Turning, milling and drilling comprehensive numerical control equipment

A kind of numerical control equipment, drilling and tapping technology, applied in turning equipment, turning equipment, metal processing equipment and other directions, can solve the problems of delaying business opportunities, loss of machining accuracy of parts, etc., to reduce the type and quantity, high machining accuracy, and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

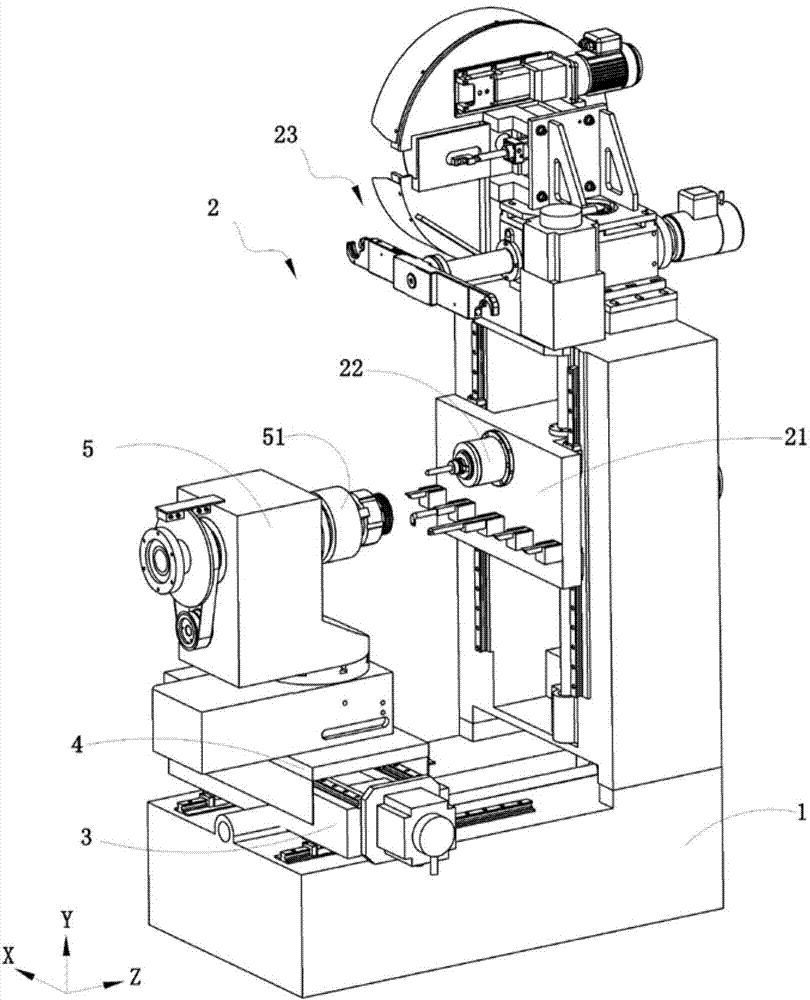

[0027] Such as figure 1 The shown comprehensive numerical control equipment for turning, milling, drilling and tapping includes: a machine base 1 , a machining tool device 2 , a workbench base 3 , a workbench 4 and a rotating spindle seat 5 .

[0028] The base 1 has a Z-axis driving device 11 and a Y-axis driving device 12 .

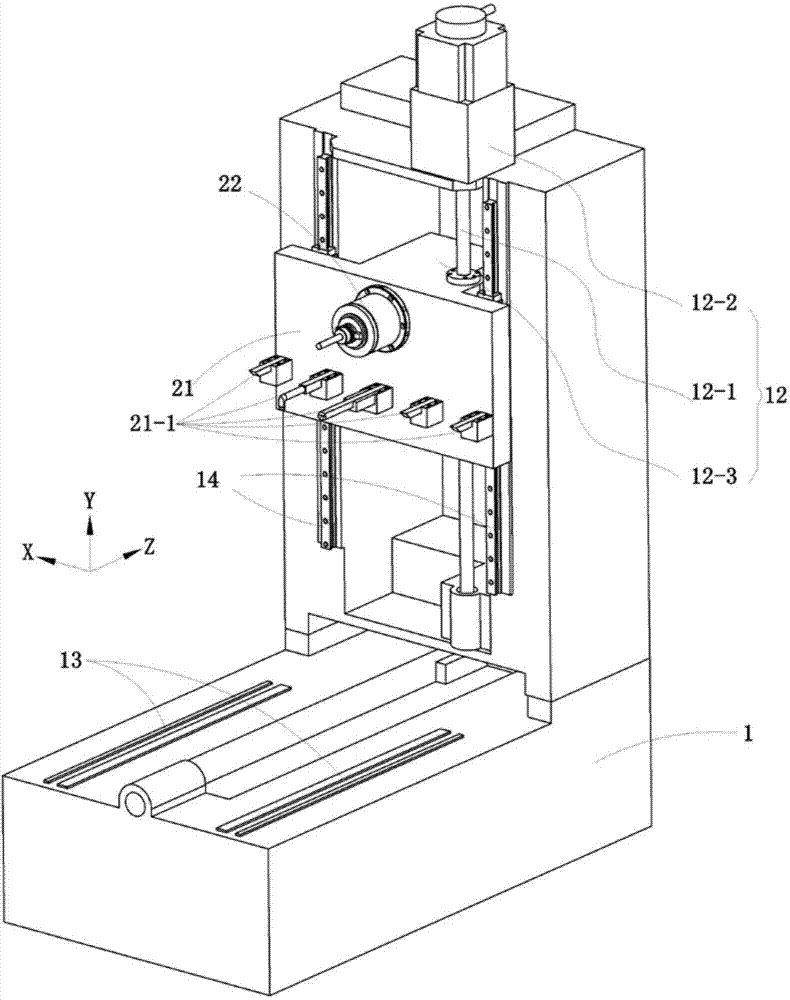

[0029] Such as image 3 As shown, the processing tool device 2 includes a tool seat 21 installed on the Y-axis driving device 12 , the tool seat 21 can move along the Y-axis, and a processing tool is installed on the tool seat 21 . The machine base 1 is provided with a Y-guiding rail 14 , and the bottom of the tool holder 21 is slidably connected with the Y-guiding rail 14 . The Y-axis driving device 12 includes a Y-direction drive screw 12-1 fixedly installed on the machine base 1 and a motor 12-2 for driving the Y-direction drive screw 12-1. 12-1 is provided with a Y-direction nut seat 12-3 that can slide along the Y-direction, and the Y-direction n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com