NdFeB permanent magnetic material processing method and device

A permanent magnet material and processing method technology, applied in the field of material processing, can solve the problems of low processing accuracy, low single-machine processing volume, and high inspection cost, and achieve the effects of low processing accuracy, high inspection cost, and omitting inspection procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

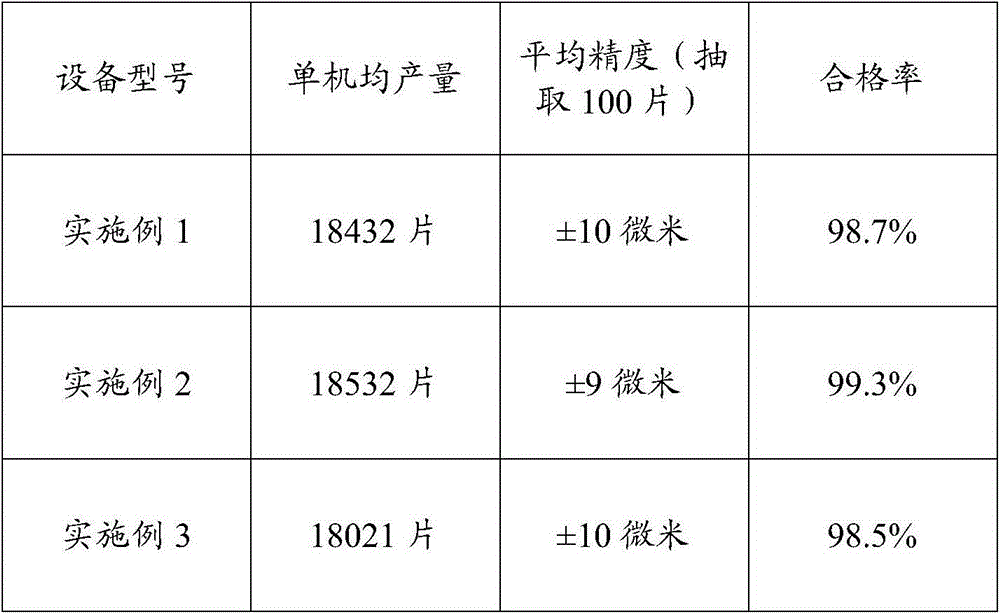

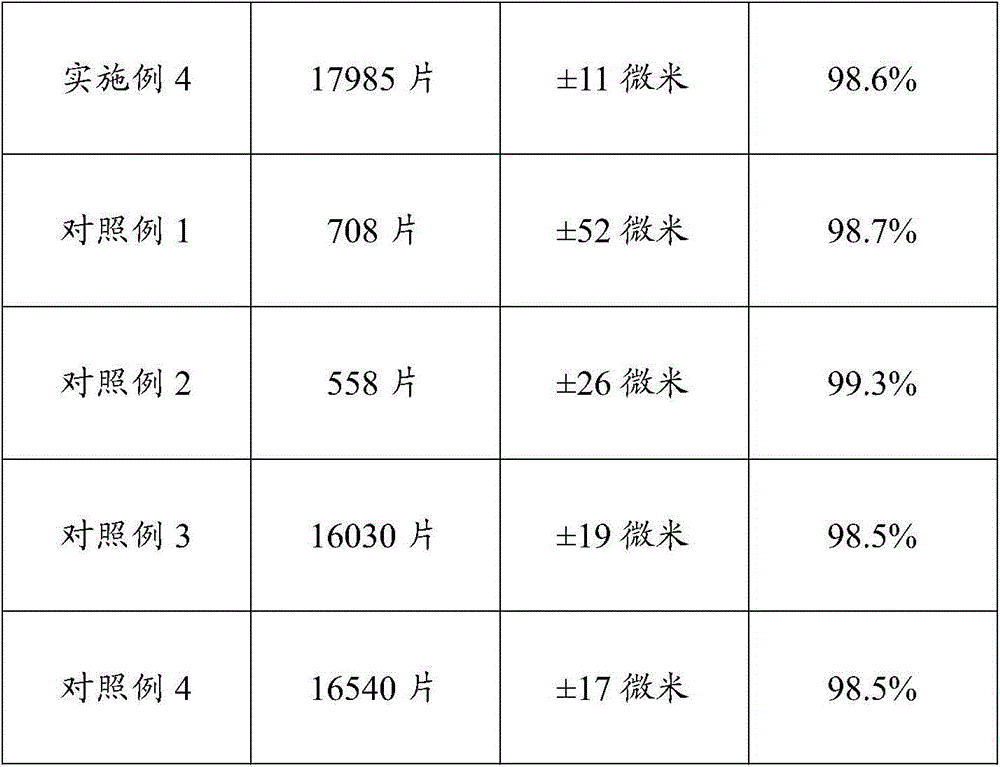

Examples

Embodiment 1

[0014] 1) Bonding step: first use 502 glue to bond the cut glass backing plate to the clean and dry material plate, and at the same time use glue to bond the strips together on the bonding tooling, and then glue the bonded glass The material board is placed on the positioning tool, and finally the bonded strips are bonded on the material board according to the reference positioning.

[0015] 2) Loading step: After the bonding is completed, use a forklift to transfer the bonded whole sheet to the storage rack, and then use a forklift to send the entire sheet to the workbench of the multi-wire cutting equipment. Cut according to the corresponding scheme of the material specification.

[0016] 3) Cutting steps: confirm the cutting zero point, set the cutting parameters, start the cutting program, and then perform arc cutting, line withdrawal and unloading in sequence after the cutting is completed. The cutting parameters are set as:

[0017] Pay-off tension: 10N; take-up tension...

Embodiment 2

[0019] 1) Adhesive step: first use acrylate AB glue to bond the cut plexiglass backing plate to the clean and dry material board, and at the same time use glue to bond the strips together on the adhesive tooling, and then glue the The good glass material plate is placed on the positioning tool, and finally the bonded strips are bonded on the material plate according to the reference position.

[0020] 2) Loading step: After the bonding is completed, use a forklift to transfer the bonded whole sheet to the storage rack, and then use a forklift to send the entire sheet to the workbench of the multi-wire cutting equipment. Cut according to the corresponding scheme of the material specification.

[0021] 3) Cutting steps: confirm the cutting zero point, set the cutting parameters, start the cutting program, and then perform arc cutting, line withdrawal and unloading in sequence after the cutting is completed. The cutting parameters are set as:

[0022] Pay-off tension: 40N; take-...

Embodiment 3

[0024] 1) Adhesive step: first use 502 glue to bond the cut glass plate on a clean and dry material plate, and at the same time use glue to bond the strips together on the adhesive tooling, and then glue the bonded glass frit The board is placed on the positioning tool, and finally the bonded strips are bonded on the board according to the reference position.

[0025] 2) Loading step: After the bonding is completed, use a forklift to transfer the bonded whole sheet to the storage rack, and then use a forklift to send the entire sheet to the workbench of the multi-wire cutting equipment. Cut according to the corresponding scheme of the material specification.

[0026] 3) Cutting steps: confirm the cutting zero point, set the cutting parameters, start the cutting program, and then perform arc cutting, line withdrawal and unloading in sequence after the cutting is completed. The cutting parameters are set as:

[0027] Pay-off tension: 25N; take-up tension: 25N, cutting speed 50m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com