Auxiliary heat dissipation device applied to refrigerator compressor

A refrigerator compressor, auxiliary cooling technology, applied in mechanical equipment, machinery/engine, liquid variable capacity machinery, etc., can solve the problem that the heat of the condensate cannot be discharged in time, it is not conducive to the normal function of the equipment, and the compression resistance of the compressor is increased. problems, to achieve the best heat dissipation effect, easy installation and maintenance, and reduce compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

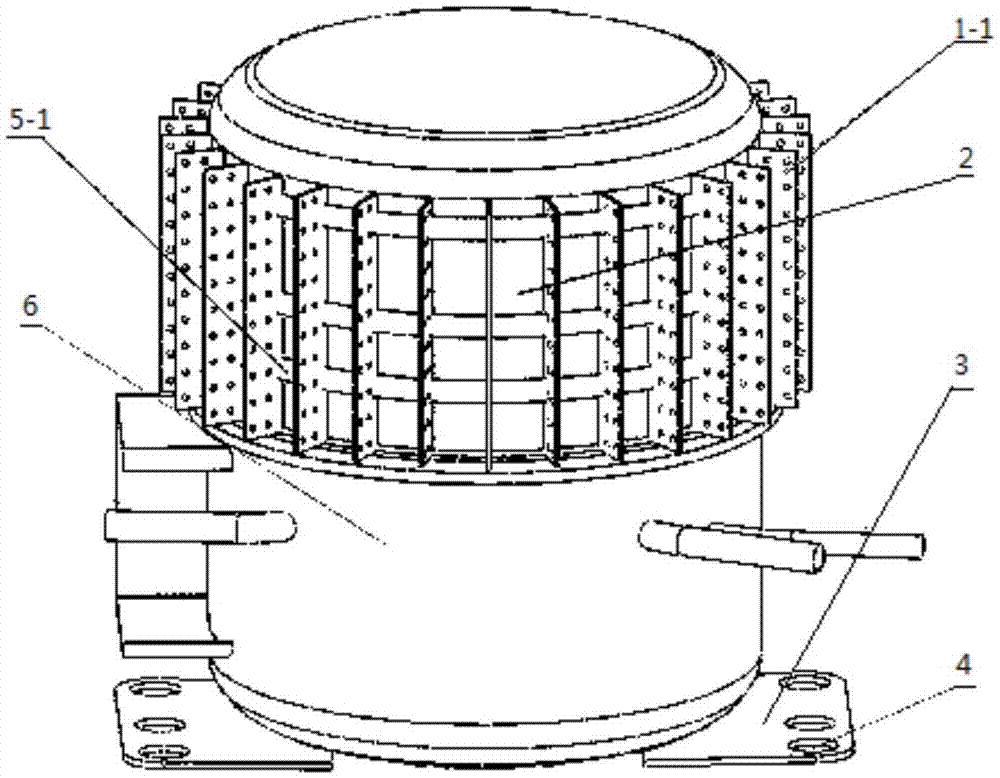

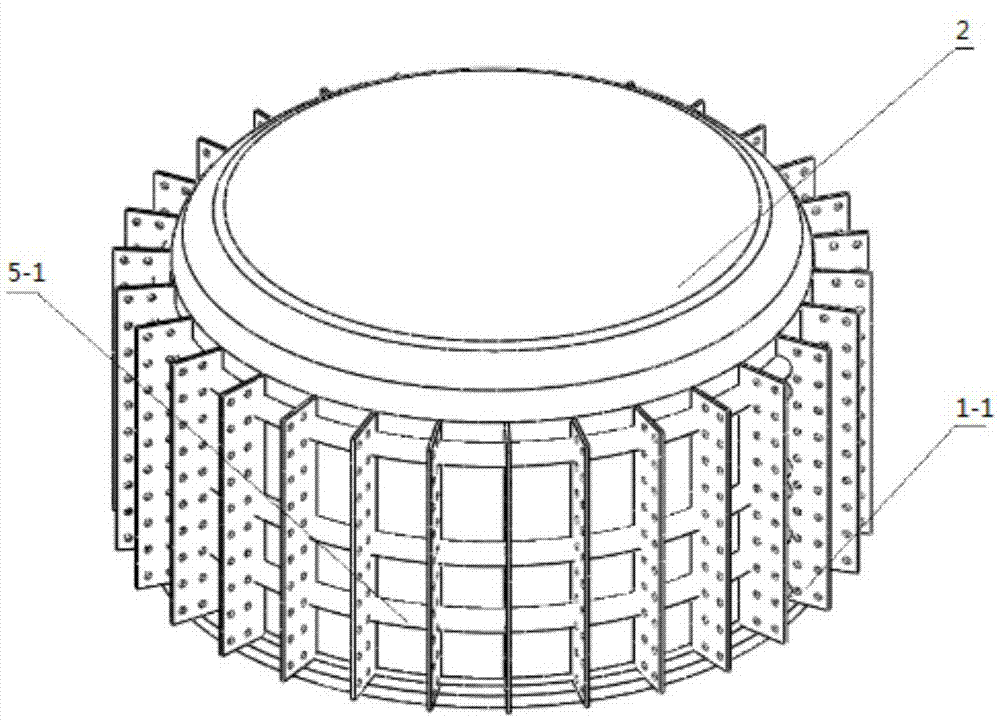

[0039] Such as figure 1 As shown, an auxiliary heat dissipation device applied to a refrigerator compressor is an auxiliary heat dissipation device for a compressor based on a heat pipe 5-1 and a cooling fin 1-1, and mainly includes a compressor upper casing 2, a compressor lower casing 6, Heat pipe 5-1, cooling fins 1-1; compressor upper casing 2 is in the shape of a cylindrical cover with a small arc surface at the top; compressor lower casing 6 is also in the shape of a cylindrical cover with a base 3 designed at the lower end, and There are four fixing bolt holes 4; the compressor upper shell 2 and the compressor lower shell 6 are connected to each other to form an airtight space, and assembled into the outer shell of the compressor to protect the internal components of the compressor. The heat pipes 5-1 are ring-shaped, and many of them surround the side of the upper casing of the compressor; the cooling fins 1-1 are embedded on the heat pipes 5-1, arranged vertically eve...

Embodiment 2

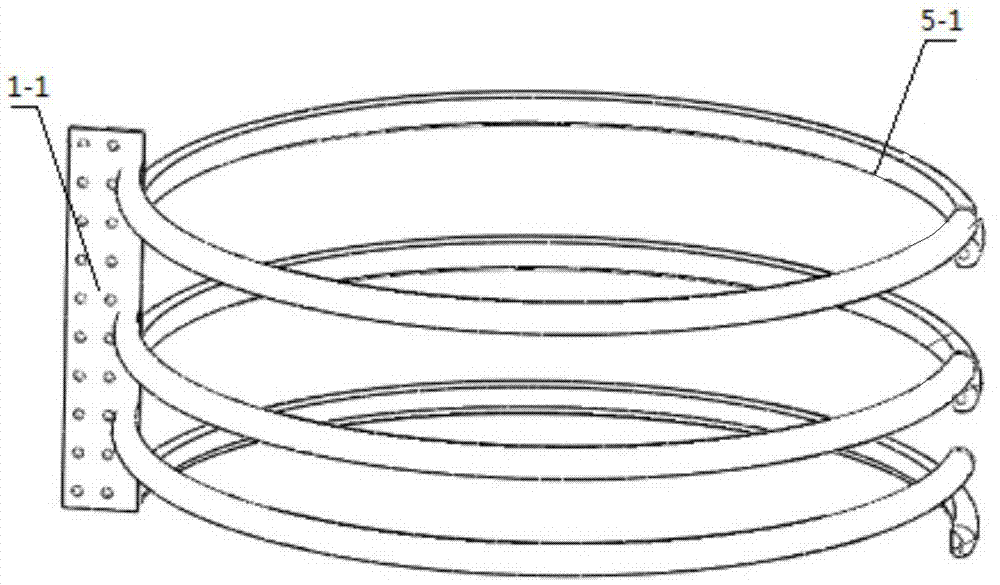

[0047] Such as Figure 6 As shown, an auxiliary cooling device applied to a refrigerator compressor is an auxiliary cooling device for a compressor based on a loop heat pipe 5-2 and cooling fins 1-2, and mainly includes a compressor upper casing 2 and a compressor lower casing 6. Loop heat pipe 5-2, cooling fin 1-2. The upper casing 2 of the compressor is in the shape of a cylindrical cover, and the top end is a small arc surface; the lower casing 6 of the compressor is also in the shape of a cylindrical cover, and the lower end is designed with a base 3, and there are four fixing bolt holes 4 on the base 3; The casing 2 and the lower casing 6 of the compressor are connected to each other to form a closed space, and are assembled into an outer casing of the compressor to protect internal components of the compressor. The loop heat pipe 5-2 is in a spiral shape, one of which surrounds the side of the compressor; the cooling fins 1-2 are embedded in the loop heat pipe 5-2, arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com