Multi-wire saw for cutting high-hardness materials

A multi-wire cutting machine and multi-wire cutting technology, applied in stone processing equipment, fine working devices, working accessories, etc., can solve the problems of inability to cut superhard materials, small swing range, low cutting speed, etc., and achieve low cost , the cutting effect is enhanced, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

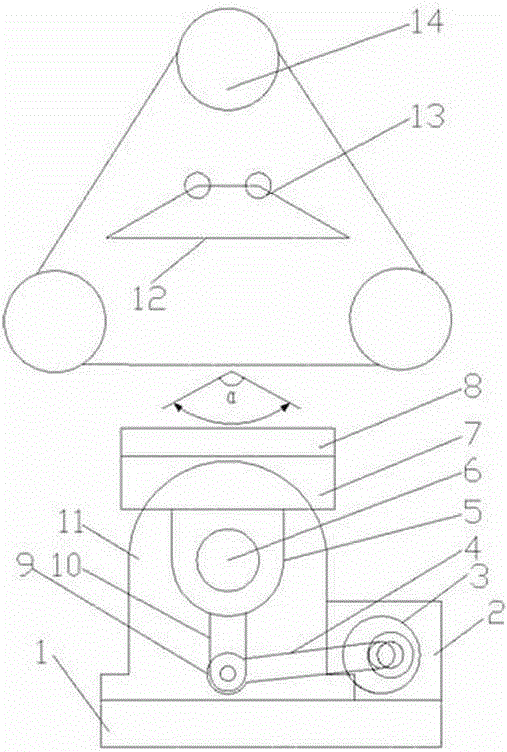

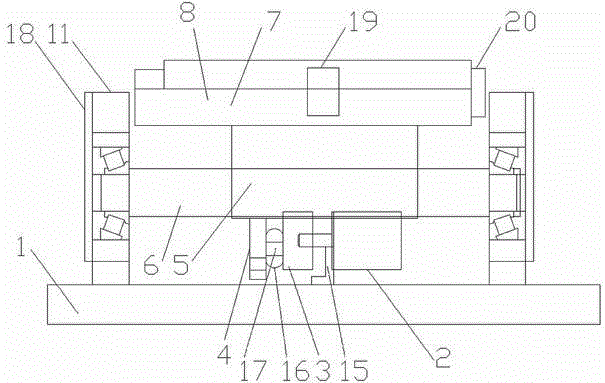

[0024] figure 1 and figure 2 A specific embodiment of the present invention is shown. As shown in the figure, a multi-wire cutting machine for cutting high-hardness materials includes a worktable 7 on which a material plate 8 is placed, and multiple wire cutting machines are arranged above the workbench. Wire cutting mechanism, the workbench 7 swings under the drive of the swing assembly; the multi-wire cutting mechanism includes three sheaves 14 distributed in a character shape, and the cutting wire is wound on the sheave 14; the swing assembly includes a lifting body 1. A pair of bearing housings 11 are installed on the lifting body 1, and the two ends of the central shaft 6 are rotatably installed in the bearing housings 11; the central shaft 6 is fixed on the part between the two bearing housings 11 to fix the bearing bush 5 and the bearing bush 5 The top is fixed to the bottom of the workbench 7; the bottom of the bearing bush 5 is fixedly mounted with a swing rod 10, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com