Intelligent PID control system for roller temperature of multi-wire saw, and control method thereof

A multi-wire cutting machine and control system technology, applied in the direction of temperature control, control/regulation system, temperature control using electric mode, etc., can solve the influence of random noise, PID control is difficult to meet production requirements, shaft and roller temperature control System large hysteresis and other problems, to achieve good adaptability, simple structure, and improve production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

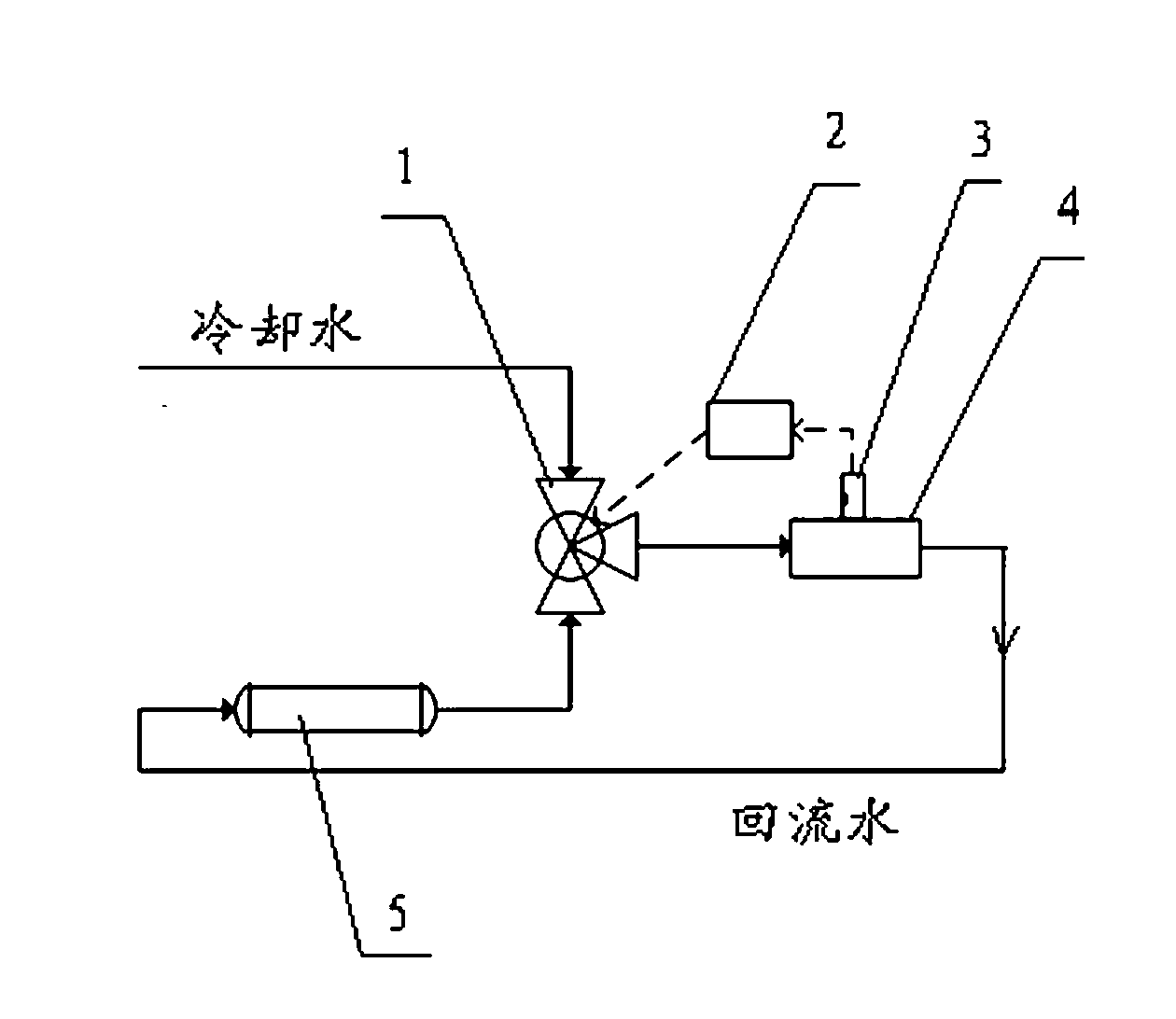

[0028] see figure 1 As shown, the figure shows the system structure of an intelligent PID control system for shaft and roll temperature of a multi-wire cutting machine provided by an embodiment of the present invention. For ease of description, only the parts related to the embodiment of the present invention are shown.

[0029] See figure 1 As shown, an intelligent PID control system for shaft and roll temperature of a multi-wire cutting machine includes:

[0030] A three-way regulating valve 1, the cold water inlet of the three-way regulating valve 1 is connected to the cooling water, and the hot water inlet is connected to the water outlet of the online heating device 5 for online heating of the return water flowing out from the water outlet of the shaft roller 4, so The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com