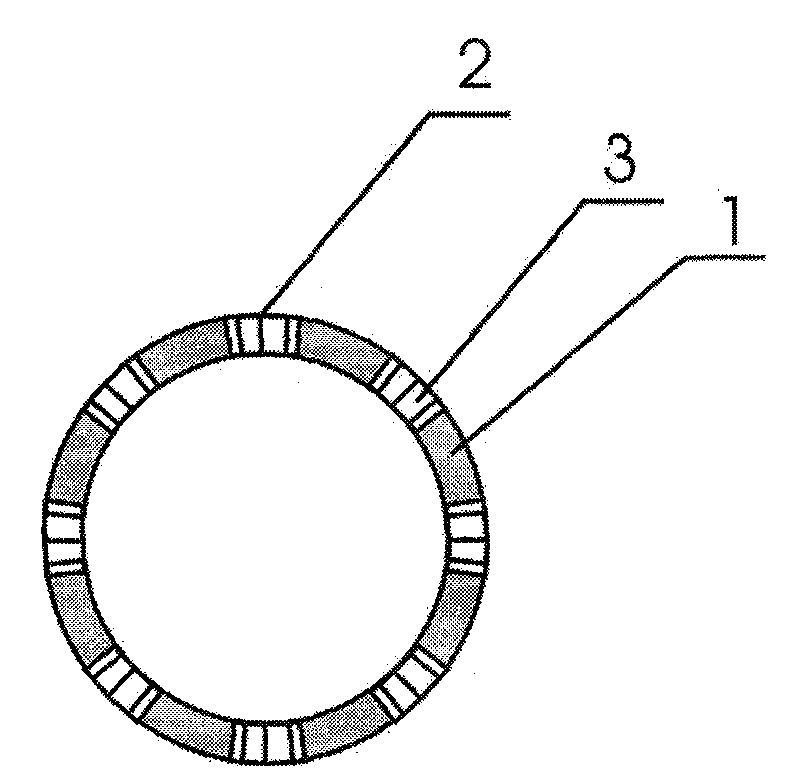

[0012] exist figure 1 and 2 Among them, the present invention includes a body 1 and drill teeth 2, the drill teeth 2 are in the shape of a polygonal convex zigzag, with a slope 3 arranged at the top of the body 1 and arranged in a circle at the top of the body 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention aims to provide a diamond bit with large saw-teeth, which is good in cutting force and durability, high in effectiveness for a given period of time, pipe-sticking avoidance, and good adaptive capacity for weak abrasive formation. The diamond bit comprises a body and drill teeth, wherein the drill teeth adopt a polygonal shape or a convex saw-toothed shape, and are annularly arranged at the top end of the body; and an inclined plane is formed at the top end of each drill tooth.

Description

technical field [0001] The invention relates to a large serrated diamond drill bit for drilling. Background technique [0002] In industries such as mining, coal mining and oil field mining, the drill bits used in geological drilling generally use diamond drill bits, and the diamond particles are attached to the cutting surface of the drill bit by inlaying sintering or electroplating. The whole drill bit has no moving parts and has a relatively simple structure. , with high strength, high wear resistance and impact resistance, is one of the three new technologies of drilling in the world in the 1980s. Field use proves that when drilling in soft-medium hard formations, diamond bits have the advantages of fast speed, more footage, long life, stable work, fewer downhole accidents, and good wellbore quality. The diamond drill bit not only has a long service life, but also can be reused. The diamond drill bit returned to the factory for repair has the same effect as the factory ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B10/46

Inventor 不公告发明人

Owner GUILIN DIAMOND IND TECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com