Magnetic-field-aided multi-wire-saw cutting machine

A saw cutting machine and magnetic field assisted technology, applied in the field of magnetic field assisted multi-wire saw cutting machine and multi-wire saw cutting machine, can solve the problems of small increase of cutting force, limited magnetic force effect, inconvenient installation and position adjustment of magnetic force source, etc. , to increase the cutting force and avoid wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

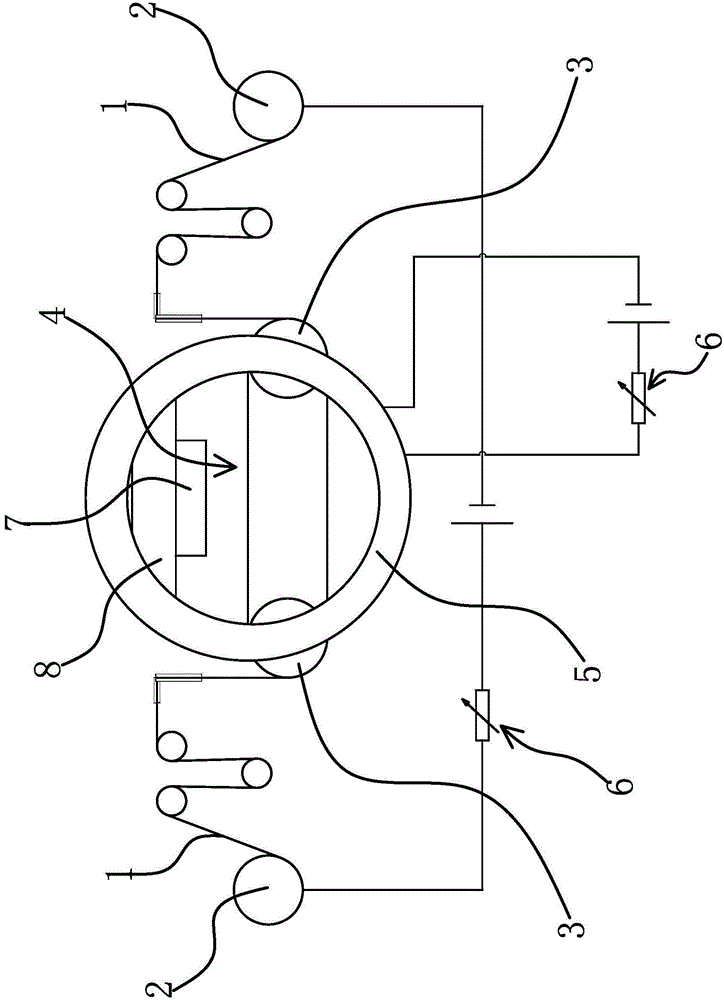

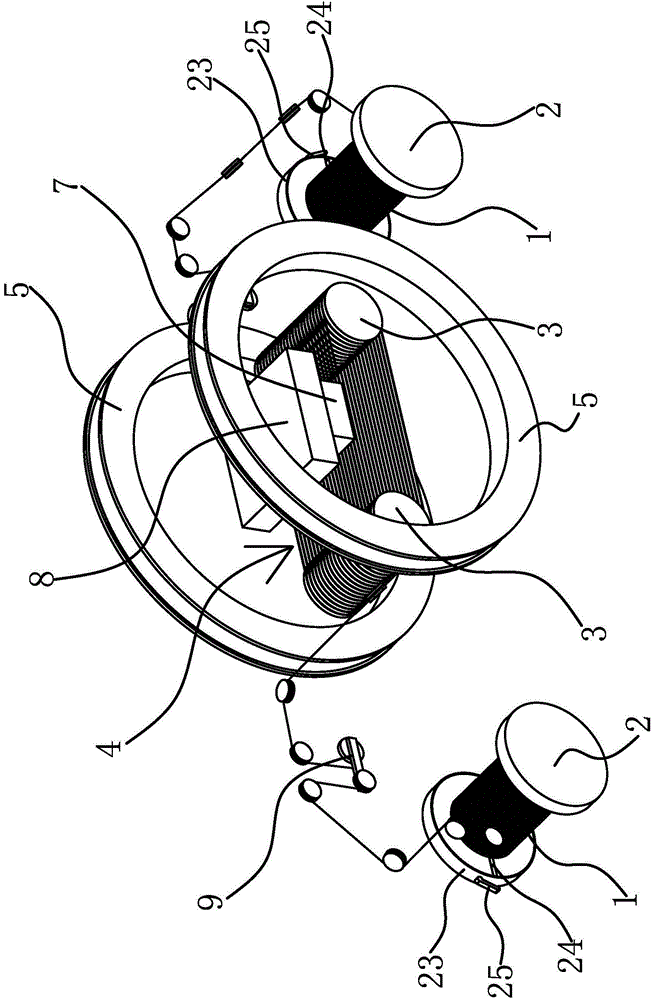

[0030] The multi-wire saw cutting machine includes a wire saw 1, two wire storage wheels 2 and several guide wheels 3. The two ends of the wire saw 1 are respectively wound on the wire storage wheels 2, and the wire storage wheels 2 are rotated so that one end of the wire saw 1 is retracted. The other end of the wire is laid out, and the wire saw 1 is laid on the guide wheel 3 to form a cutting part 4 composed of a plurality of parallel wire saws 1. The wire saw 1 on the cutting part 4 moves in one direction or reciprocates to cut the workpiece 7 to be processed. The multi-wire saw cutting machine assisted by the magnetic field also includes a power supply device and a magnetic field generating device.

[0031] Specifically, as figure 1 As shown, the two ends of the wire saw 1 are respectively connected to the positive and negative poles of the power supply device, so that the current direction on the cutting part 4 is the same. The magnetic field generating device is located...

Embodiment 2

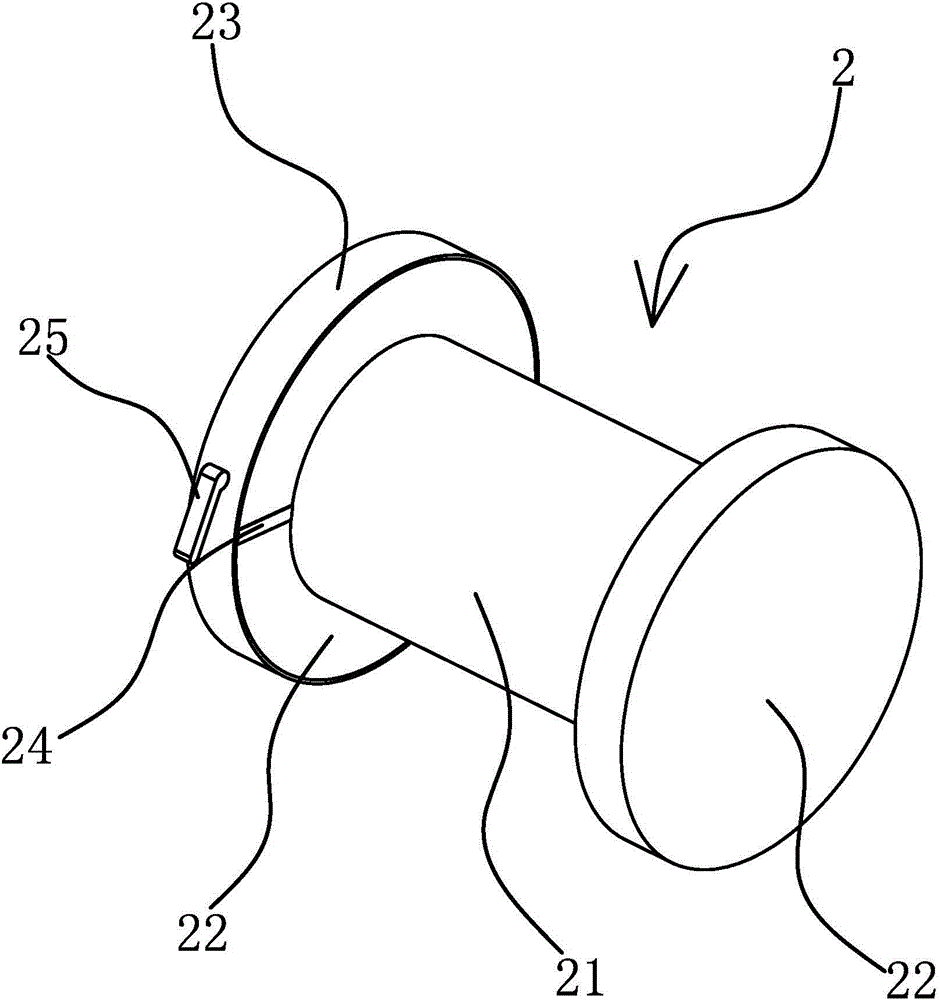

[0036] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as Figure 4 As shown, in this embodiment, the storage part 21 of the storage wheel 2 also has a conductive strip 24, and the conductive strip 24 directly passes the current to the wire saw 1 located in the storage part 21, so that the contact in the circuit is better.

Embodiment 3

[0038] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the center lines of the two coils 5 are located on the same straight line, and the positions of the coils 5 are fixed. The magnitude of the current controls the strength of the magnetic field. As a preferred solution, the radius and the number of turns of the two coils 5 are the same, and the distance between the two coils 5 is equal to half the diameter of the coils 5. In the multi-wire saw cutting machine, affected by the width of the cutting part 4, the distance between the two coils 5 The distance is difficult to get very close, the magnetic field strength of the cutting part 4 is small, and the current in the wire saw 1 cannot reach a high value. Therefore, in the process of actually using magnetic field-assisted cutting, the effect is often not ideal. It is found through repeated tests that when the two coils 5 meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com