Online monitoring device and method for wire bow of wire mesh of multi-wire sawing machine

A multi-wire cutting machine and monitoring device technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of scrapping of slicing quality ingots, difficult to monitor the influence of wire bows in real time, etc., to prevent wire breakage, Guaranteed cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

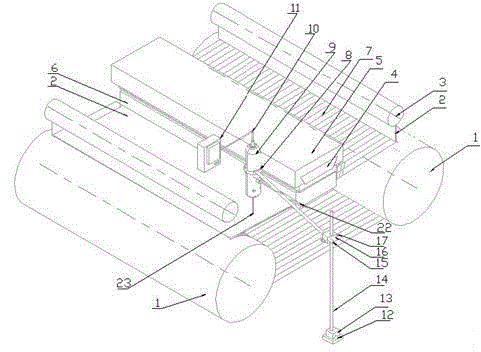

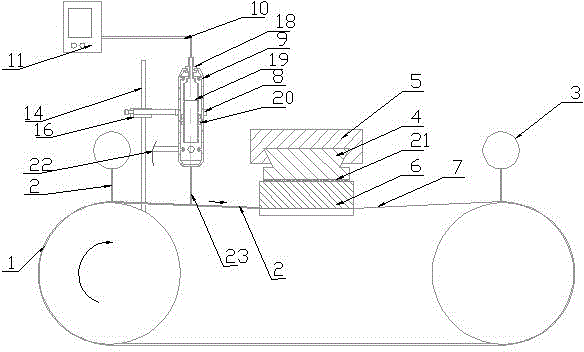

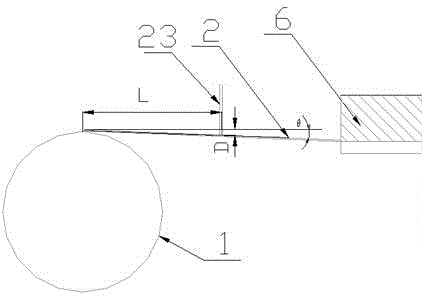

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. In particular, the following examples are only used to illustrate the present application, but not to limit the scope of the present application. This embodiment is a part of the embodiments of the present application, but not all of the embodiments. All other embodiments obtained by persons of ordinary skill in the art without creative efforts belong to the scope of protection of the present application. figure 1 It is a sectional view of the inventive device, figure 2 Invention device structure diagram, image 3 Schematic diagram of wire bow monitoring for the invention device.

[0029] An on-line monitoring device for a wire, net and wire bow of a multi-wire cutting machine, comprising a distance sensor 19; the distance sensor 19 is fixed inside the casing 9 through a lock nut 20; the casing 9 is connected to a protective gas inlet pipe 22; the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com