Reverse-flow solution desiccant fresh air handling unit driven by heat pump

A technology of heat pump drive and fresh air unit, applied in heating mode, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of complex structure, suboptimal thermal perfection, low heat and moisture exchange efficiency, etc. Achieve optimal system efficiency and reduce irreversible losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

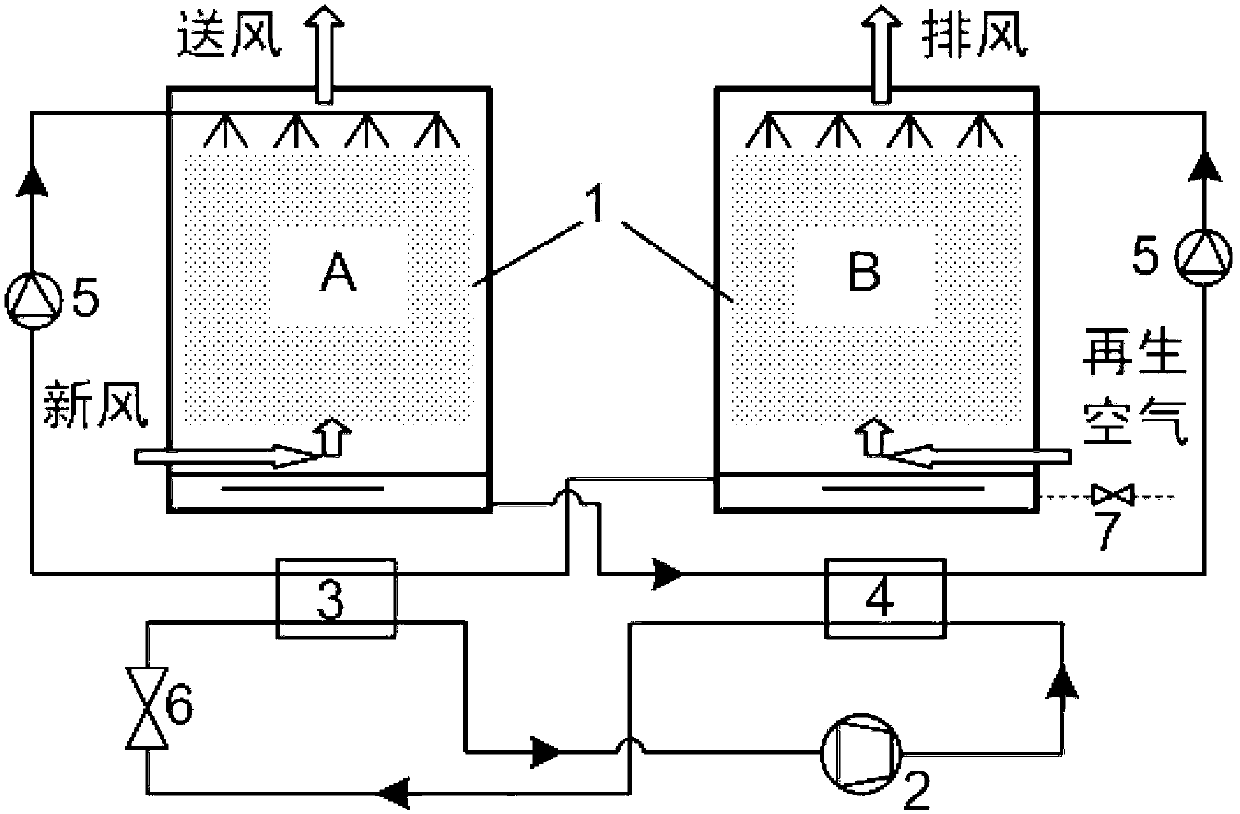

[0017] The purpose of the present invention is to provide a simple and efficient heat pump driven countercurrent solution humidity control fresh air unit. The heat and mass exchange between the solution and the air in the unit is in the form of countercurrent, and the evaporator and condenser of the heat pump are distributed in the solution circulation system. The lowest point and the highest point of temperature, in order to minimize the irreversible loss in the process of heat and mass exchange; the structure of the solution delivery pipeline of the unit is simple, which reduces the mixing loss between the dehumidification solution and the regeneration solution, and improves the overall effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com