Preparation method of composite ceramic

A composite ceramic and ceramic technology, applied in the field of ceramics, can solve the problems of high brittleness and heavy structure, and achieve the effect of enhancing the bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Take methanol and soft water with a mass ratio of 1:1 (industrial softened water obtained by ion exchange method, the hardness meets the GB1576-2008 "Industrial Boiler Water Quality" standard, less than 0.03mmol / L), add acetic acid to adjust the pH value = 5, select γ- Glycidyl ether oxypropyltrimethoxysilane coupling agent is prepared into a clear solution with a mass concentration of silane coupling agent of 0.5%; select a square aluminum oxide ceramic block with a side length of 50 mm, 6.5 mm thick, and put it into the above solution Soak in medium for 30 seconds and take out for use.

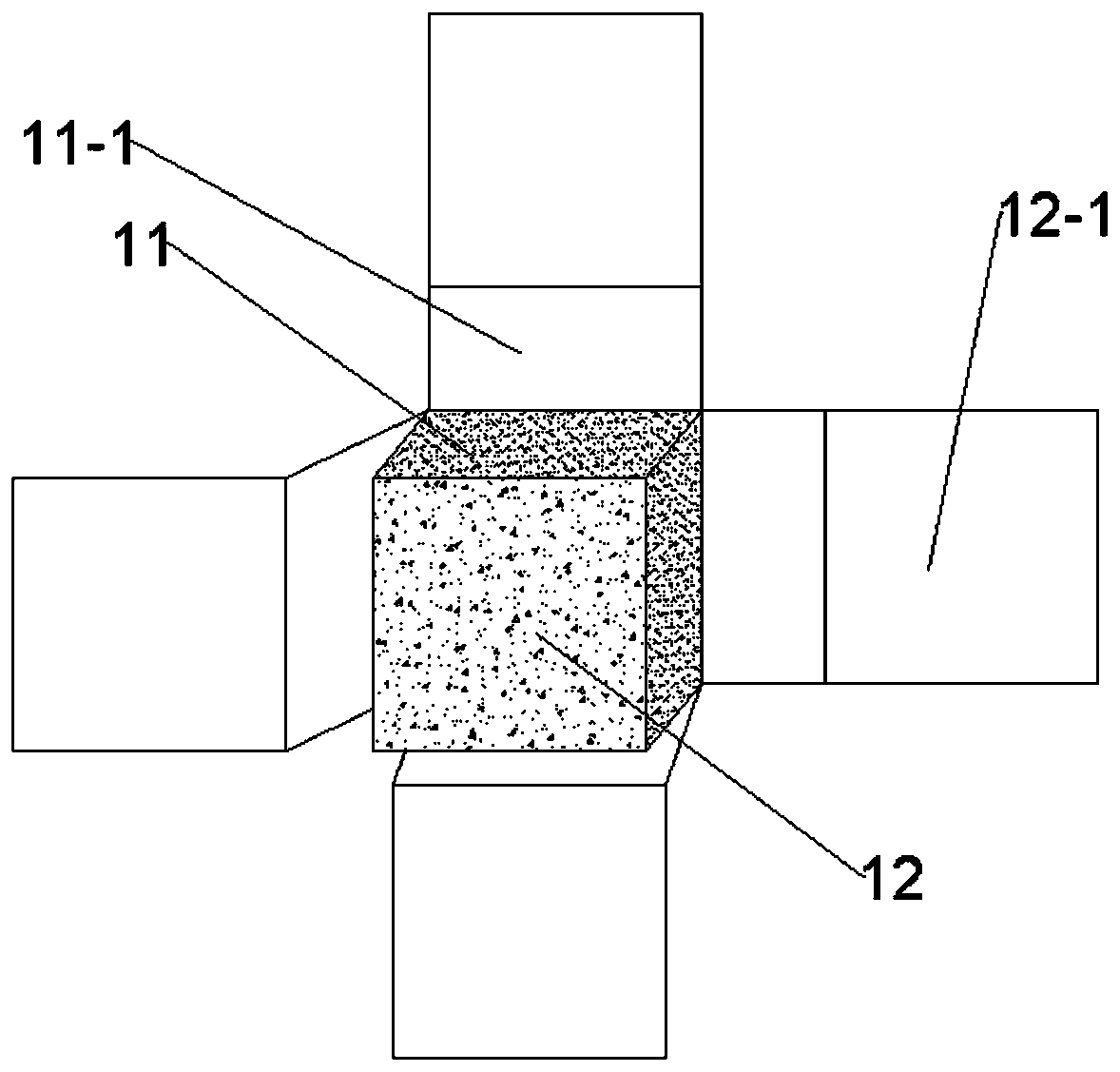

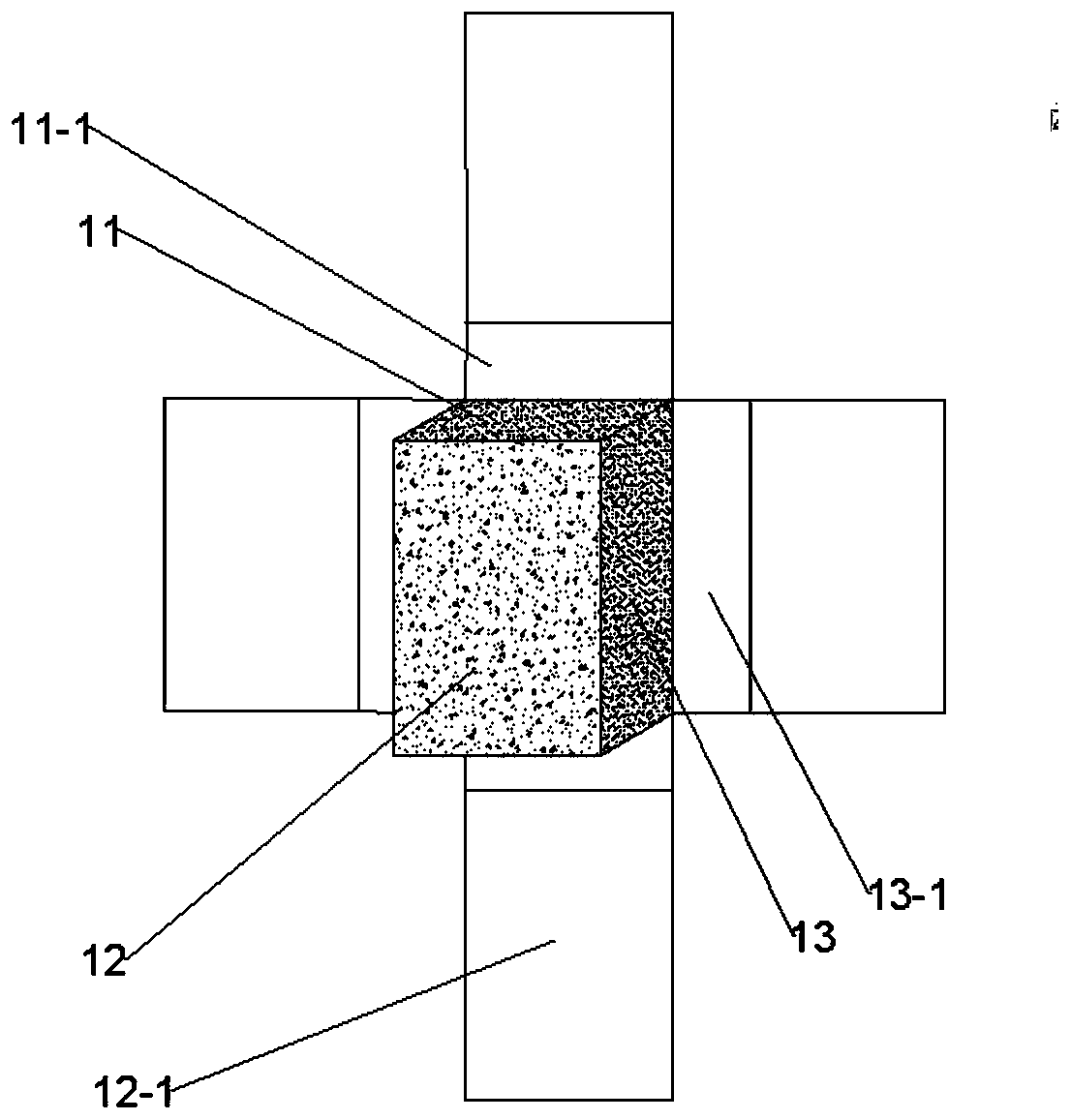

[0090] Use 0.2mm thick plain aramid fiber cloth fabric, first design the plain aramid fabric cutting drawing, according to figure 2 As shown in the design, the center of the cross-shaped plain aramid fiber fabric is a 50mm square, and the four branches are a rectangle of 50mm×56.5mm. The plain aramid fiber fabric is cut into the above shape on a computer-aided laser cutting machine. ...

Embodiment 2

[0098] Select a square boron carbide ceramic block with a thickness of 13 mm and a side length of 50 mm for pretreatment according to the method in Example 1 for use.

[0099] Use 0.2mm thick plain weave glass fiber cloth to encapsulate small ceramic pieces, first design the cutting drawing of plain weave glass fiber cloth, follow figure 2 As shown, the center of the cross-shaped plain glass fiber cloth is a 50mm square, and the four branches are a 50mm×63mm rectangle, and the glass fiber cloth is cut on a computer-aided laser cutting machine.

[0100] Use the above cut plain fiberglass cloth according to figure 2 As shown, the above-mentioned treated small ceramic block is wrapped to obtain an encapsulated small ceramic block.

[0101] Cut the appearance size of the armor and the thickness is 0.2mm Three pieces of glass fiber cloth, one of which is made of epoxy resin (An Debao brand HJ-3-1 epoxy resin product provided by Shanghai Huayi Resin Co., Ltd.) Hand-coated and bo...

Embodiment 3

[0107] The composite ceramics after the test in Example 2 is removed, and the boron carbide ceramic fritters with a thickness of 13mm are filled after cleaning up, and the replacement thickness of a new UHMWPE laminate is 20mm, such as Figure 5 Shown, then prepare composite ceramics according to the method in embodiment 2.

[0108] According to the "GA950-2011 Bulletproof Materials and Products V50 Test Method" standard, the Type 54 12.7mm armor-piercing incendiary bomb was used to test, and its V50 was 698.5m / s, which indicated that after the packaged ceramic plate was ballistically impacted, the impact point was removed. For damaged ceramics, the ceramics in other positions remain intact, with good performance, and have the value of secondary use.

[0109] As can be seen from the above examples, the present invention provides a method for preparing composite ceramics, comprising: bonding fiber cloth on the surface of the bulletproof backboard; bonding a plurality of package...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com