Handling method adopted after cutting wire breakage of multi-wire sawing machine

A technology of multi-wire cutting machine and processing method, which is applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of large damage to silicon wafers and scrapping of crystal ingots, so as to improve the success rate, reduce errors, and easily looking for effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

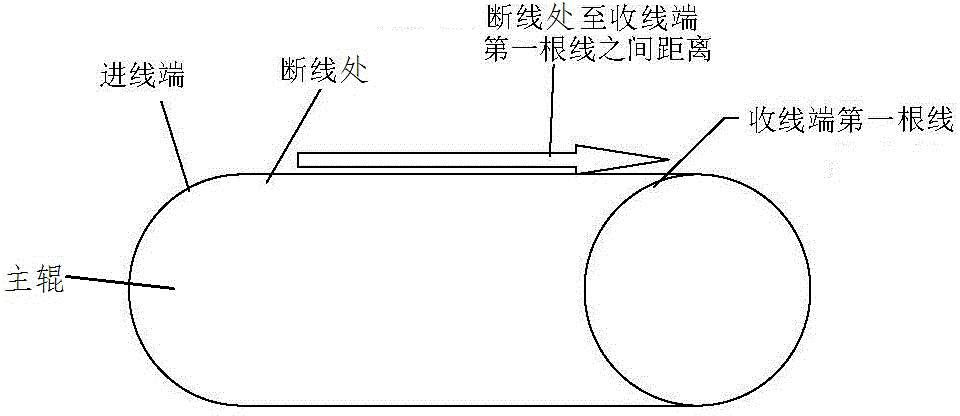

[0018] The following takes the NTC442 cutting machine as an example to introduce the processing method after the cutting wire is broken.

[0019] A treatment method for broken wires of a multi-wire cutting machine. First, sand the diameter of the two ends of the steel wire to 1 / 2 of the original steel wire with coarse sandpaper sold in hardware stores. ~2 / 3, the length of the cutting wire ends in the sanding section is >5cm, then use fine sandpaper to smooth the surface of the steel wires, and finally clean the two steel wire ends with alcohol. Overlap two steel wire heads with 5cm of sand and weld them together. The welded steel wire must have a long section of loose wire. What we need to do in this step is to run this loose steel wire to the guide wheel go up. First raise the workbench by 2mm and open the mortar. Use your fingers to pick up the loose steel wire, and reduce the tension arm at the wire inlet. Turn on the main roller and run the wire at a speed of 0.1m / s until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com