Double-temp-raising produced overcooling absorption and single effect, afterheat absorbing refrgerating system

A technology of temperature rise and subcooling, which is applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of small temperature difference between the inlet and outlet of heat source working fluid, low COP value, high initial investment, etc., and achieve compact equipment and absorption effect Enhanced, low heat source temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

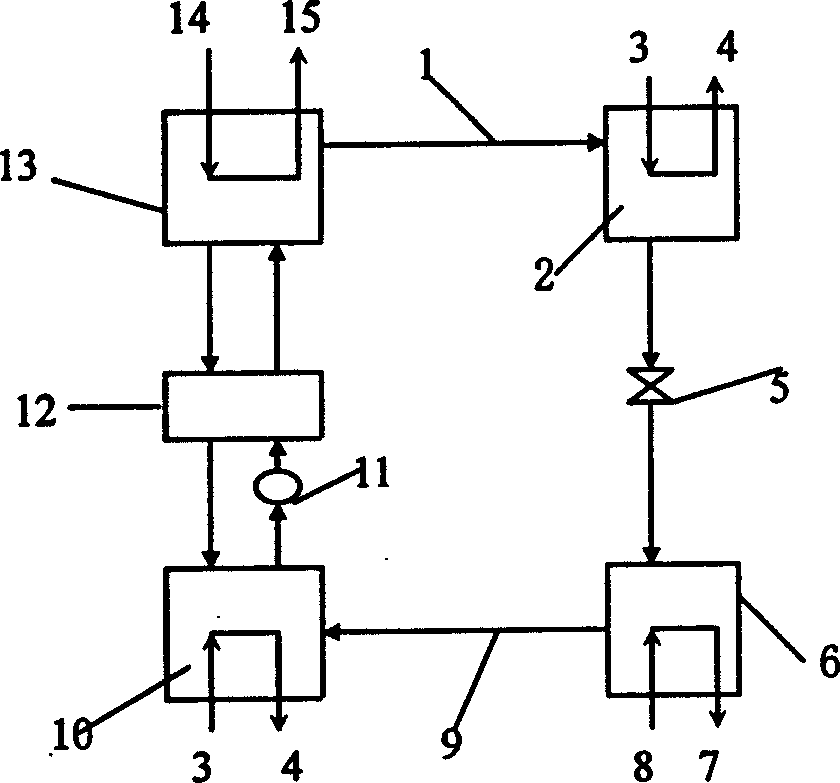

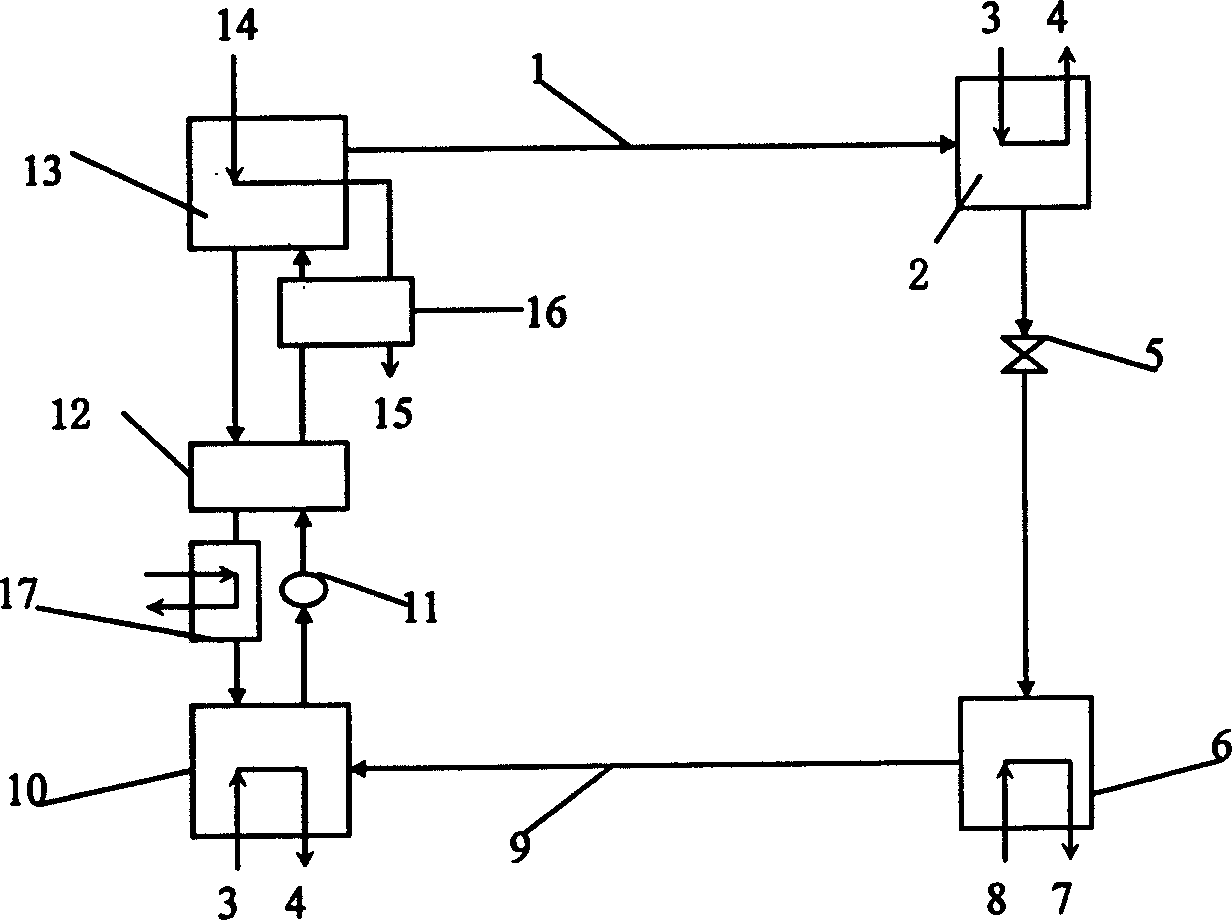

[0008] Depend on figure 1 and figure 2 As shown in the figure, the double temperature rise occurs in the supercooling absorption single-effect waste heat absorption refrigeration system. 5 enters the evaporator 6, in the evaporator 6, the refrigerant water is vaporized into low-pressure refrigerant water vapor, and at the same time absorbs the heat of the refrigerant water to produce a refrigeration effect, in the absorber 10 The concentrated lithium bromide solution from the solution heat exchanger 12 is used as the The absorbent absorbs the low-pressure refrigerant water vapor 5 from the evaporator 6. In order to increase the absorption capacity and take away the absorption heat released in the absorption process, the lithium bromide solution is cooled with cooling water, and the solution is diluted and then pumped into the solution with the solution pump 11. The heat exchanger 12 exchanges heat with the concentrated lithium bromide solution, and the dilute solution that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com