Eggshell peeling machine

A peeling machine and eggshell technology, applied in the direction of food science, etc., can solve the problems of time-consuming, labor-intensive, time-consuming and labor-intensive, and achieve the effect of preventing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

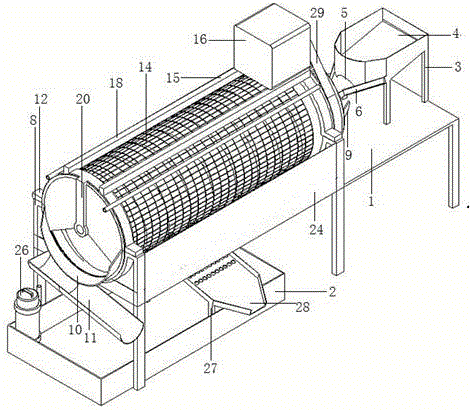

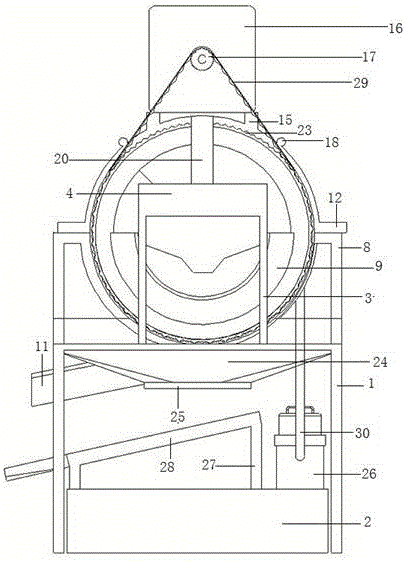

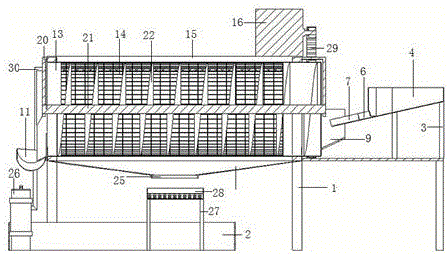

[0022] Specific implementation mode one: combine Figure 1-5 As shown, a kind of egg shell peeling machine comprises workbench 1 and water tank 2; One side of the upper end of workbench 1 is fixedly connected with feeding box bracket 3; The upper end of feeding box bracket 3 is welded with feeding box 4; One side is welded with a cage support 8; one side of the cage support 8 is connected with an egg inlet 9 by screws; the other side of the cage support 8 is connected with an egg outlet 10 by screws; the lower end of the egg outlet 10 is welded with an egg outlet 11. Cage bracket 8 is connected with clamp 12 by screws; cage bracket 8 is fixedly connected with the middle part of clamp 12 with copper sleeve 13; inside copper sleeve 13 is set with cage 14; the top of clamp 12 is connected with motor bracket by screws 15; the motor bracket 15 is fixedly connected with a motor 16; the shaft end of the motor 16 is fixedly connected with an active synchronous pulley 17; the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com