Multi-wire saw and method of cutting ingot

A wire saw and billet technology, which is applied in the field of multi-wire saw and billet cutting, can solve the problems of shallow guide grooves, broken wires, defects, etc., and achieve the effect of reducing plate thickness deviation and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

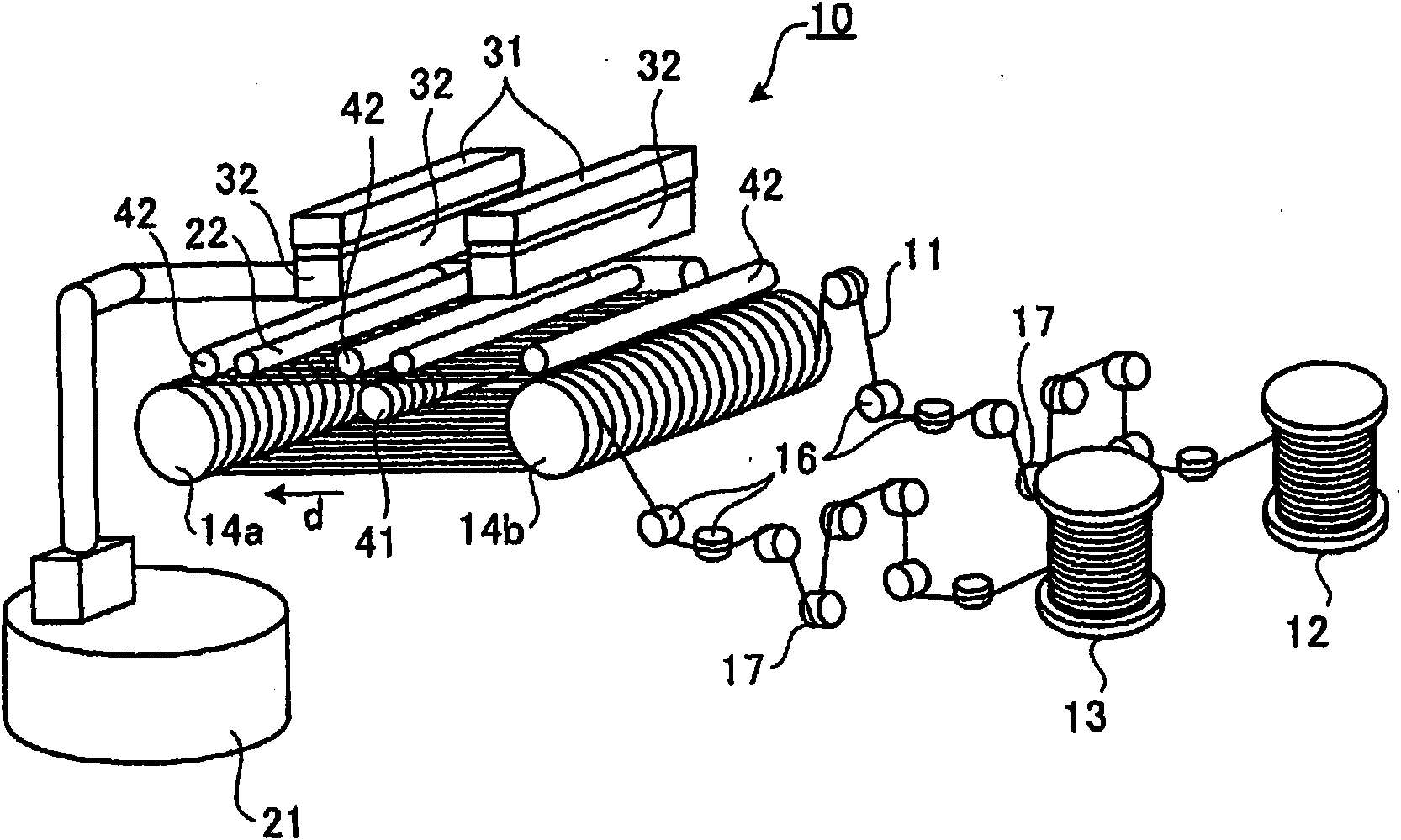

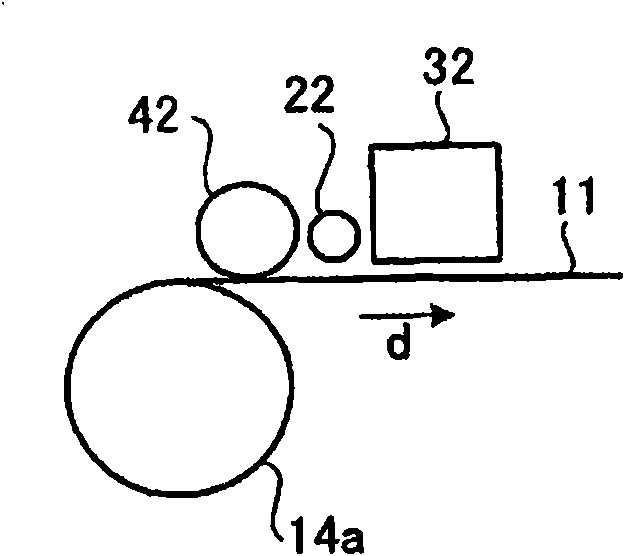

[0031] figure 1 It is a perspective view showing the structure of the main part of the multi-wire saw of the present invention, figure 2 It is a side view of the structure near the wire guide roller viewed from the direction of the wire guide roller rotation axis, image 3 It is a figure which schematically shows the relationship of a wire regulation part and a wire guide roller.

[0032] Such as figure 1 As shown, the multi-wire saw 10 has: a wire 11; a wire sending mechanism 12 for sending out the wire 11; a wire winding mechanism 13 for winding the sent wire 11; Between the two wire guide rollers 14a, 14b arranged in a manner that the rotation axes are parallel to each other; between the wire feeding mechanism 12 to the wire guide roller 14a and from the wire guide roller 14b to the wire winding mechanism 13 a plurality of guide rollers 16 that each guide the wire 11 to travel; and a tension roller 17 that controls the tension of the wire 11 guided by the guide rollers ...

Embodiment approach 2

[0041] Figure 4 It is a block diagram showing the functional configuration of the control unit of the multi-wire saw according to the present invention. This control unit 50 has a wire deflection profile calculation unit 51 and a processing control unit 52 . In addition, the configuration of the multi-wire saw 10 controlled by the control unit 50 is the same as that in the first embodiment. figure 1 The shown configurations are the same, so descriptions thereof will be omitted.

[0042] The wire deflection profile calculation unit 51 derives the deflection of the wire 11 at a predetermined cutting position when the depth of the cutting groove formed when cutting the blank 32 is started is at least equal to or deeper than the radius of the wire 11 . Figure 5 It is a cross-sectional view schematically showing the state in which the blank is cut to a depth e when the blank is started to be cut, Figure 6 It is a diagram schematically showing the state of the multi-wire saw v...

Embodiment approach 3

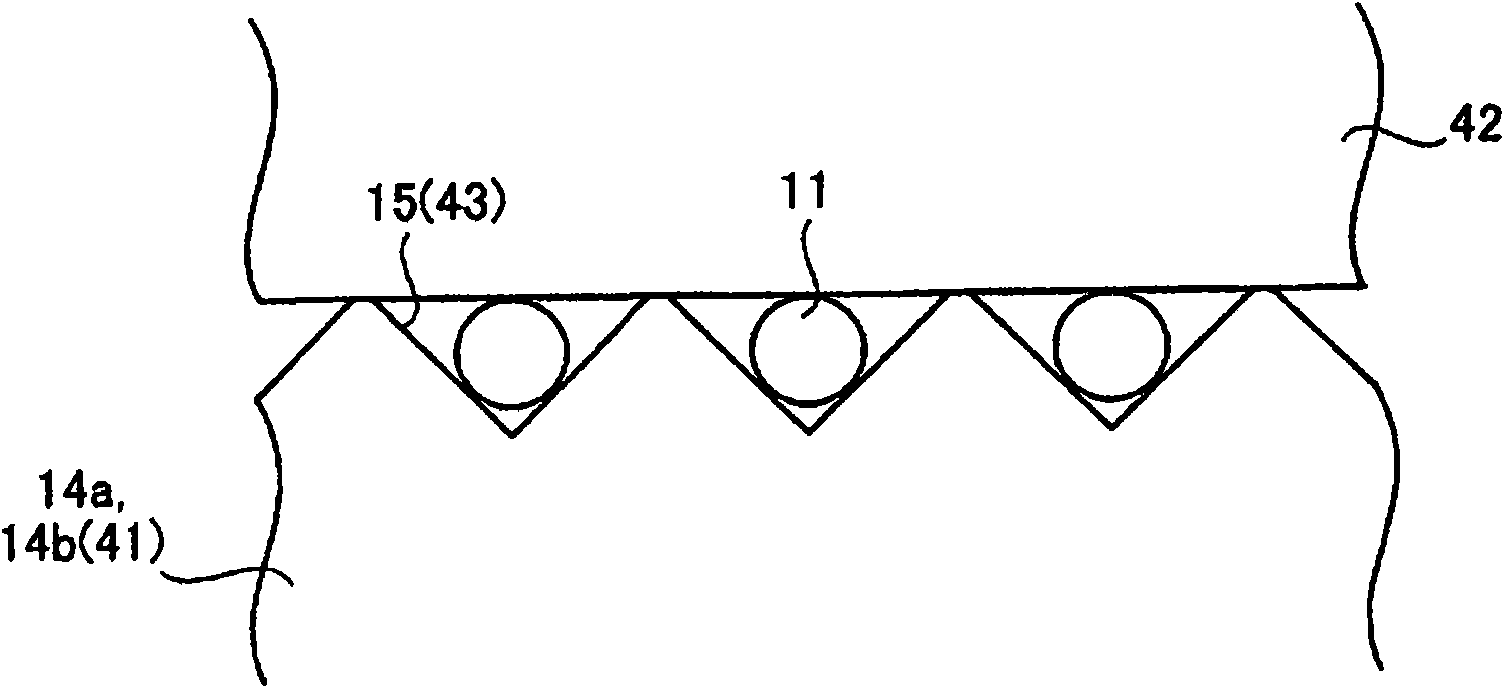

[0052] In the above-mentioned Embodiments 1 and 2, the wire lifting restricting member 42 that prevents the wire 11 from floating can also be made into a cylindrical shape of revolution, that is, it is provided on the cylindrical surface and formed on the wire. The guide grooves 15, 43 of the guide rollers 14a, 14b, 41 are equally spaced grooves.

[0053] According to this Embodiment 3, by forming the guide groove on the surface of the wire lifting restricting member 42, compared with the case of the cylindrical revolving body which is not formed at all, it is possible to further suppress the lateral movement of the wire at the moment of cutting start. Pendulum, the effect of further reducing the plate thickness deviation at the edge of the wafer.

[0054] Hereinafter, effects when cutting a material with the multi-wire saw 10 according to Embodiments 1 to 3 described above will be described. Cutting experiments were performed three times each using the multi-wire saw 10 havi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com