Multi-wire sawing machine capable of eliminating arc influence of sawing wires

A multi-wire cutting machine and cutting wire technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, increased processing costs, and long cutting time, so as to improve production efficiency and reduce The effect of reducing the processing cost and shortening the total cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

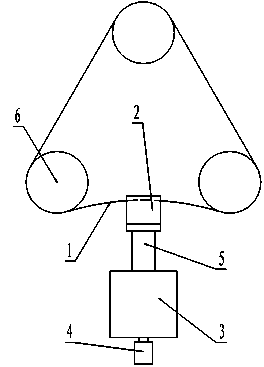

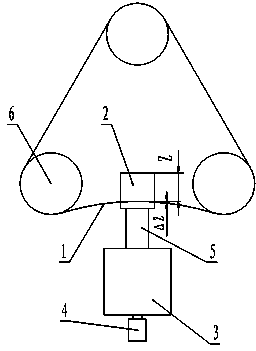

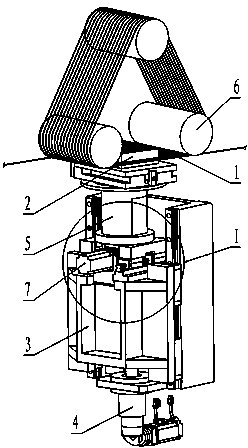

[0021] see Figure 3 ~ Figure 7 , the present invention is provided with a sheave assembly 6, a cutting line 1, a lifting body 3, a lifting drive mechanism 4 and a workbench 5, the cutting line 1 is wound on the roller assembly 6 to form a cutting line network, and the lifting body The lower end of 3 is fitted with the lifting drive mechanism 4, and a worktable 5 is set above the lifting body 3, on which the workpiece 2 to be cut is clamped. A feed mechanism 7 , the horizontal feed mechanism 7 is arranged between the lifting body 3 and the worktable 5 .

[0022] see Figure 3 ~ Figure 6 , the horizontal feed mechanism 7 of the present invention comprises a horizontal feed motor 7-1, a screw nut transmission assembly, a horizontal slide table 7-2 and a horizontal slide rail 7-3, and the horizontal feed motor 7-1 is fixed on the lifting On the body 3, its output shaft is connected with the screw 7-5 of the screw nut transmission assembly, the nut 7-6 of the screw nut transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com