Method for preparing and purifying coal slag-zeolite composite purified ball and experimental device

A composite purification and experimental device technology, applied in chemical instruments and methods, separation methods, combustible gas purification, etc., can solve the problems of low ammonia nitrogen removal effect, reduction of effective surface area, single removal of pollutants, etc., and achieve economical and practical operating costs. , rich pores, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Cinder pretreatment: grind the cinder to 0.8mm with a pulverizer. Take 200g and put it into a 500mL jar, add 200mL of 7mol / L hydrochloric acid, -1 Shake it on a horizontal shaker for 10 hours, let it stand for 14 hours, pour off the supernatant, wash it repeatedly with water until the pH value is 6, and dry it.

[0035] 2) Zeolite pretreatment: wash the zeolite with clean water and grind it to 0.8mm.

[0036] 3) Preparation of PVA organic adhesive: Weigh 21.0g of polyvinyl alcohol, put it into 300mL of deionized water at 85°C, stir and dissolve, add 3.75g of succinic acid, stir evenly, and cool to room temperature to obtain PVA organic binder.

[0037] 4) Weigh 120g of cinder and 60g of zeolite after the above pretreatment, mix them evenly, put them into a ball forming machine, add PVA organic binder, and make a cinder-zeolite composite purification ball with a diameter of 3cm, dry at 60°C and put Soak it in clean water for 2 weeks, take it out and dry it again to...

Embodiment 2

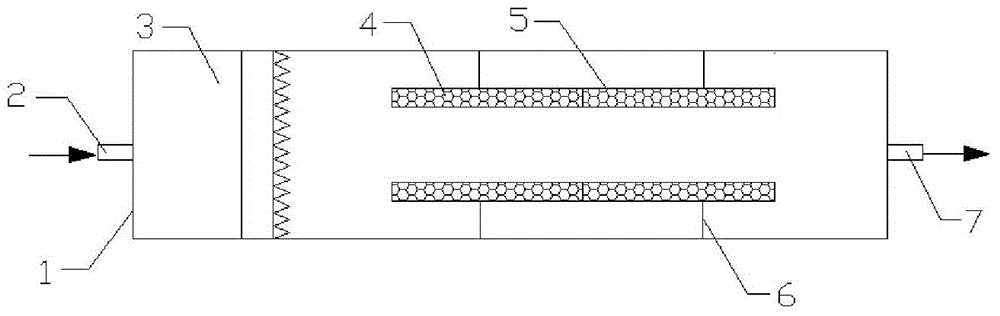

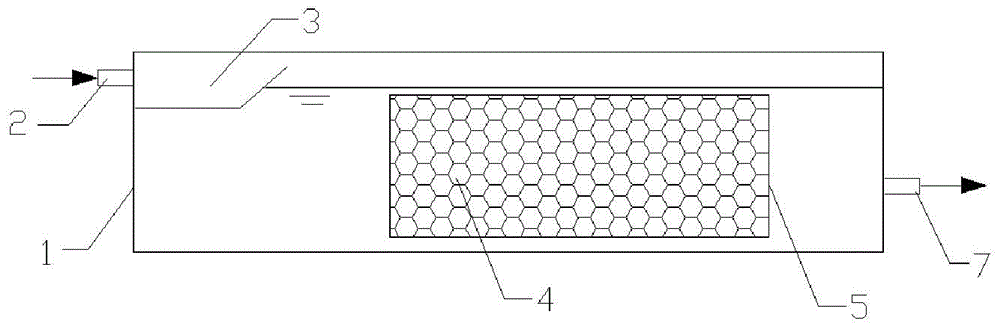

[0040] Such as figure 1 , 2 , the water tank purification experimental device of the present invention comprises the water inlet 2 and the water outlet 7 that the tank body 1 and its front and rear ends are provided with, and the water distribution weir 3 and the net cage 5 fixed on the support 6 are successively set in the tank body 1, wherein the net cage 5 The interior is filled with cinder-zeolite composite purification balls 5 .

[0041] The above-mentioned water distribution weir 3 is similar to a common cofferdam in water conservancy projects---a water distribution weir, and its purpose is to distribute water evenly along a predetermined channel in a predetermined area. The water distribution weir 3 of the present invention is a uniform water distribution board made of a plastic plate.

[0042] Above-mentioned net cage 6, support 7 are made of metal, as stainless steel wire, aluminum etc.;

[0043]The water body to be purified enters the tank body 1 through the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com