Greenhouse gas discharging-reducing and commercialized utilization method

A greenhouse gas, cavity technology, used in lighting and heating equipment, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

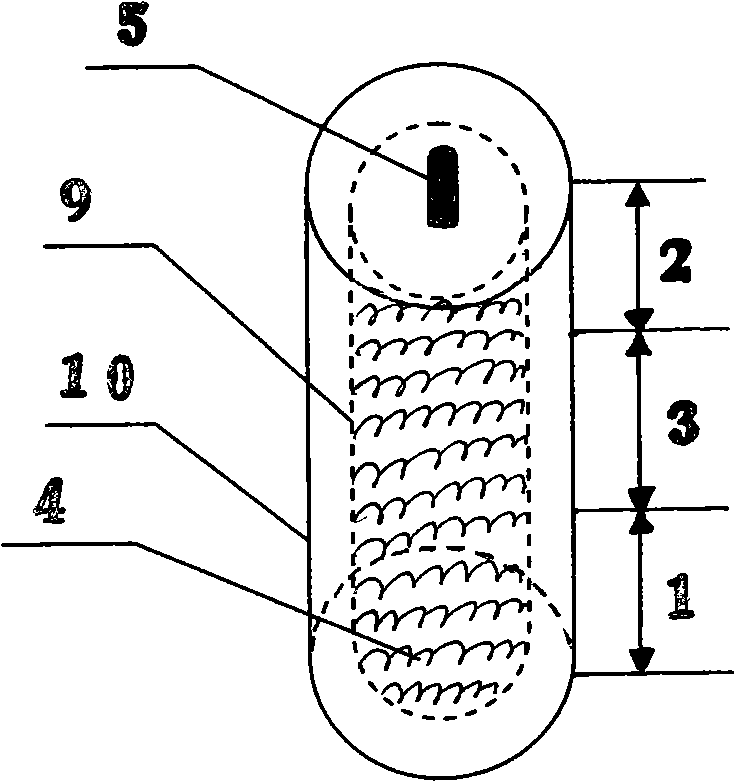

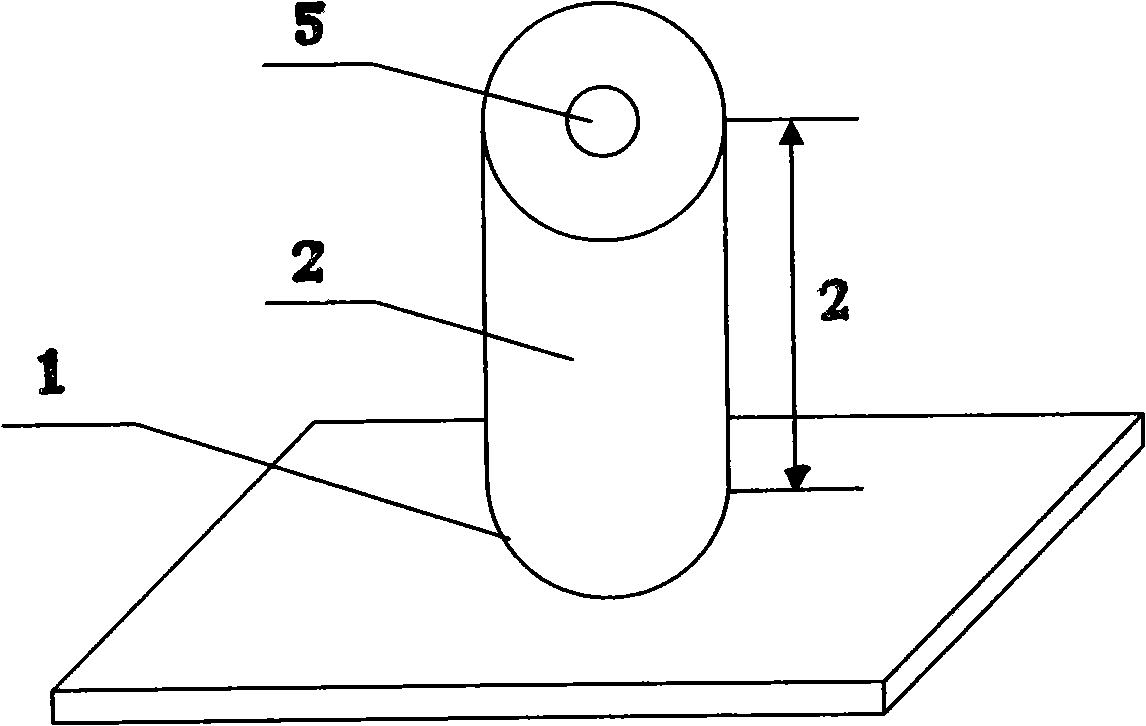

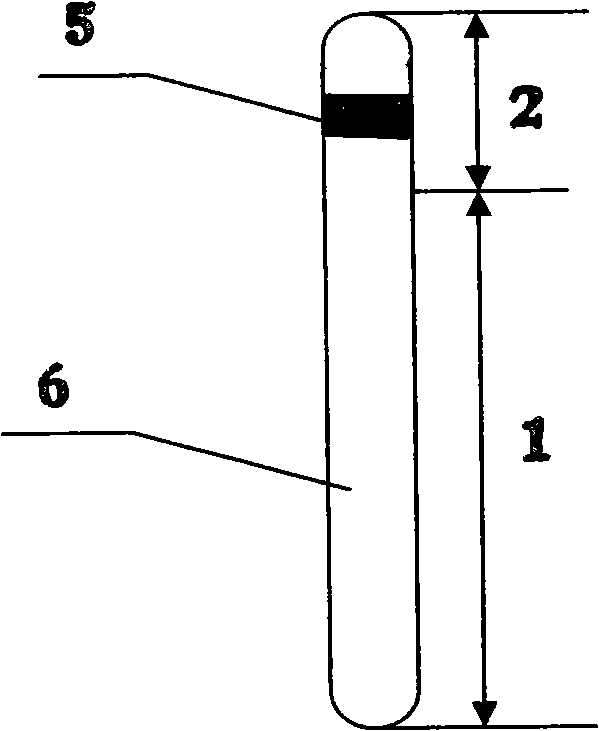

[0071] Basic Multiphase Heat Transfer Elements

[0072] Please refer to figure 1 , a carbon steel pipe with a diameter of 38MM and a length of 1M. The upper and lower ends of the pipe are sealed to form a cavity. Aluminum, whose thickness is thicker than the rare earth aluminum inside, is mainly used for anti-corrosion and heat conduction, and aluminum has higher heat conduction performance than carbon steel; inside the cavity, on a sealing surface of the tube, a one-way valve is processed, Use a one-way valve to fill the carbon dioxide gas into the cavity, and the weight of the filling is 300 grams. The solids are: 10 grams of copper with a particle size of 0.001mm, and 3 grams of copper oxide with a particle size of 0.01mm. 100 grams of aluminum with a particle size of 0.3 mm. This constitutes the basic multiphase heat conducting element. Working temperature range: 10-130°C, working pressure range: 1-15MPa. When the working temperature is 31 degrees and the pressure is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com