Two-stage mass-flow oblique flow compressor with stage intercooling

A diagonal flow compressor and interstage cooling technology, applied in the field of compressors, can solve the problems of poor performance of the first stage compressor and difficulty in adapting to the needs of extra-large flow air separation units, so as to improve the anti-distortion ability and widen the working condition range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only for explaining the present invention, and are not intended to limit the present invention.

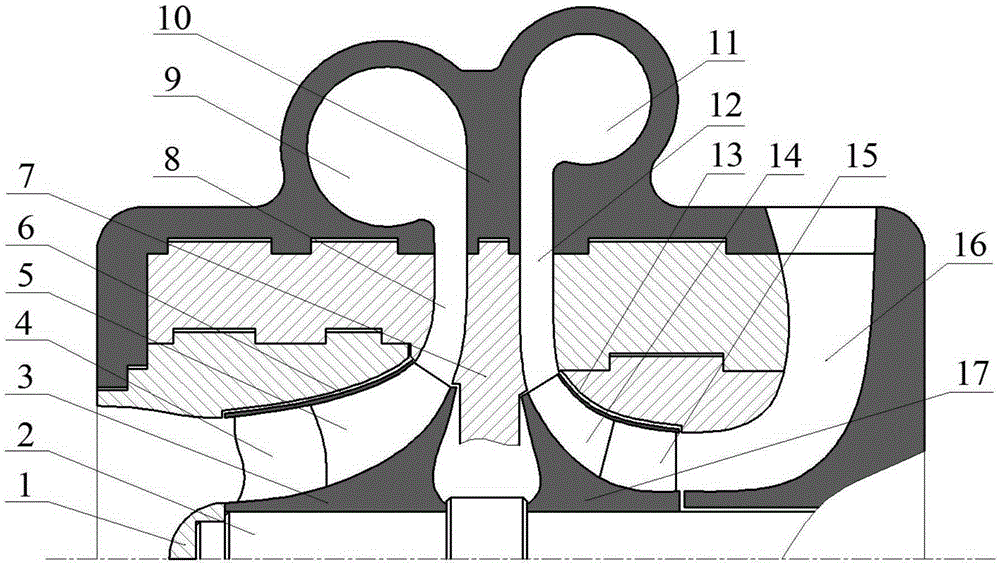

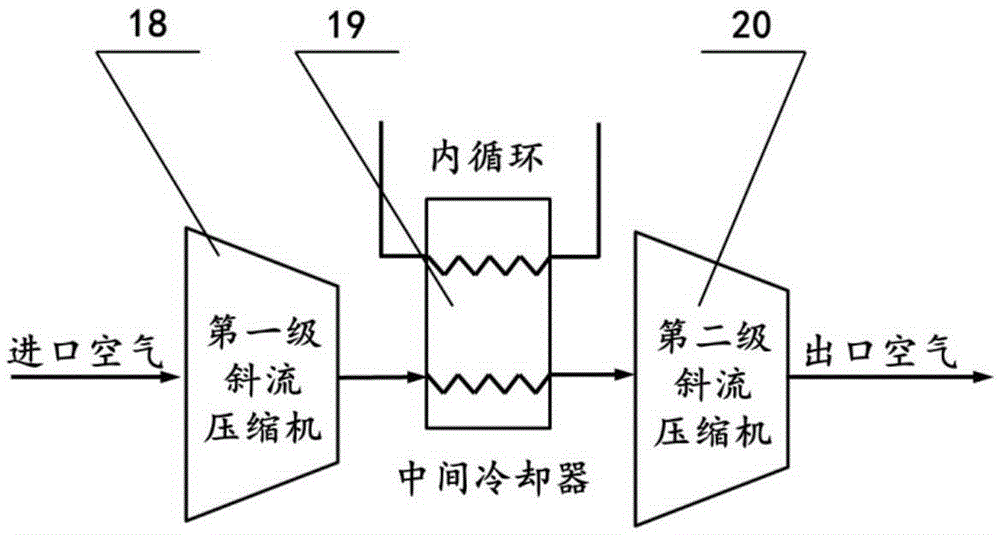

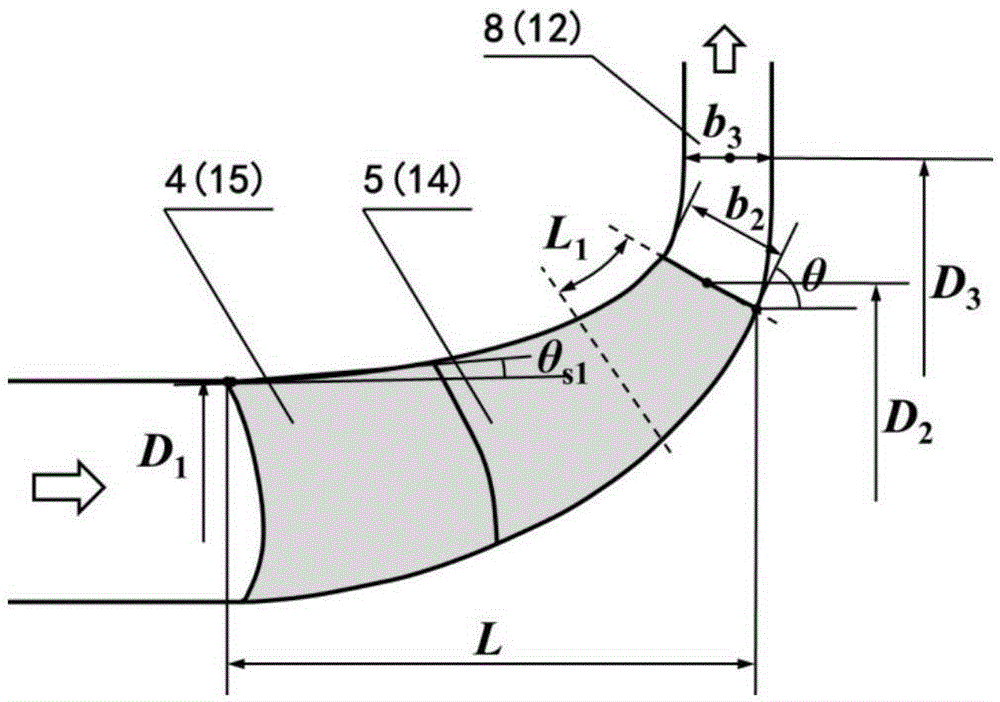

[0052] see Figure 1~4 , the present invention is a two-stage large-flow mixed-flow compressor with interstage cooling, including a first-stage mixed-flow compressor 18 and a second-stage mixed-flow compressor 20 . The first stage oblique flow compressor 18 consists of the first stage oblique flow impeller (including the first oblique flow impeller disk 3, the first oblique flow impeller main blade 4, the first oblique flow impeller splitter blade 5 and the first The oblique flow impeller cover 6), the first stage oblique flow vaneless diffuser 8, the first stage volute 9; the second oblique flow compressor 20 is composed of the second oblique flow impeller (including the second oblique flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com