Polycrystalline silicon chip cutting method capable of saving steel wire

A cutting method and technology for polycrystalline silicon wafers, which are applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problem of high cost of cutting steel wires, save the amount of mortar, ensure processing efficiency, and facilitate chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

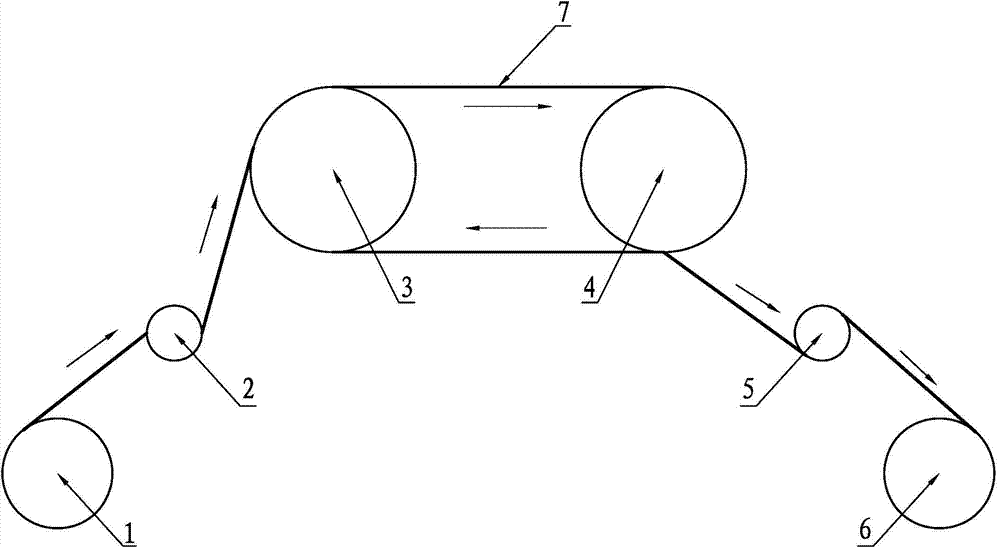

[0014] A polysilicon wafer cutting method that saves steel wires, such as figure 1 As shown, according to the prior art, the cutting steel wire 7 is released from the pay-off pulley 1, passes through the front pulley 2, enters the wire from the incoming wire guide pulley 3, and exits the wire from the outgoing wire guide pulley 4, and then passes through the rear pulley 5 and is wound on the take-up pulley 6. Above, the electrical control system controls the steel wire transmission mechanism including the pay-off wheel 1, the wire-in guide wheel 3, the wire-out guide wheel 4 and the wire-take-up wheel 6 to drive the cutting steel wire 7 between the wire-in guide wheel 3 and the wire-out guide wheel 4. The high-speed forward and reverse intervals alternately move in a straight line. The high-speed moving cutting steel wire 7 carries the silicon carbide in the mortar to cut the polysilicon ingot. The direction of rotation of the outgoing guide wheel 4 and the take-up wheel 6; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com