Feeding controlling means for multi-wire saw working bench

A multi-wire cutting machine and feed control technology, applied in the direction of fine work equipment, manufacturing tools, stone processing equipment, etc., can solve the problems of inconvenient maintenance, reduced processing accuracy, complex structure, etc., and achieve easy implementation and improved cutting quality. , the effect of simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

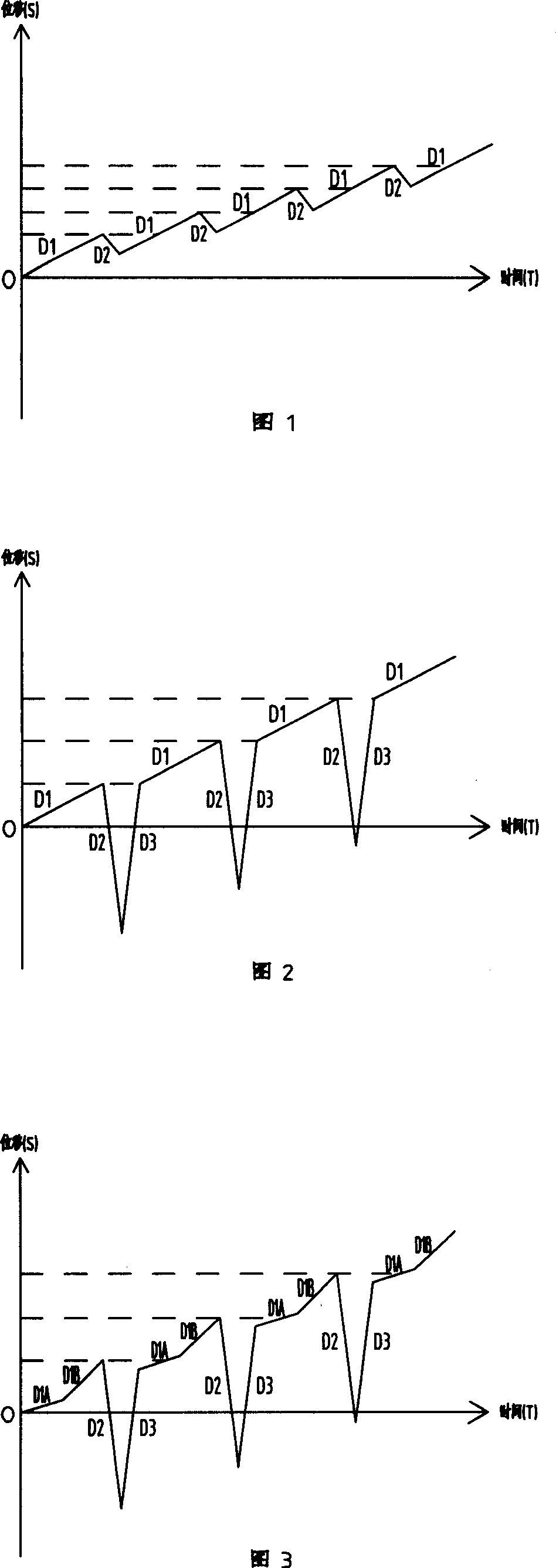

[0017] It can be seen from Figure 1 that the feed cycle of the worktable includes the cutting feed section D1 and the table retreating sand feeding section D2. In order to ensure that the grinding sand is input to the lower part of the contact surface between the steel wire and the cutting workpiece, the displacement of the sand feeding section D2 of the step back is 2-15 times of the grain size of the grinding sand (2 times in this embodiment). After each cutting cycle (steel wire reciprocates once), the workbench descends, the steel wire will bring abrasive sand with a certain viscosity into the slit, and the workbench rises to start the next cutting cycle, and so on.

Embodiment 2

[0019] It can be seen from Figure 2 that in order to further improve the cutting efficiency, the feed cycle of the worktable includes the cutting feed section D1, the table retreating sand entry section D2, and the sand entry recovery section D3. The displacement of the table retreating sand entry section D2 is the abrasive sand particle size 2-15 times (the present embodiment is 10 times) of. The rest are the same as embodiment 1.

Embodiment 3

[0021] It can be seen from Fig. 3 that in order to further improve the cutting efficiency and cutting quality, the feeding cycle of the worktable includes the cutting feeding section D1, the table retreating sand feeding section D2, and the sand feeding completion recovery section D3. The displacement of the table retreating sand feeding section D2 is 2-15 times (the present embodiment is 15 times) of the grain size of the grinding sand. The cutting feed section D1 includes an initial cutting feed section D1A and a normal cutting feed section D1B, and the displacement of the initial cutting feed section D1A is 0.1-0.3 (0.2 in this embodiment) of the displacement of the cutting feed section D1. With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com