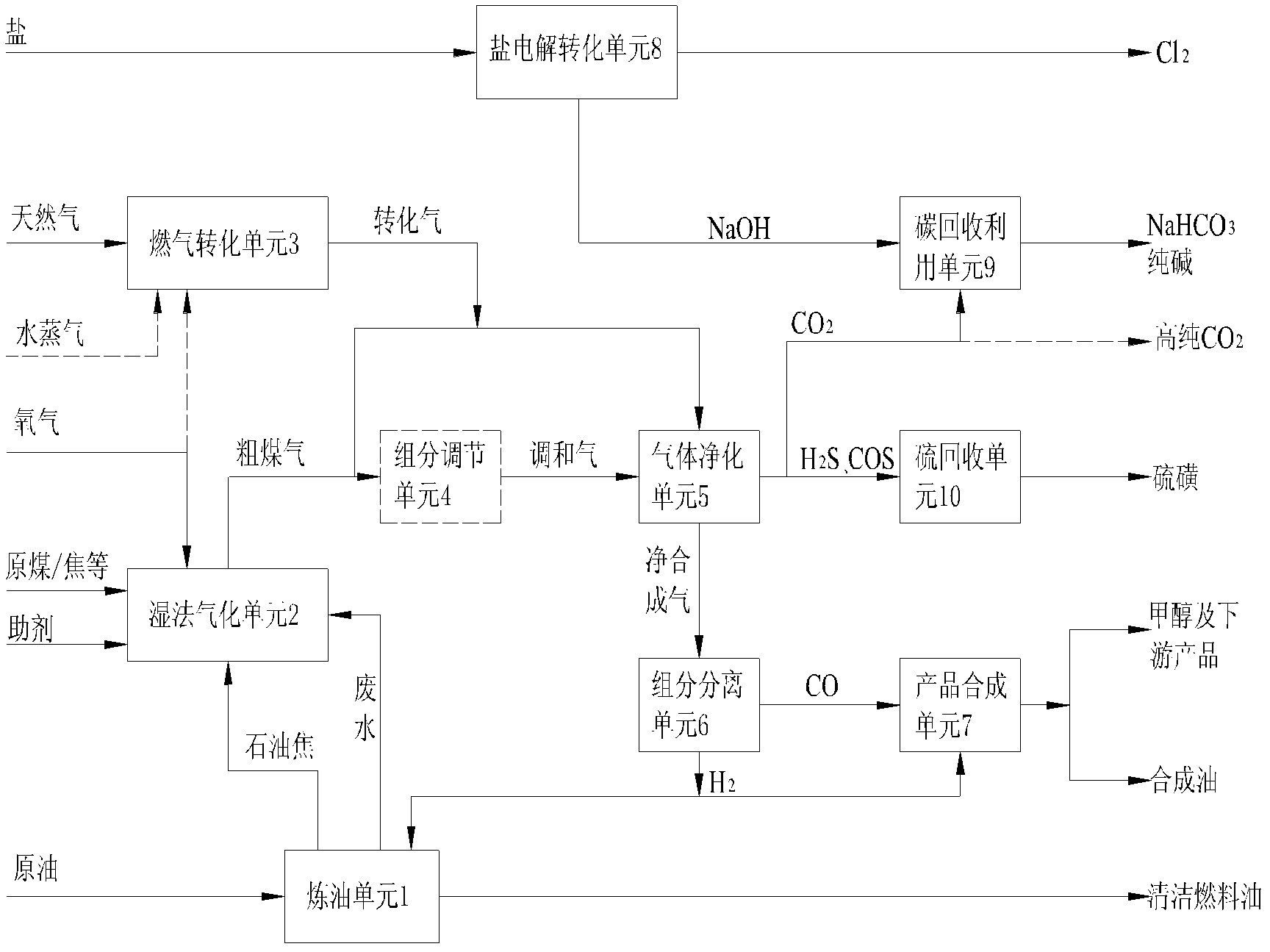

Method for co-producing various chemical products by taking coal, petroleum, natural gas and salt as raw materials

A technology of chemical products and natural gas, which is applied in the field of joint production of various chemical products, and can solve problems such as the lack of better utilization of resources and the waste of natural gas resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

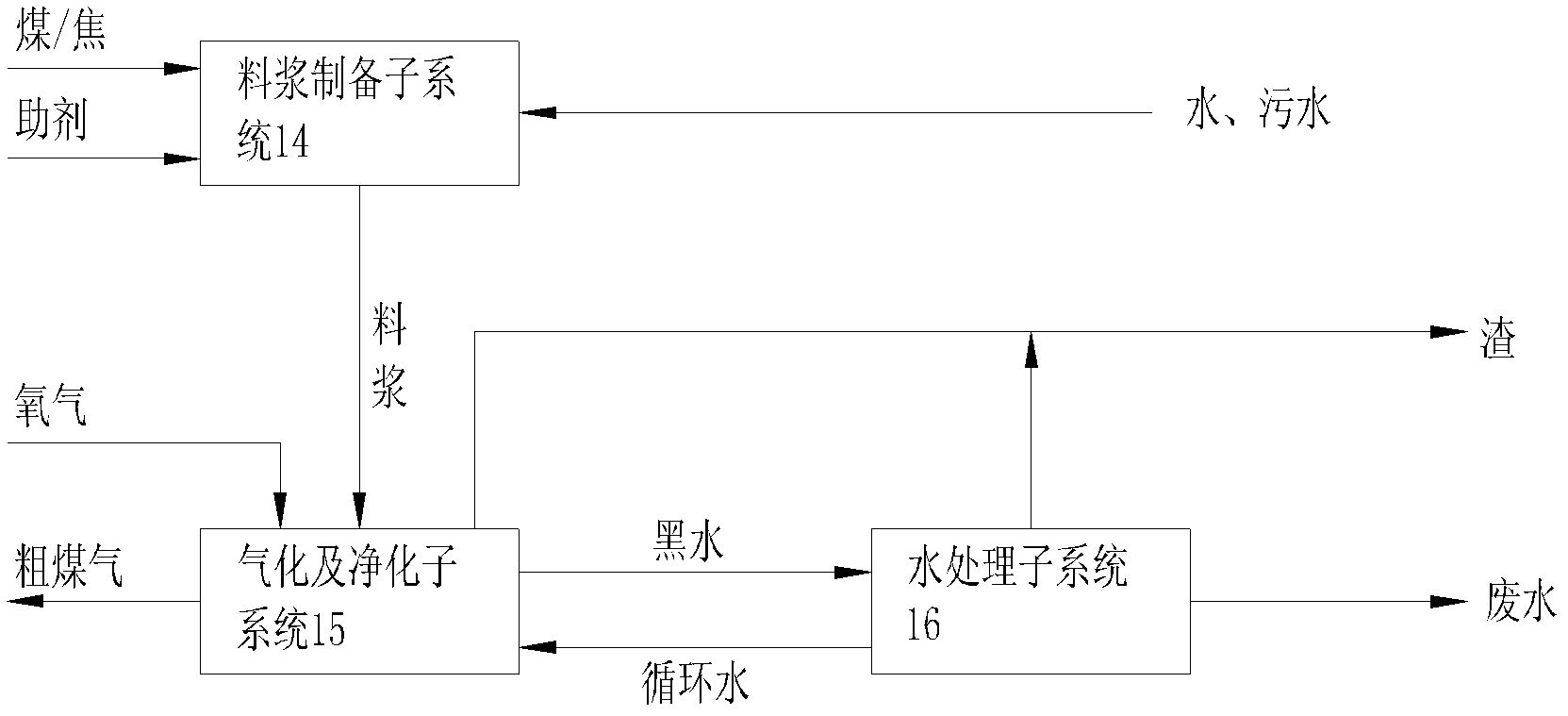

Method used

Image

Examples

Embodiment 1

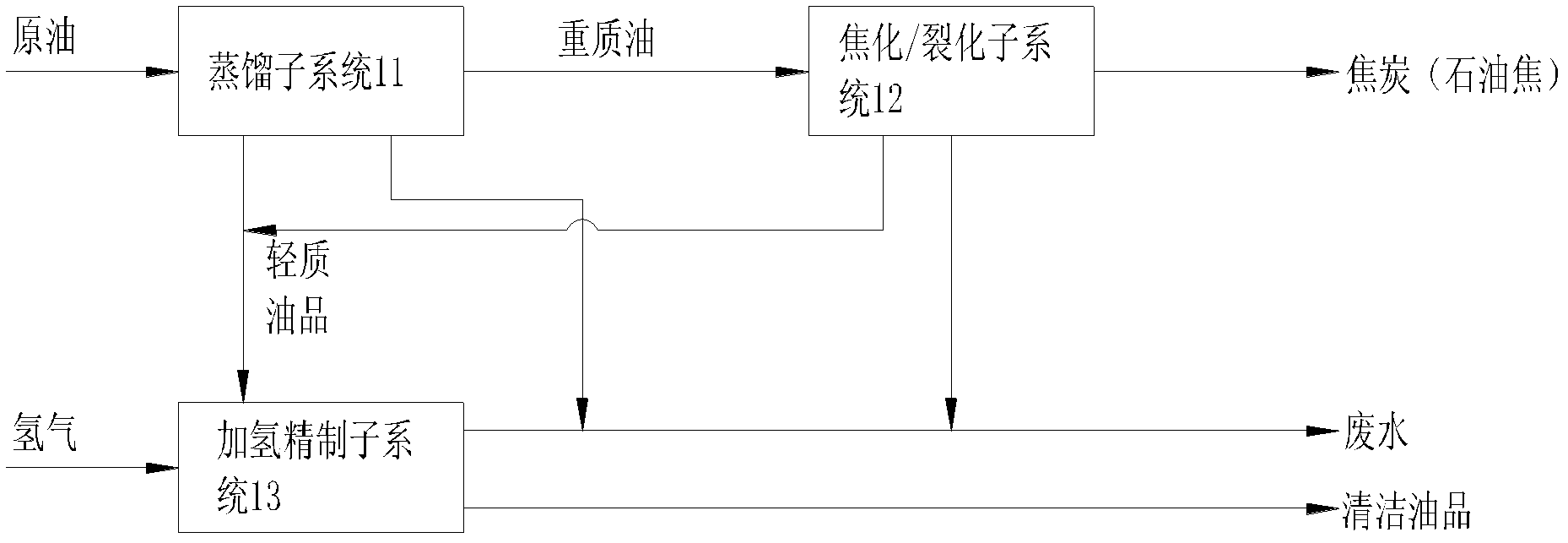

[0082] In a certain year, 1 million tons of oil, 600,000 tons of coal, and 600 million Nm of natural gas (associated gas and coalbed methane) are processed 3 and 2 million tons of salt to clean fuel oil, methanol, Cl 2 , soda ash and sulfur as the main products of the polygeneration system of chemical products is a demonstration device of the present invention, all material flows in this embodiment are measured in hours.

[0083] Petroleum enters the refining unit (1) with a processing capacity of 140t (sulfur content 1.51%, mass percentage), and after being processed by the distillation subsystem, about 43.76t of light oil and 63t of heavy oil are produced, and the heavy oil is coked After further processing by the cracking subsystem (12), 37.8t of petroleum coke (2.31% sulfur content, mass percentage) and about 19.2t of light oil products are produced, and the others are low-molecular organic substances. The fuel oil produced by the distillation subsystem (11) and the cokin...

Embodiment 2

[0098] In a certain year, 2.5 million tons of oil, 700,000 tons of coal, 200,000 tons of low-temperature pyrolysis semi-coke, and 1 billion Nm of natural gas (associated gas and coalbed methane) are processed 3 and 3 million tons of salt to clean fuel oil, synthetic oil, Cl 2 , soda ash, sulfur, high-purity CO 2 A polygeneration system for chemical products as the main product is an exemplary plant of the present invention.

[0099] The process is the same as the above-mentioned embodiment 1, except that the product synthesis unit (7) is a Fischer-Tropsch synthetic oil process to produce synthetic fuel oil. In addition, this system process will also extract part of the CO produced by the process. 2 Gas, exported as product. For convenience of description, this embodiment only lists process raw material consumption / product output and emission reduction effects.

[0100] Table 4 Main raw material consumption and product output of the system

[0101]

[0102] Table 5 List ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com