Active back-blowing cleaning equipment for selective laser melting manufacturing

A technology of laser selective melting and cleaning equipment, applied in the field of additive manufacturing, can solve the problems of increasing manufacturing cost, affecting molding effect, and unable to ensure continuous operation of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

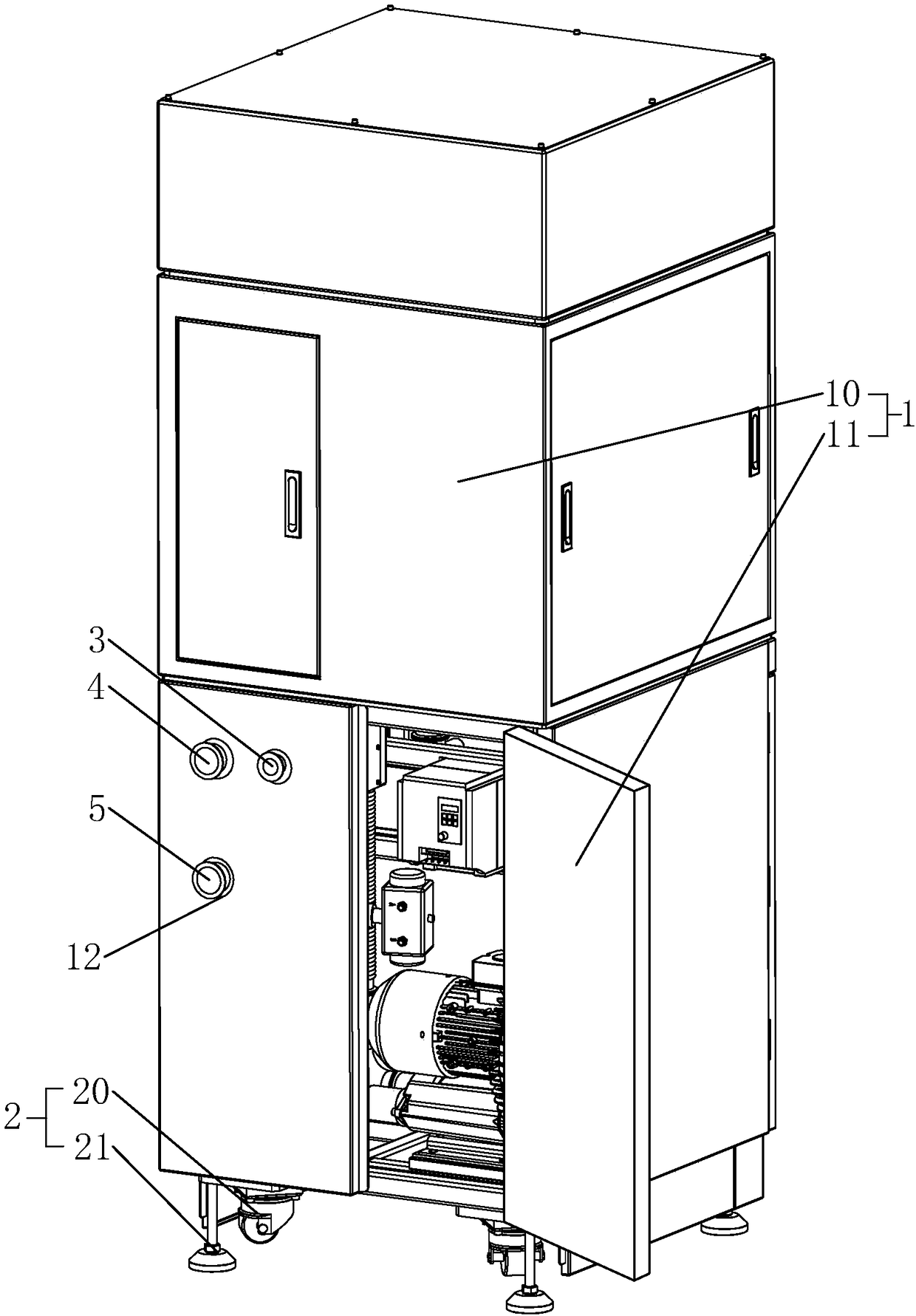

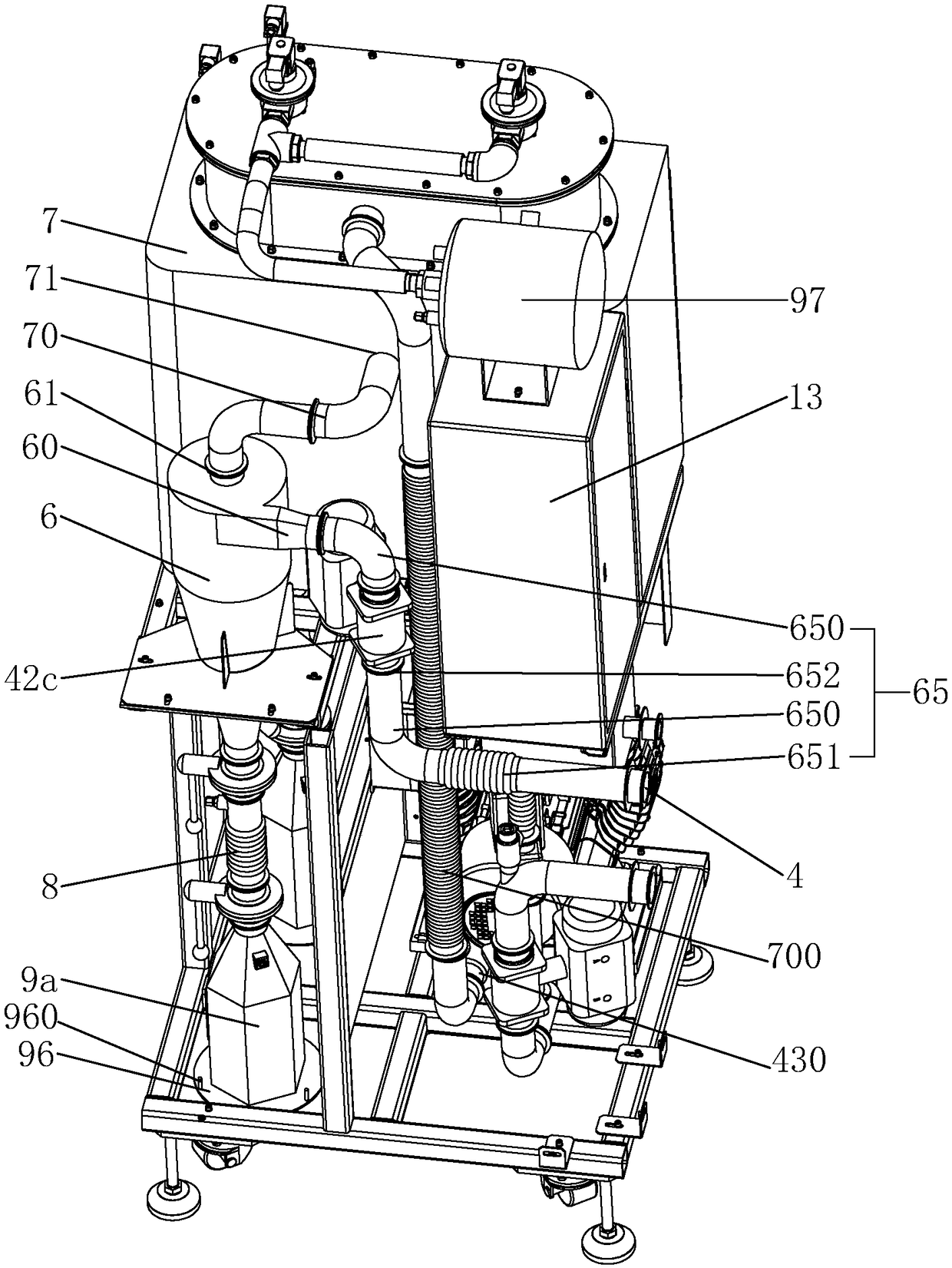

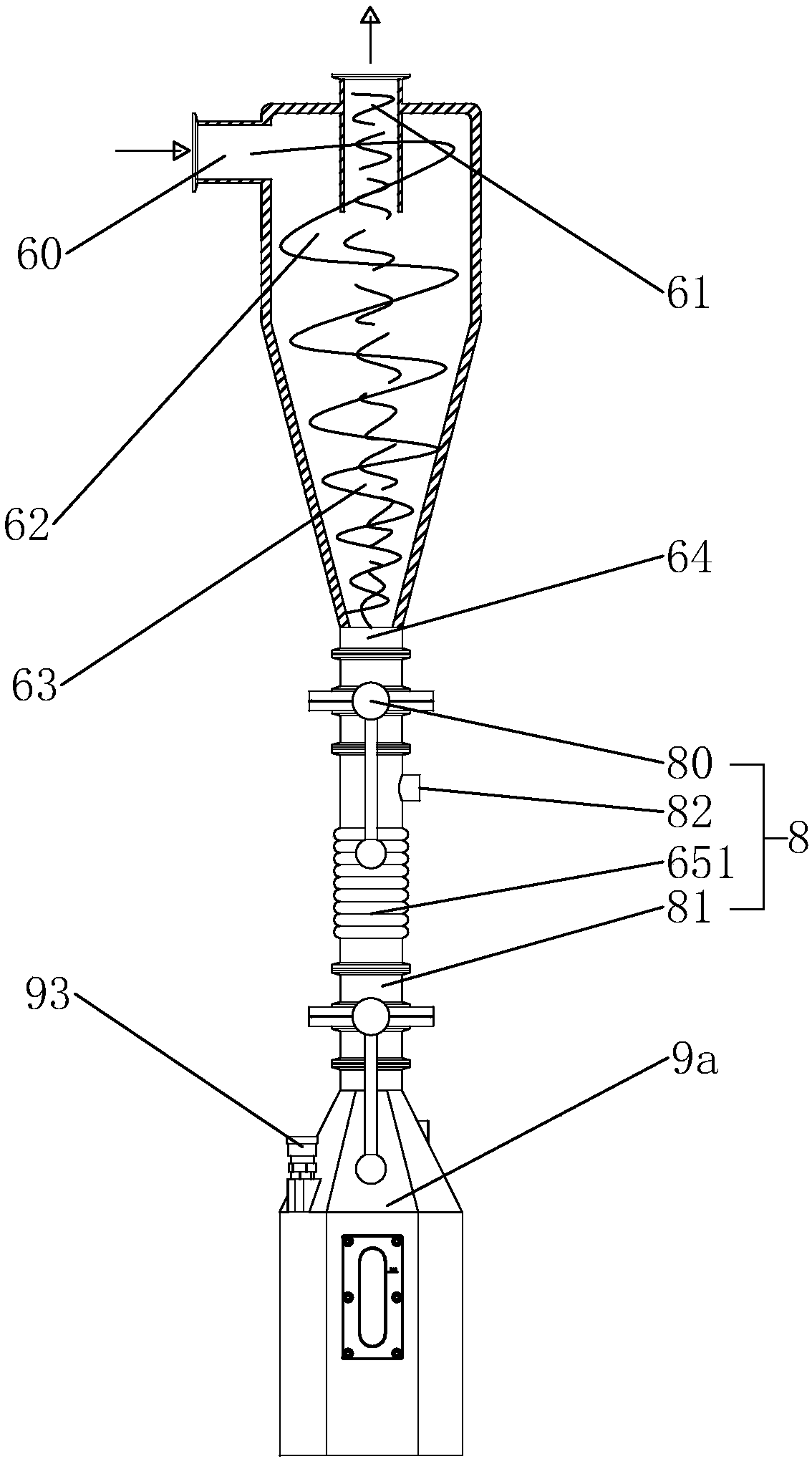

[0040] An active backflush cleaning device for selective laser melting manufacturing, such as figure 1 As shown, it includes a cabinet body 1 and a support mechanism 2 supporting the cabinet body 1 .

[0041] The support mechanism 2 includes adjustable foot cups 20 and casters 21. Four adjustable foot cups 20 are respectively installed at the apex of the lower surface of the cabinet body 1, and four casters 21 are respectively installed on the insides of the four adjustable foot cups 20. . Slide the active backflush cleaning equipment to the corresponding SLM equipment through the casters 21, adjust the height of the adjustable foot cup 20, and fix the active backflush cleaning equipment horizontally on the ground. The casters 21 are used in conjunction with the adjustable foot cups 20. When it is necessary to move the gas circulation purification continuous operation equipment used for laser selective melting manufacturing, the adjustable foot cups 20 are lifted so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com