General modular circuit board structure

A general-purpose module and circuit board technology, applied in the direction of printed circuit components, printed circuits connected by non-printed electrical components, and electrical connection of printed components, etc., can solve the problems of wasting research and development resources, increasing development costs, and wasting resources. Achieve the effect of shortening the research and development cycle, reducing consumption costs and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

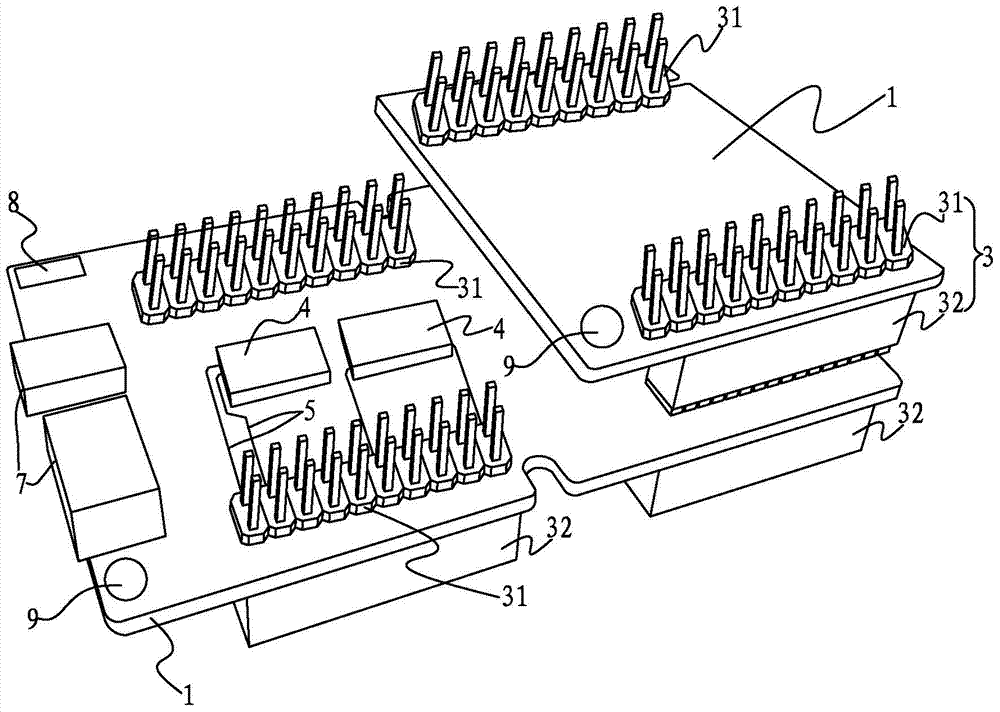

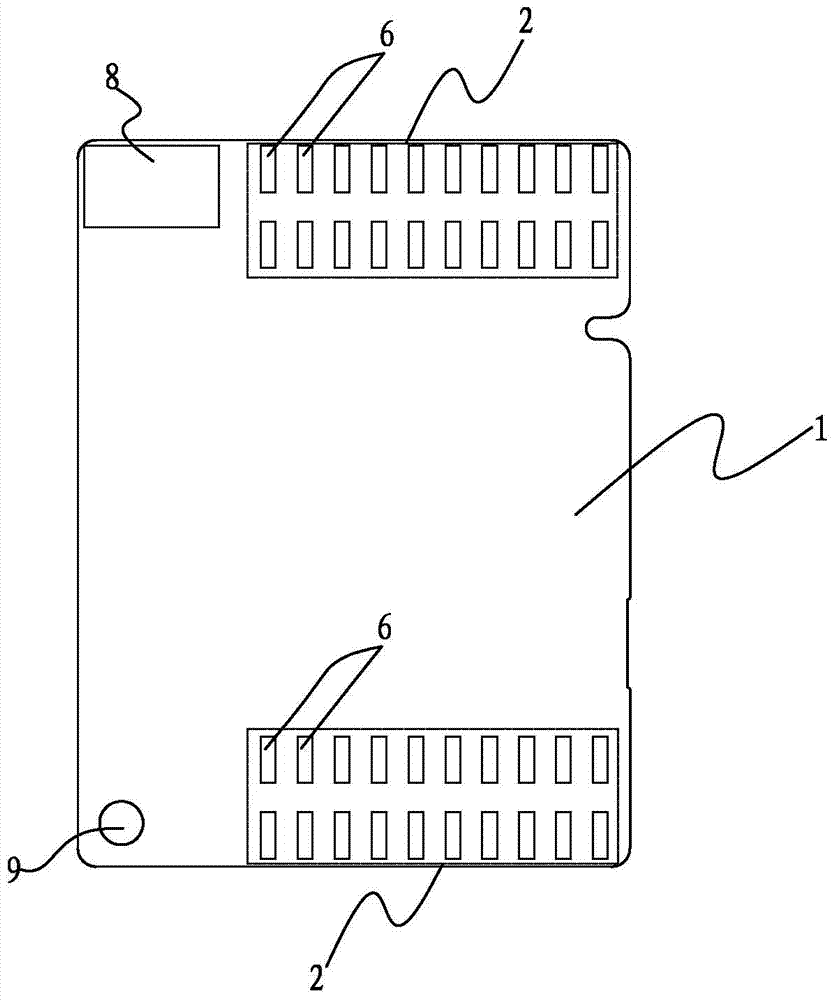

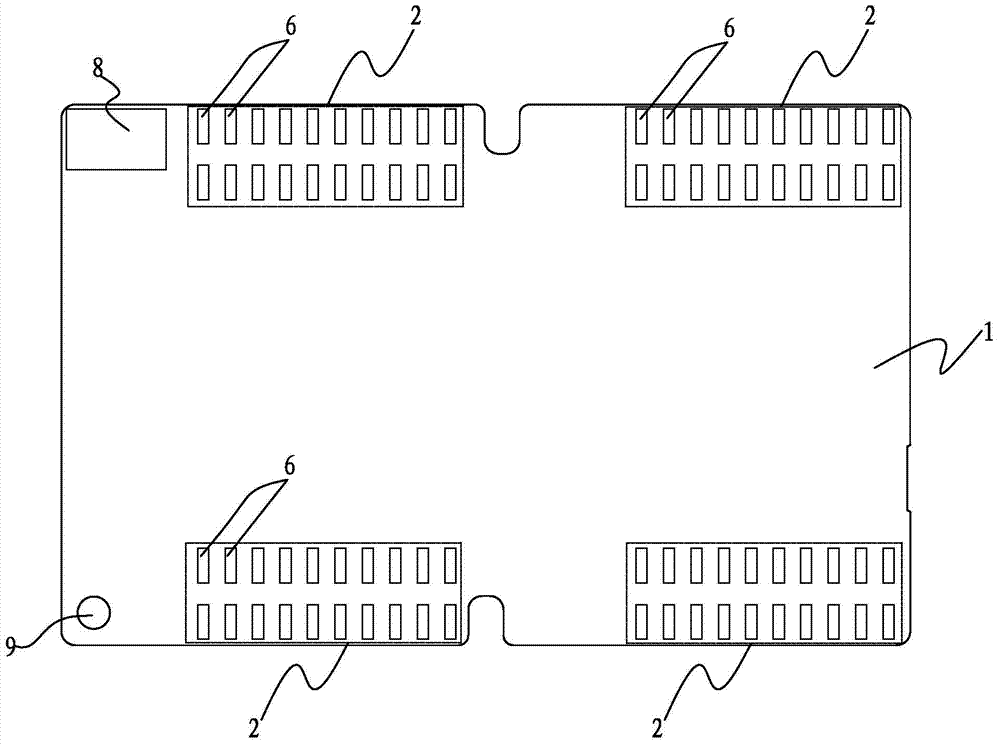

[0018] Such as figure 1 , figure 2 and image 3 A kind of general modularized circuit board structure shown is characterized in that, described circuit board structure comprises at least two interconnected circuit boards 1; Described circuit board 1 is arranged with a plurality of for carrying electric connector 3 Interface 2; the interface 2 is connected to the electronic component 4 arranged on the circuit board 1 through a conductive pattern 5; the interconnected circuit board 1 can pass through the interface 2 via the electrical connection carried on the interface 2 device 3 to transmit the functional signal set; on different circuit boards 1, the interfaces 2 corresponding to the same functional signal set have consistent interface pin definitions; further: on different circuit boards 1, the interfaces 2 corresponding to the same functional signal set are defined by The same number of interface pins 6 are formed, and the interface pins 6 corresponding to the same funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com