Processing method of samarium cobalt magnetic steel

A processing method and technology of magnetic steel, which are applied in the manufacturing of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of falling corners, low processing efficiency, and poor processing accuracy of fast wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

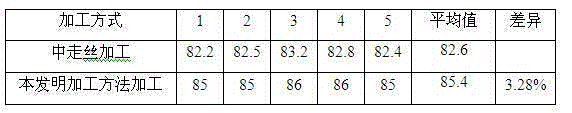

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) The sintered samarium cobalt blank with qualified magnetic properties is 57mm×45mm×48mm square, and processed into a Φ10.5mm×57mm cylinder by wire electric discharge cutting;

[0020] (2) Use a centerless grinder to polish the outer circle of the cylinder into a Φ10mm×57mm cylinder;

[0021] (3) Bond the Φ10mm×57mm cylinder to the glass plate with 502 magnetic material glue, 8 in each row, and 3 rows in total;

[0022] (4) Fix the glass plate bonded with the cylinder to the magnetic chuck, and then fix the magnetic chuck to the workbench of the multi-wire cutting machine. The direction of the center line of the cylinder is perpendicular to the winding direction of the multi-wire cutting machine;

[0023] (5) Use a multi-wire cutting machine to cut the cylinder into a thickness of 0.7mm. When using a multi-wire cutting machine to slice, the processing line uses Φ0.18mm steel wire;

[0024] (6) After the cutting is completed, take out the product, heat and boil it wi...

Embodiment 2

[0028] (1) Process the 57mm×45mm×48mm square of the sintered samarium cobalt blank with qualified magnetic properties into a 57mm×10mm×10mm square bar by using an inner circle slicer;

[0029] (2) Bond the square strips to the glass plate with 502 magnetic material glue, 8 pieces in each row, and 3 rows in total;

[0030] (3) Fix the glass plate bonded with square bars to the magnetic chuck, and then fix the magnetic chuck to the workbench of the multi-wire cutting machine. The direction of the center line of the square bar is perpendicular to the winding direction of the multi-wire cutting machine;

[0031] (4) Use a multi-wire cutting machine to cut the square bar into a thickness of 1.8mm. When using a multi-wire cutting machine to slice, the processing line uses Φ0.15mm steel wire;

[0032] (5) After the cutting is completed, take out the product, heat and boil with lye for 30 minutes, remove the product from the lye, clean and dry;

[0033] (6) Inspection of size and app...

Embodiment 3

[0036] (1) The sintered samarium cobalt blank with qualified magnetic properties is 57mm×45mm×48mm square, and is processed into a Φ10mm×Φ5mm×57mm ring strip by a hole-setting machine;

[0037] (2) Bond the ring strips to the glass plate with 502 magnetic material glue, 8 pieces in each row, and 3 rows in total;

[0038] (3) Fix the glass plate bonded with the strips of the ring to the magnetic chuck, and then fix the magnetic chuck to the workbench of the multi-wire cutting machine. vertical;

[0039] (4) Use a multi-wire cutting machine to cut the ring strip into a thickness of 1.5mm. When using a multi-wire cutting machine to slice, the processing line uses Φ0.2mm steel wire;

[0040] (5) After the cutting is completed, take out the product, heat and boil with lye for 40 minutes, remove the product from the lye, clean and dry;

[0041] (6) Inspection of size and appearance, the pass rate reached 94%;

[0042] (7) Clean the countertop, switch the magnetic chuck to a non-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com