Patents

Literature

37results about "Oxygen compounds by oxo-reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimerized alcohol compositions and biodegradible surfactants made therefrom having cold water detergency

InactiveUS6222077B1Good cold water detergencyOrganic detergent compounding agentsOther chemical processesDouble bondCarboxylic acid

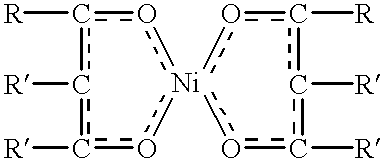

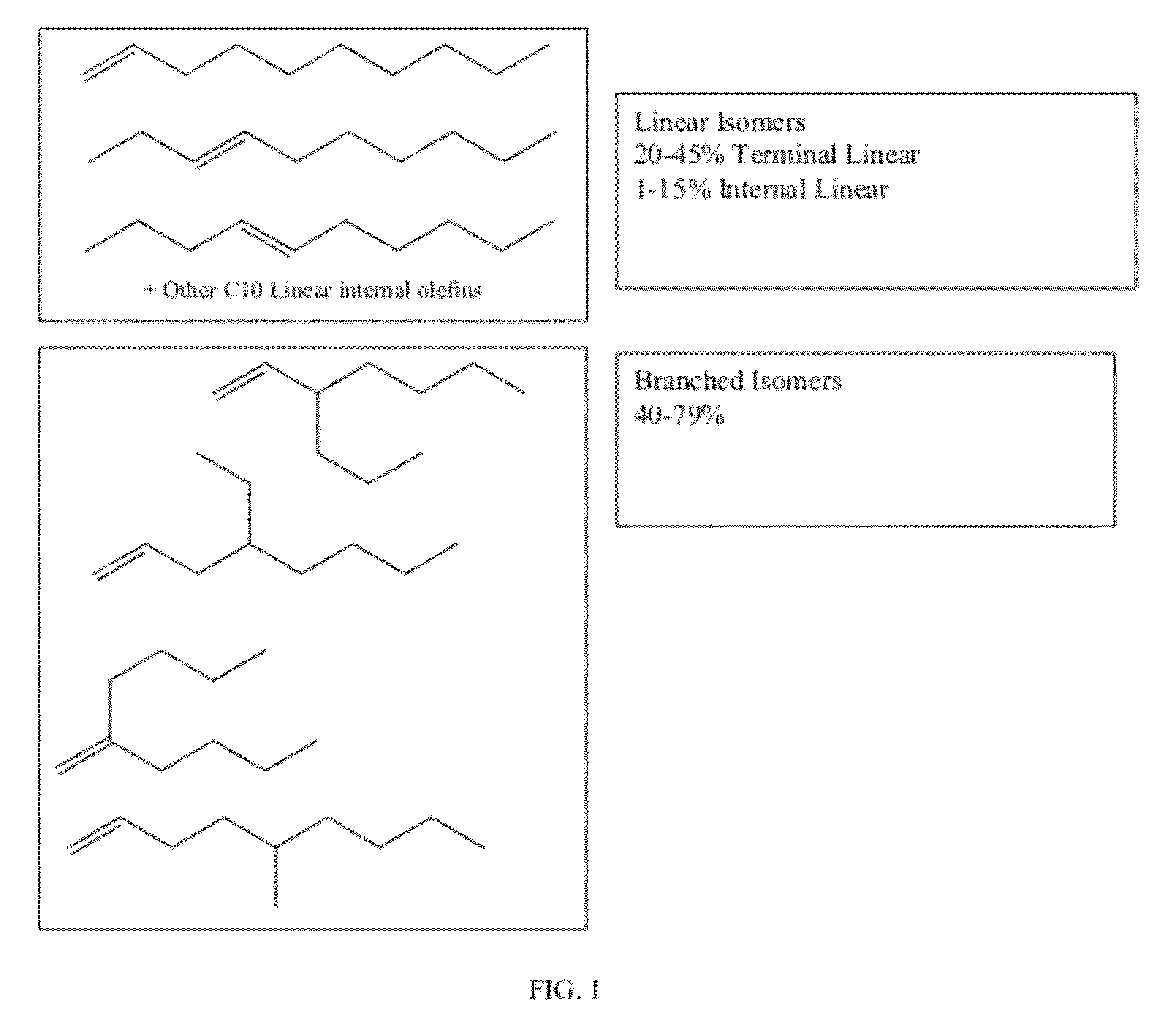

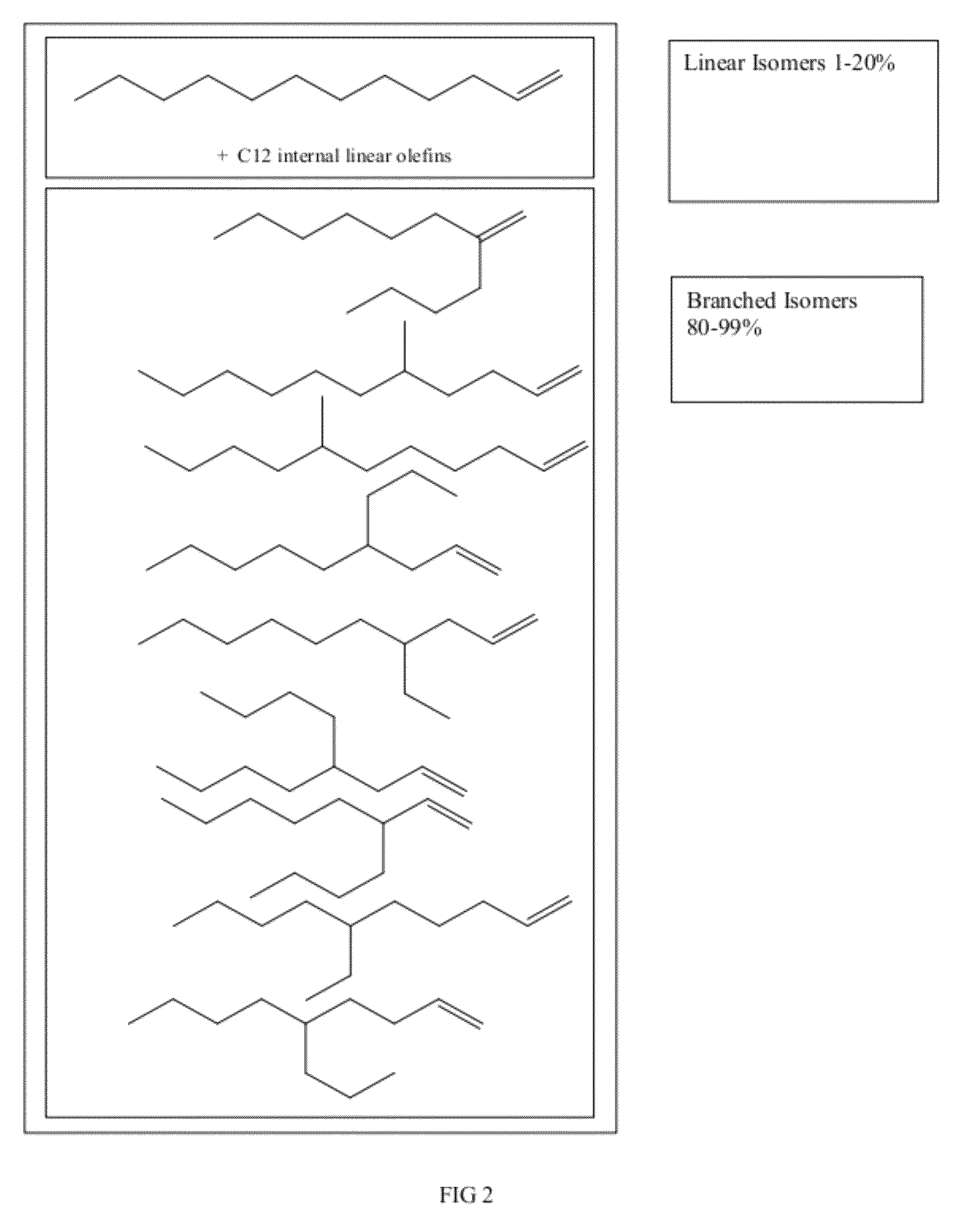

There is provided an alcohol composition obtained by dimerizing an olefin feed comprising C6-C10 linear olefins to obtain C12-C20 olefins, followed by conversion to alcohols, such as by hydroformylation. The composition has an average number of branches ranging from 0.9 to 2.0 per molecule. The linear olefin feed preferably comprises at least 85% of C6-C8-olefins. The primary alcohol compositions are then converted to anionic or nonionic surfactants, preferably sulfated or oxyalkylated or both. The sulfated compositions are biodegradable and possess good cold water detergency. The process for making the dimerized primary alcohol comprises dimerizing, in the presence of a homogeneous dimerization catalyst under dimerization conditions, an olefin feed comprising C6-C10 olefins and preferably at least 85 weight % of linear olefins based on the weight of the olefin feed, to obtain a C12-C20; optionally double bond isomerizing said C12-C20 olefins; and converting the C12-C20 olefins to alcohols, preferably through hydroformylation. The process is preferably a one-step dimerization. The homogenous catalyst comprises a mixture of a nickel carboxylate or a nickel chelate, with an alkyl aluminum halide or an alkyl aluminum alkoxide.

Owner:SHELL OIL CO

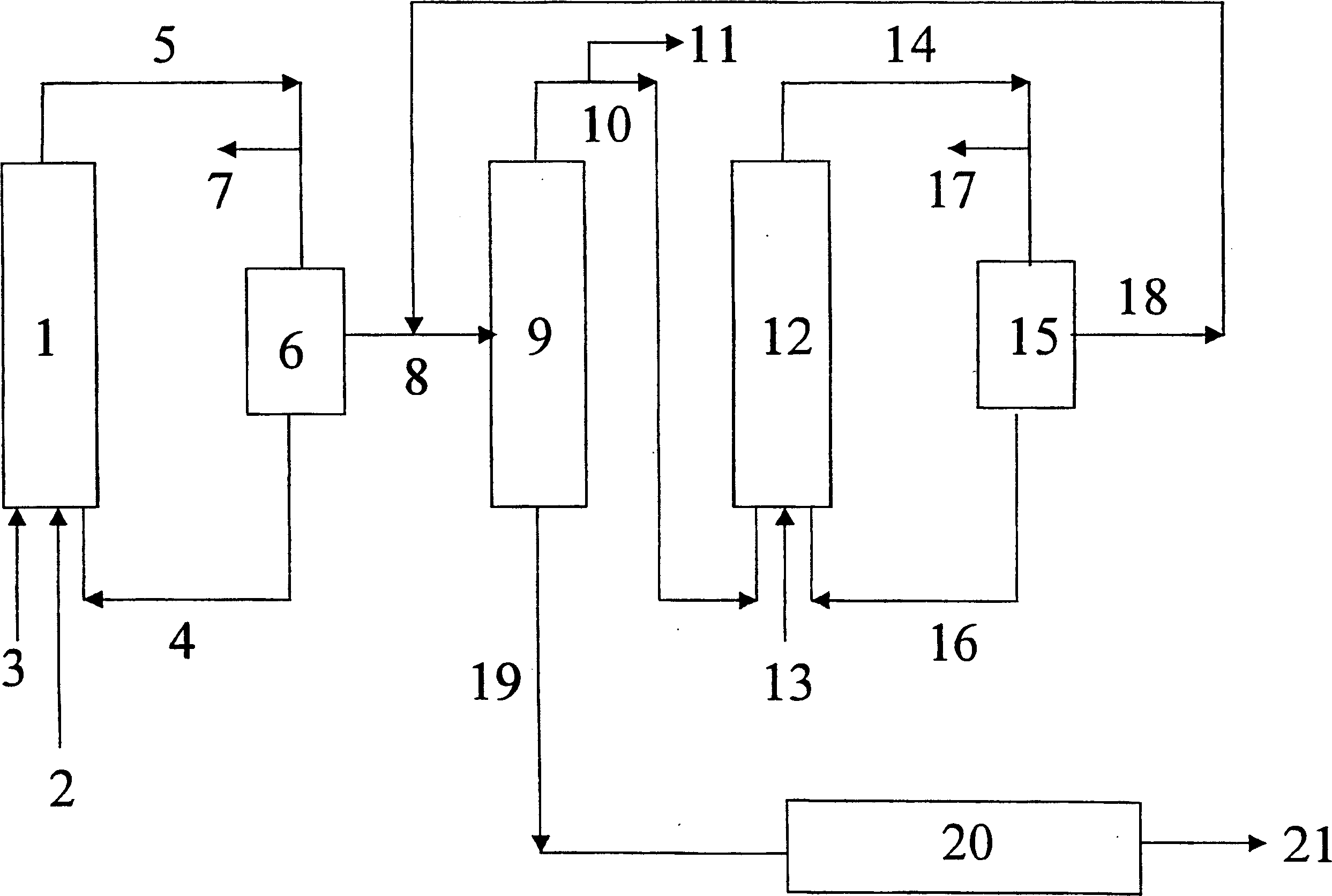

Process for the conversion of hydrocarbons into ethanol

ActiveUS7947746B2Increased formationIncreased purge stepOrganic compound preparationOxygen compounds preparation by reductionAcetic acidAlcohol

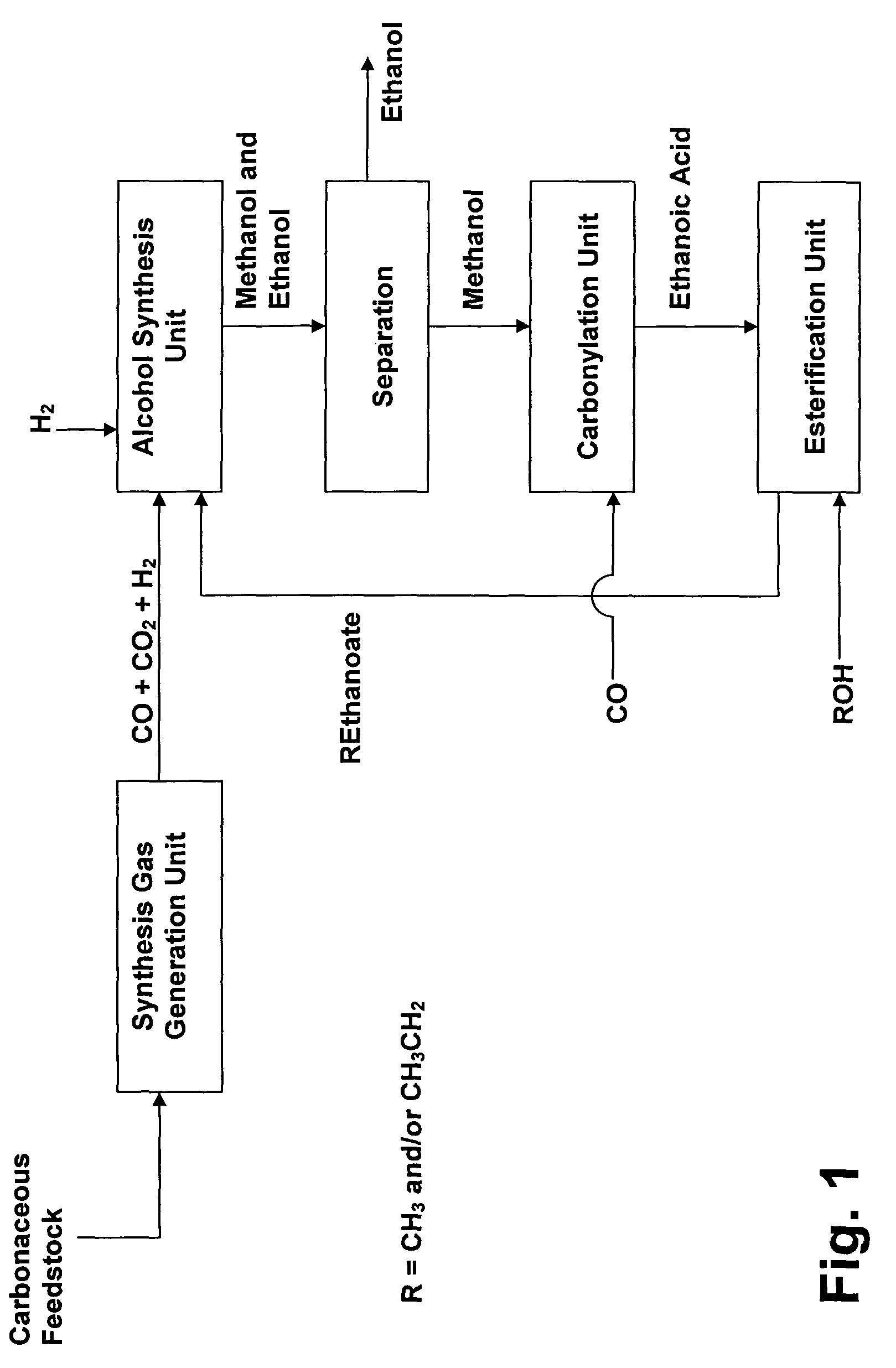

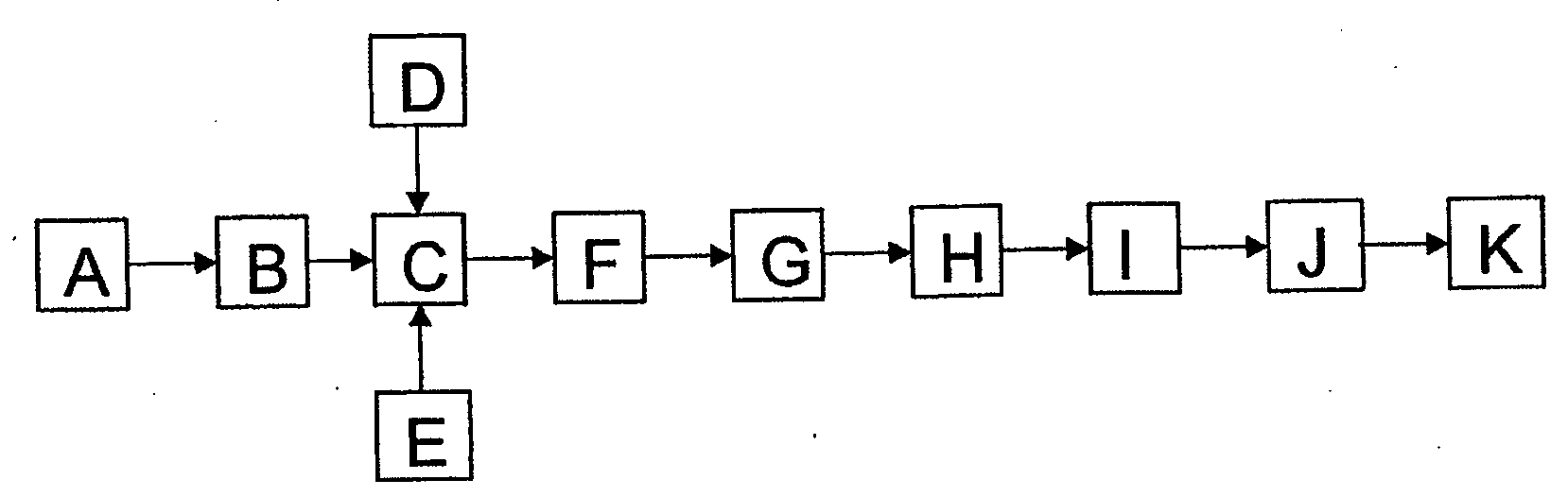

Process for converting synthesis gas to ethanol, including the steps of 1) introducing synthesis gas, together with methyl ethanoate and / or ethyl ethanoate, into an alcohol synthesis unit to produce methanol and ethanol, 2) separating the methanol from the ethanol of step 1, 3) introducing methanol, from step 2, together with CO, into a carbonylation unit in the presence of a methanol carbonylation catalyst, to produce ethanoic acid, and 4) introducing ethanoic acid, from step 3, together with methanol and / or ethanol, into an esterification unit to produce methyl ethanoate and / or ethyl ethanoate. In step 5), methyl ethanoate and / or ethyl ethanoate, produced in step 4, are fed into the alcohol synthesis unit of step 1, and in step 6) ethanol from step 2 is recovered.

Owner:INEOS ACETYLS UK LTD

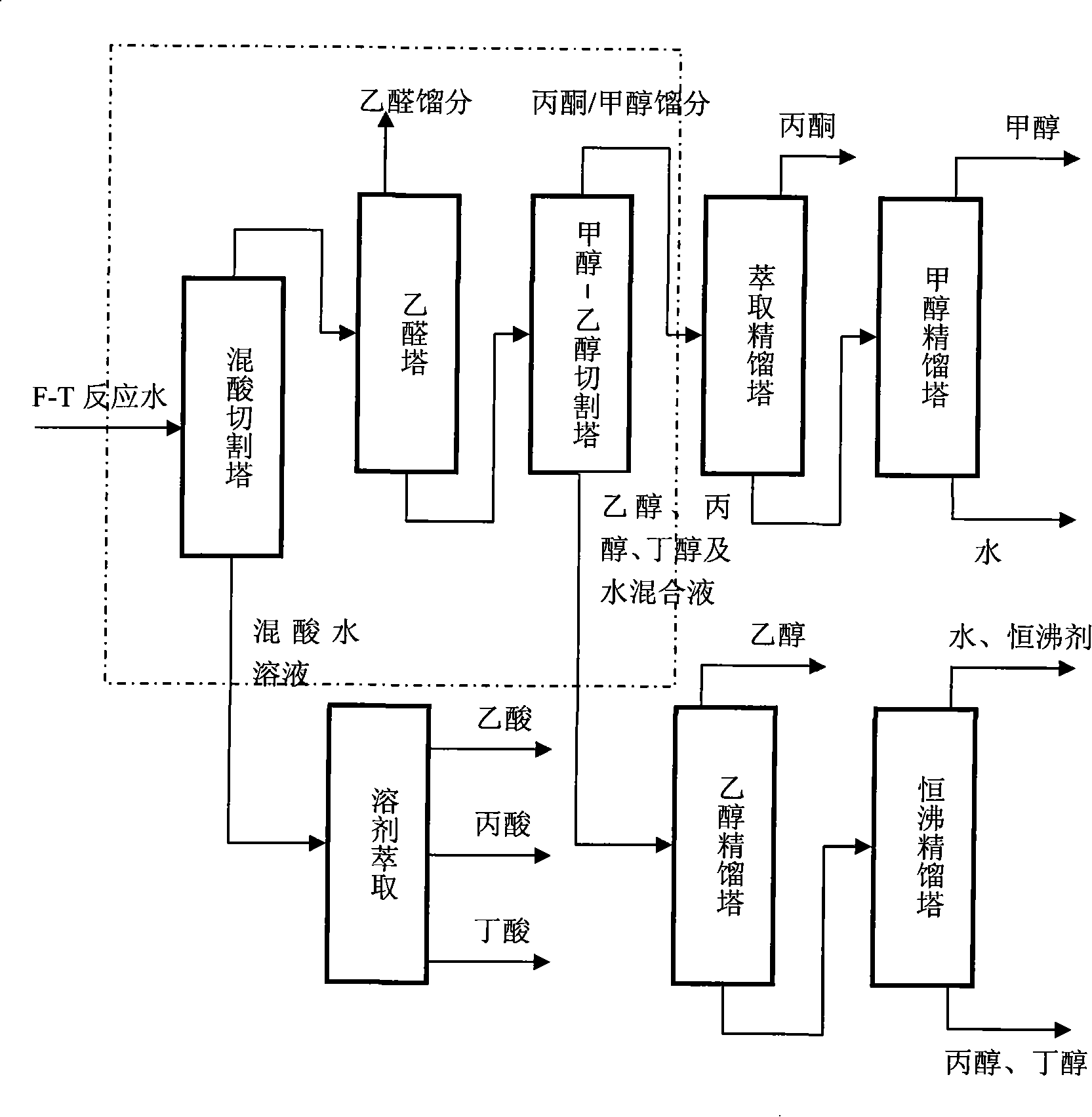

Method for separating and reclaiming organic matter from high-temperature Fischer-Tropsch synthesis reaction water

ActiveCN101239886AEffective and orderly separation and recoveryOrderly separation and recoveryOrganic compound preparationHydroxy compound preparationRecovery methodKetone

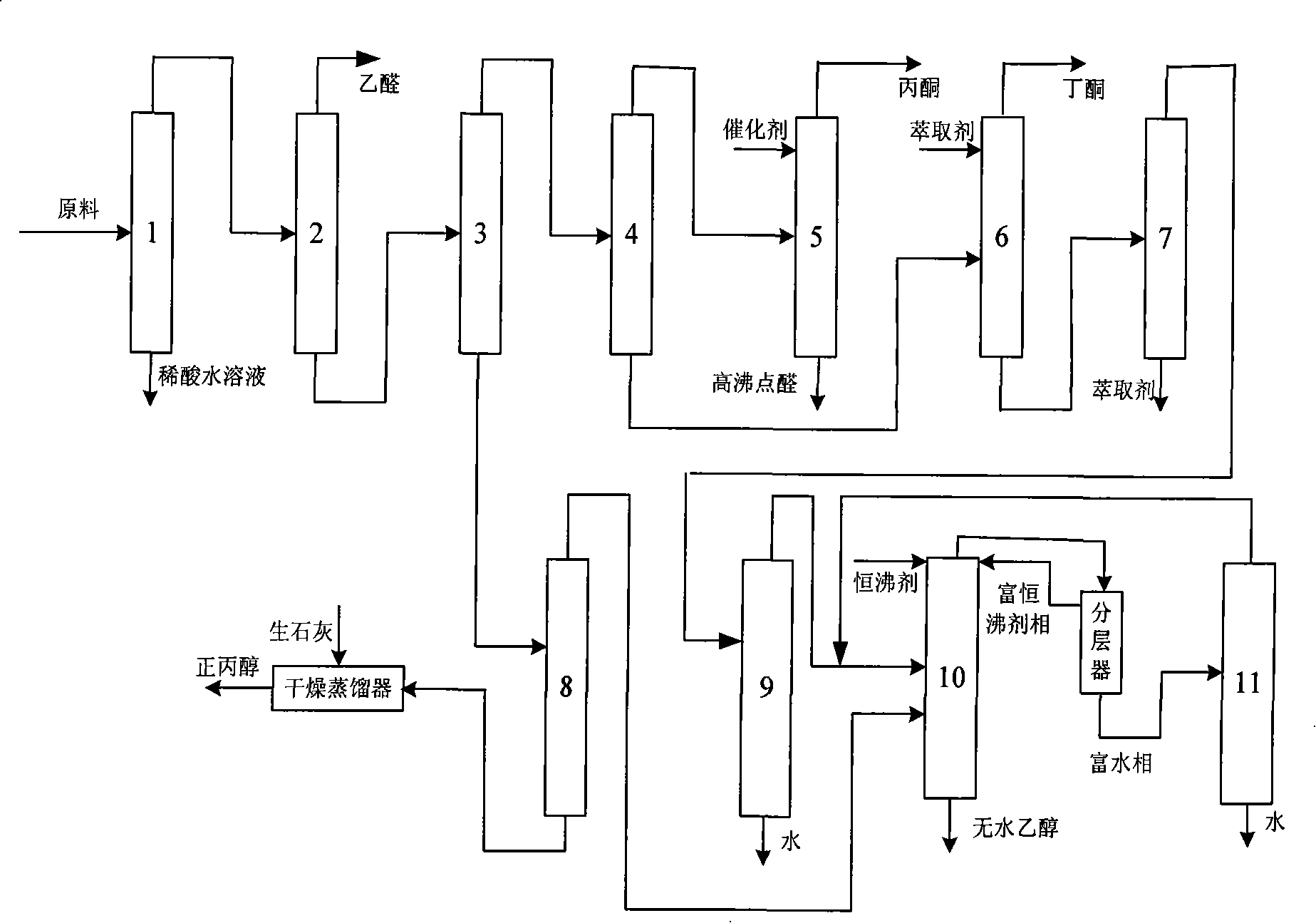

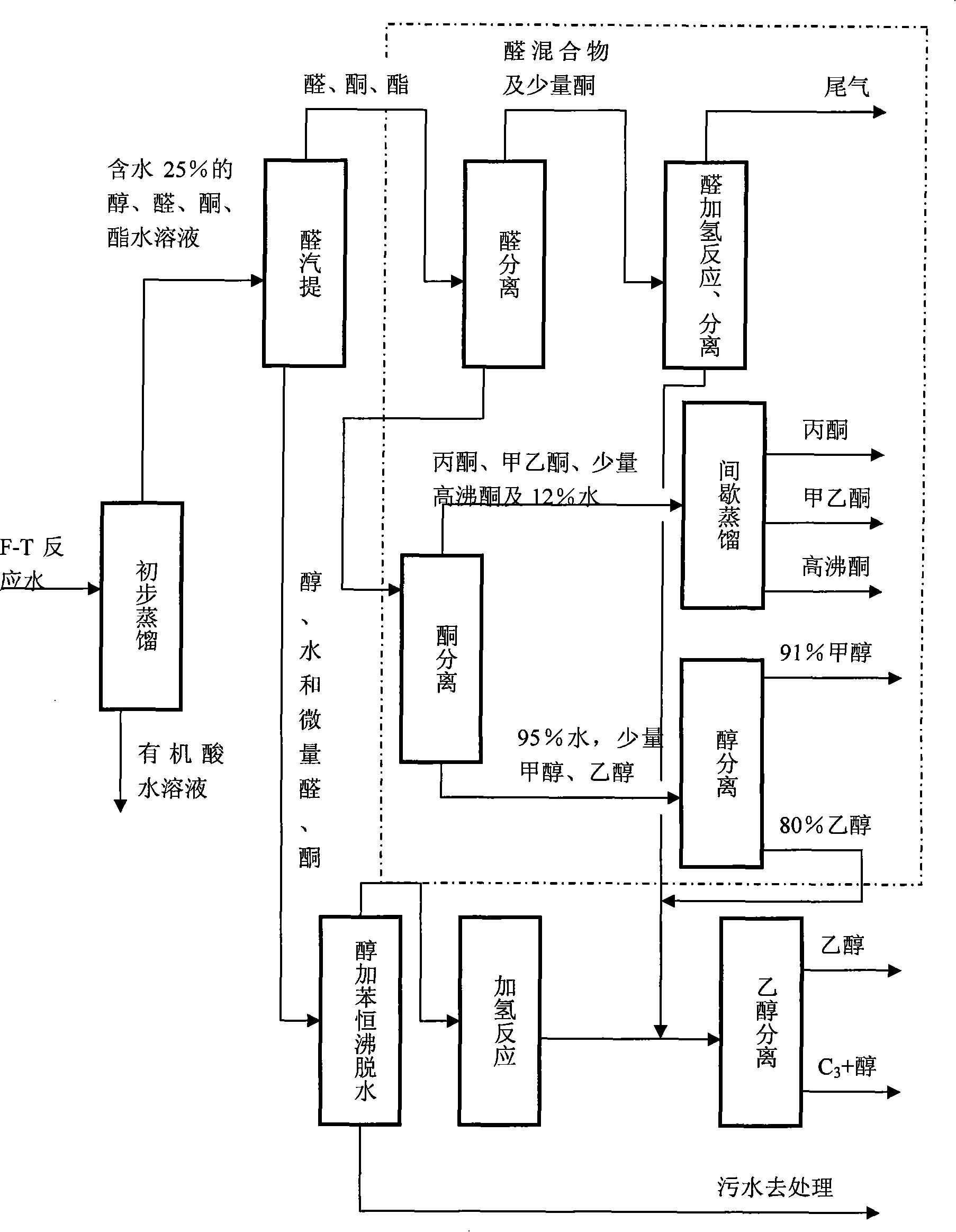

The invention relates to a separation and recovery method of organic matters in high-temperature Fischer-Tropsch synthesis reaction water. The method comprises steps of: (1) separating and recoverying aldehyde after rectifying and removing organic acid; (2) rectifying and separating ketone / n-propanol; (3) rectifying and separating acetone / butanone; (4) refining acetone; (5) extracting and separating butanone / ethanol; (6) rectifying and separating ethanol / n-propanol; further rectifying alcohol-containing aqueous sollution obatained from the bottom of a column for rectifying and separating ketone / n-propanol, ethanol containing little water and obtained from the top of the column, and n-propanol alcohol-containing aqueous sollution obatained from the bottom of the column; (7) azeotropic rectifying ethanol sollution obtained by exaction and separation, and ethanol sollution with n-propanol separated to prepare anhydrous ethanol; (8) adding calces in n-propanol aqueous sollution, distilling to obtain n-propanol products; the invention effectively and orderly separates and recoveries aldehyde, acetone, butanone, ethanol and n-propanol, the purity of each product is above 95% and the yield is above 90%.

Owner:YANKUANG ENERGY R&D CO LTD

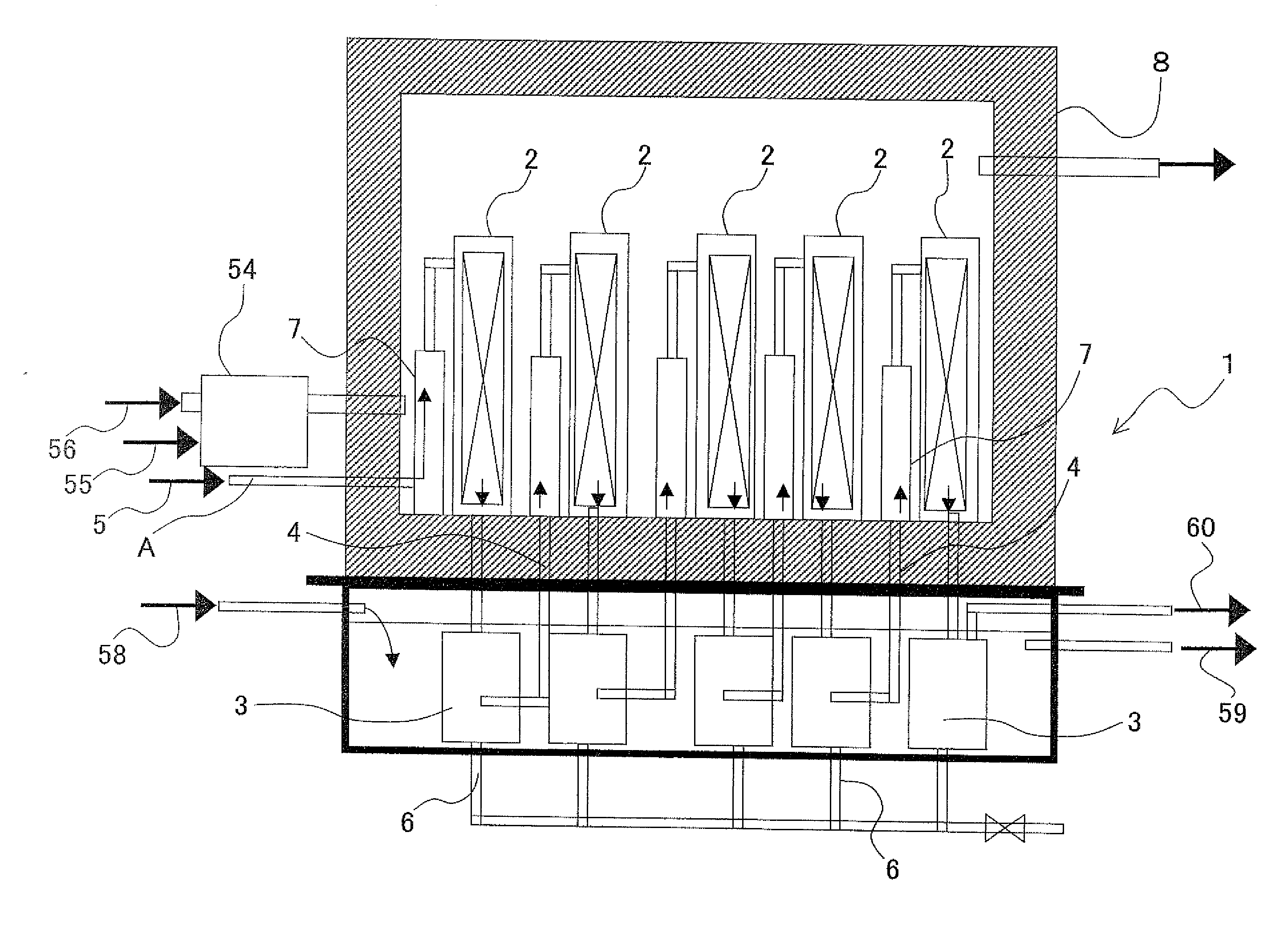

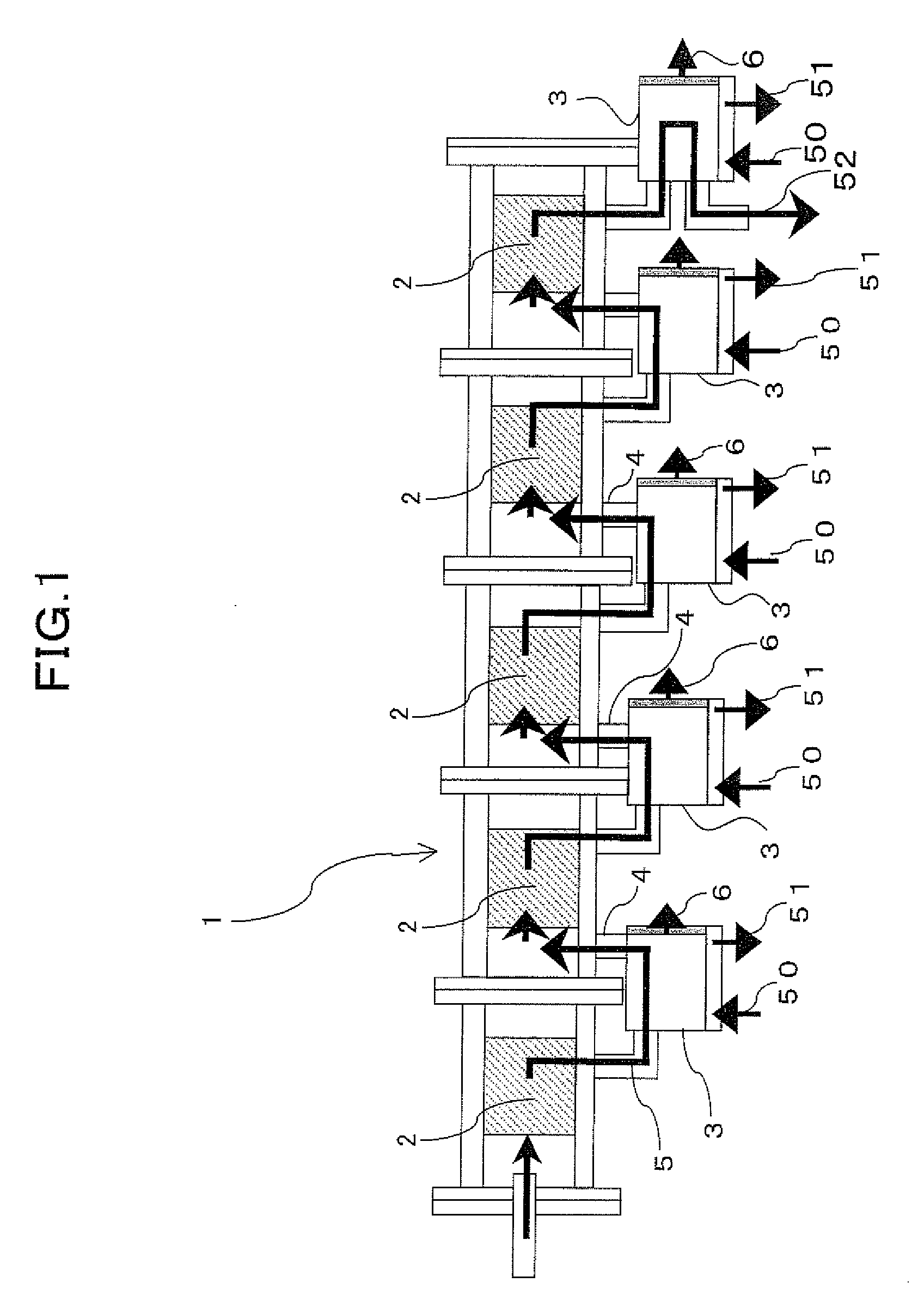

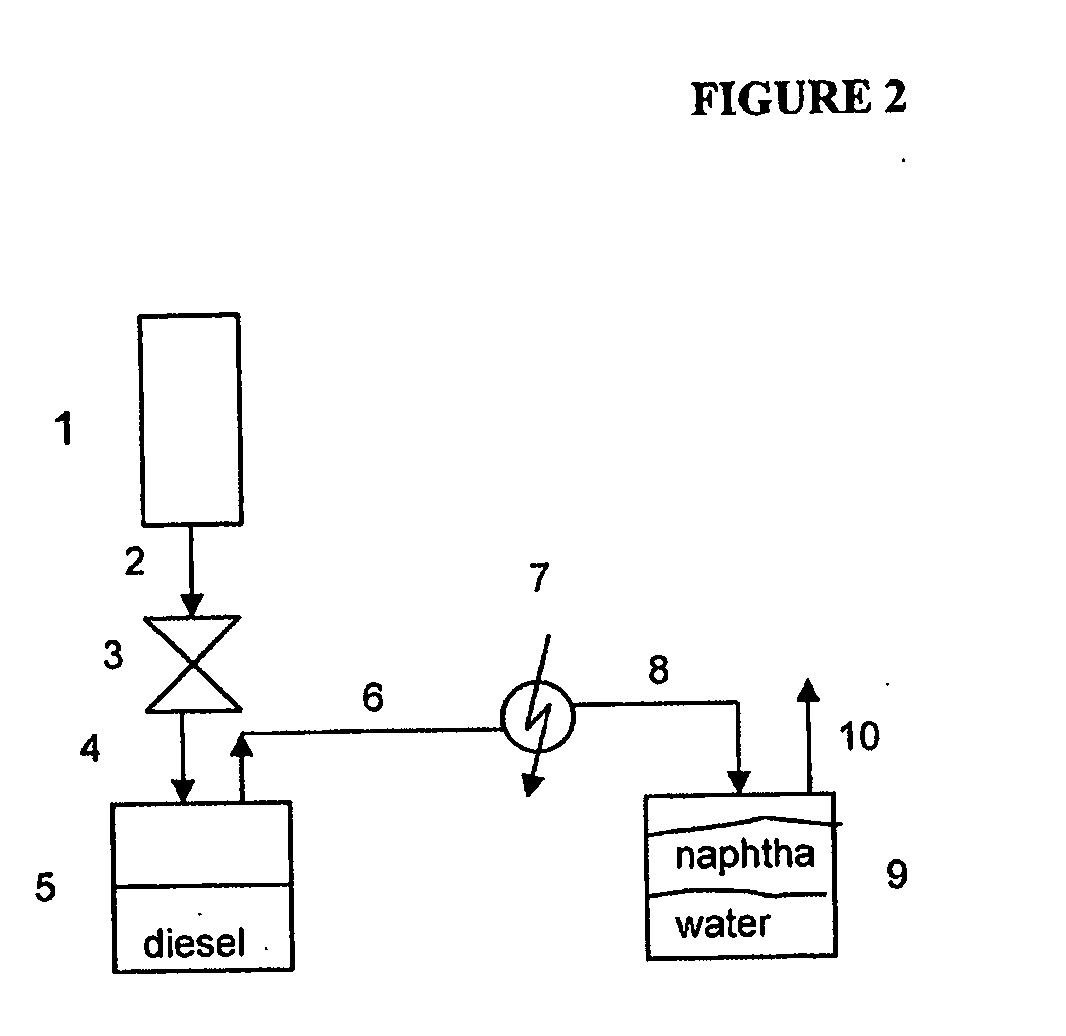

Apparatus and process for production of liquid fuel from biomass

InactiveUS20090318572A1High yieldCooling system is simplifiedOrganic compound preparationOxygen compounds preparation by reductionReaction temperatureProduct gas

The liquid fuel synthesizing apparatus (1) for efficient synthesis of liquid fuel from biomass, such as plant for a raw material, comprised of reactors (2) with a catalyst incorporated therein, coolers (3) for cooling of synthesized gaseous matter and extracting of liquid fuel, and temperature adjustment means (7) for regulating by heat exchange any unreacted gas after recovery of liquid fuel to reaction temperature suitable for liquid fuel gas synthesis, wherein the reactors, the coolers and the temperature adjustment means are arranged multistage inline-straightly along gas flow. The temperature adjustment means (7) and the reactors (2) are disposed in the constant temperature room (8) in parallel. The coolers (3) are disposed apart from the constant temperature rooms (8).

Owner:NAGASAKI INSTITUTE OF APPLIED SCIENCE

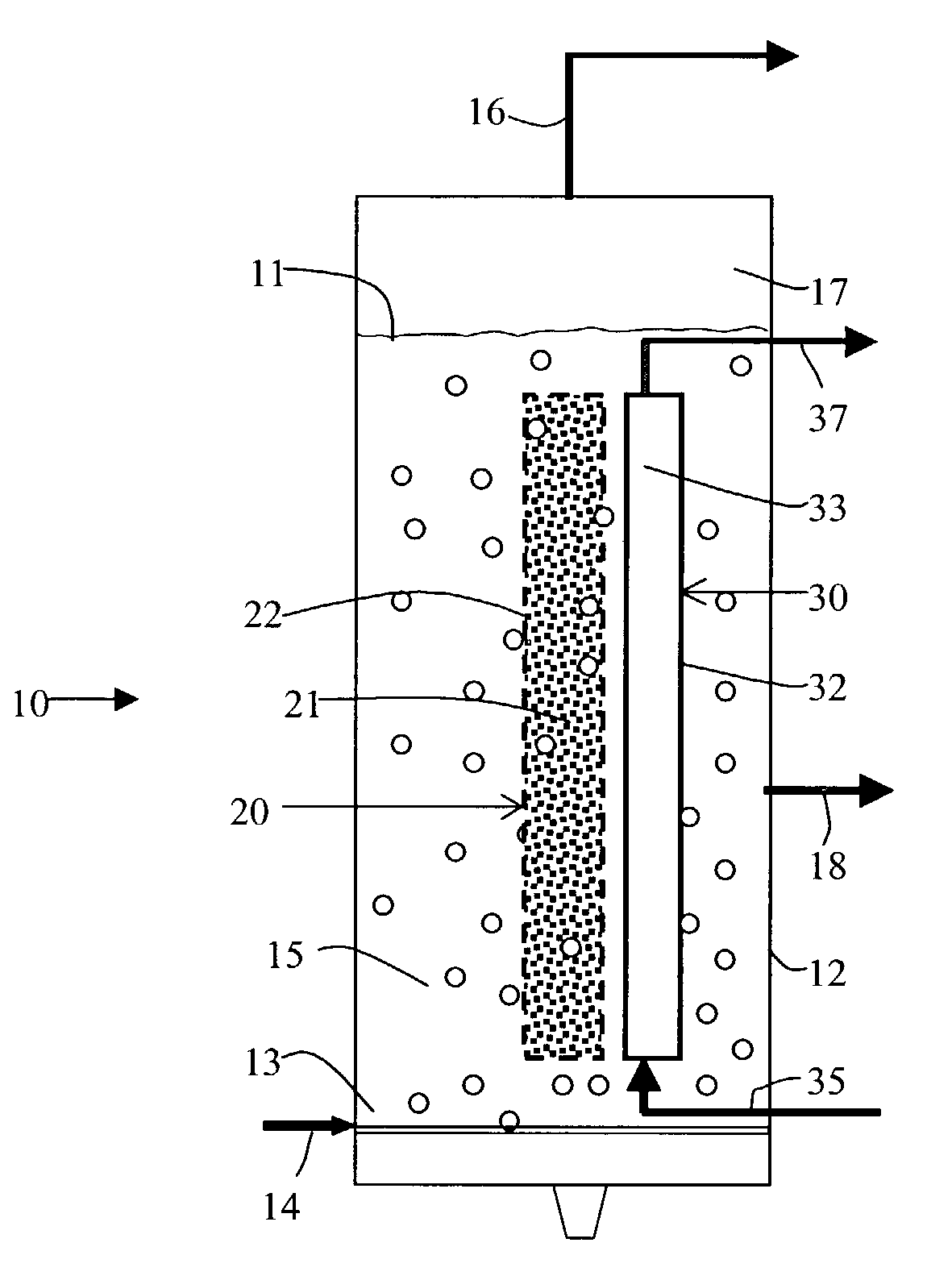

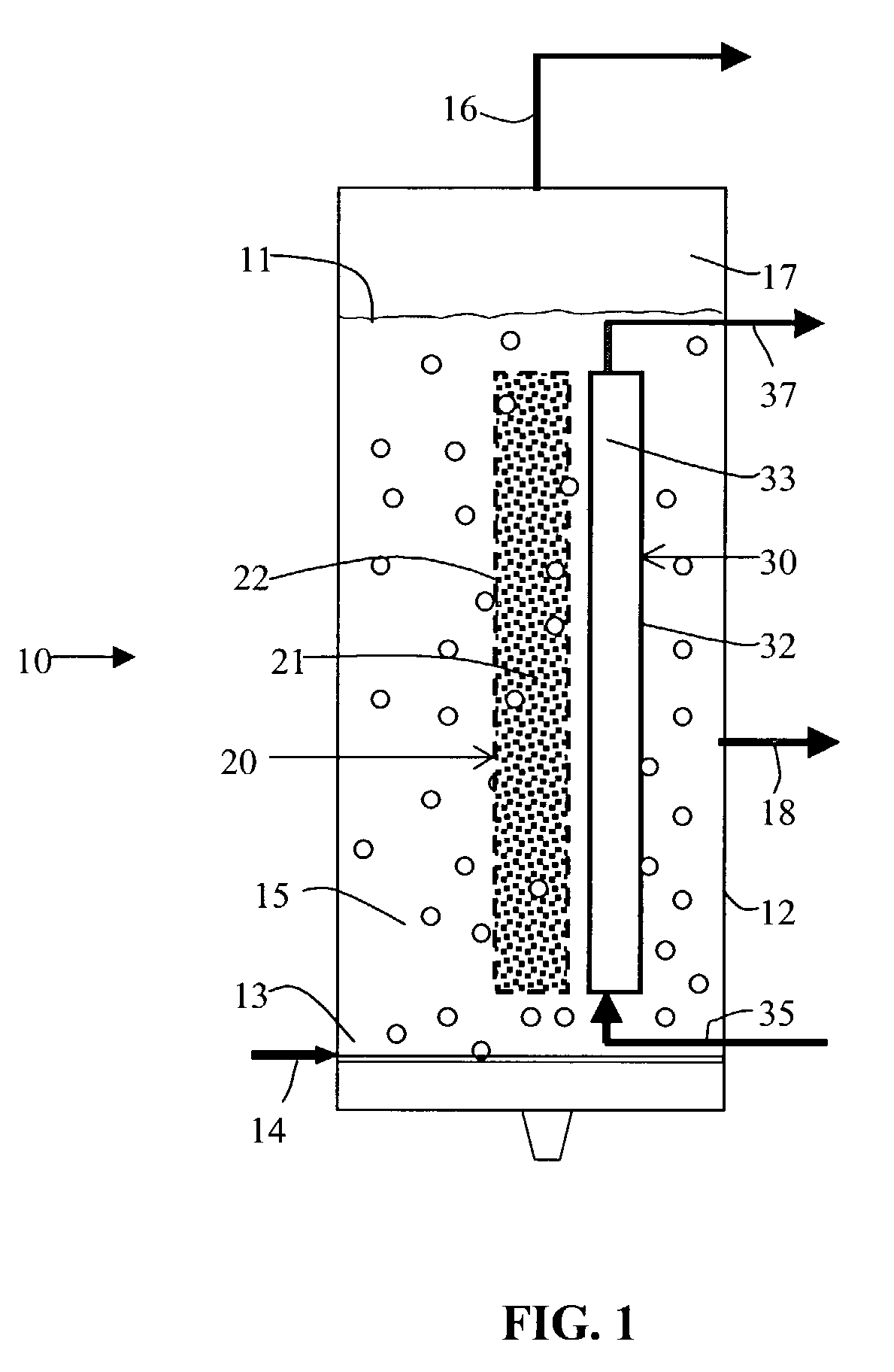

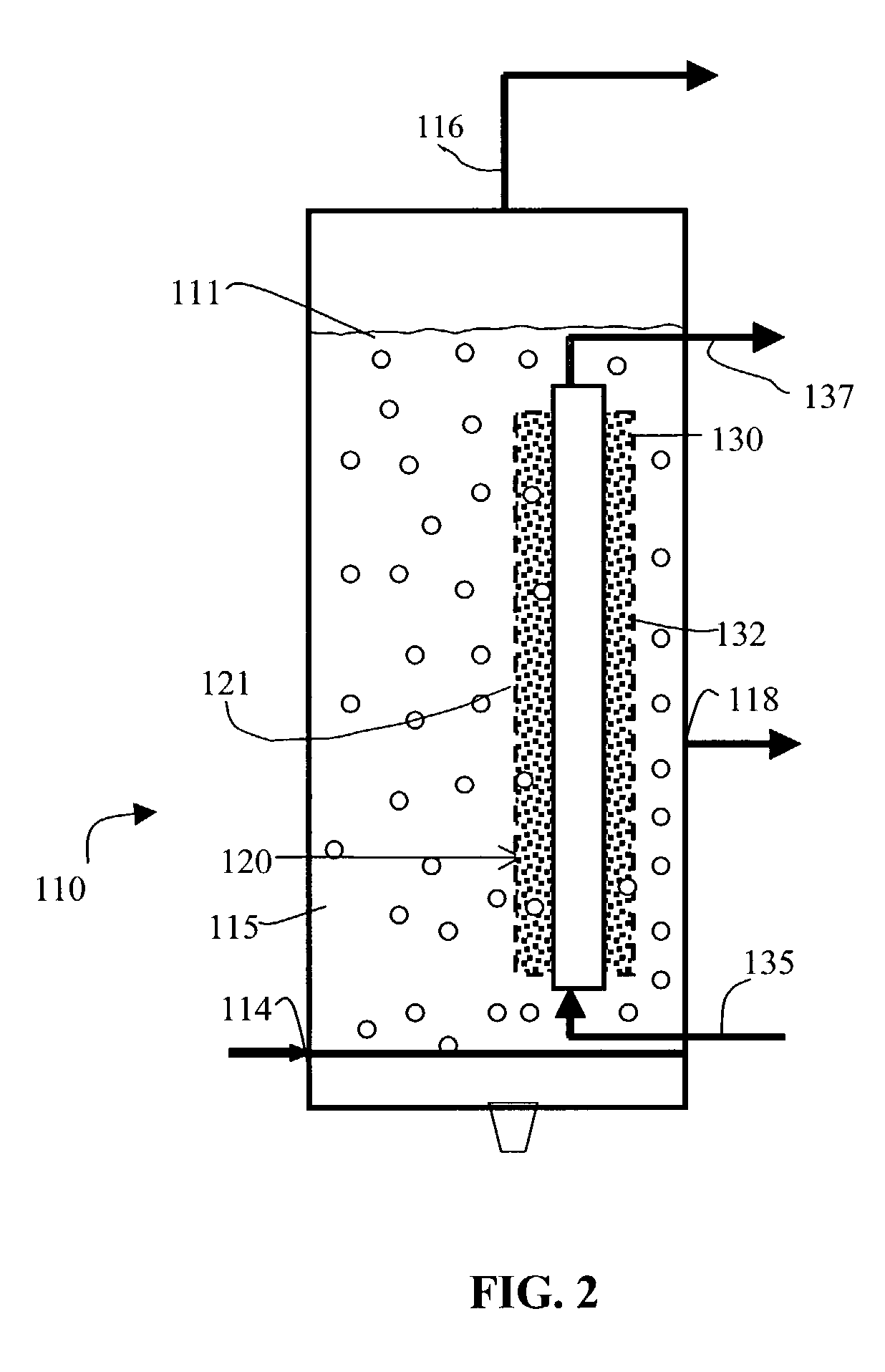

Gas agitated multiphase reactor with stationary catalyst solid phase

ActiveUS7232848B2Improve heat transfer performanceMinimizing catalyst attritionCombination devicesExhaust apparatusLiquid productThermal contact

An apparatus for converting a gaseous and / or liquid feed fluid to gaseous and / or liquid products using a solid catalyst comprises a reactor, a liquid phase disposed within the reactor volume, a fixed catalyst at least partially disposed in the liquid phase, a cooling system having a cooling element in thermal contact with the liquid phase, a feed inlet positioned to feed the feed fluid into the reactor volume, and a fluid outlet in fluid communication with the liquid phase. The catalyst is contained in a catalyst container and the container may be adjacent to said cooling element, extend through said cooling element, or may surround the catalyst container. The catalyst may be a Fischer-Tropsch catalyst.

Owner:PHILLIPS 66 CO

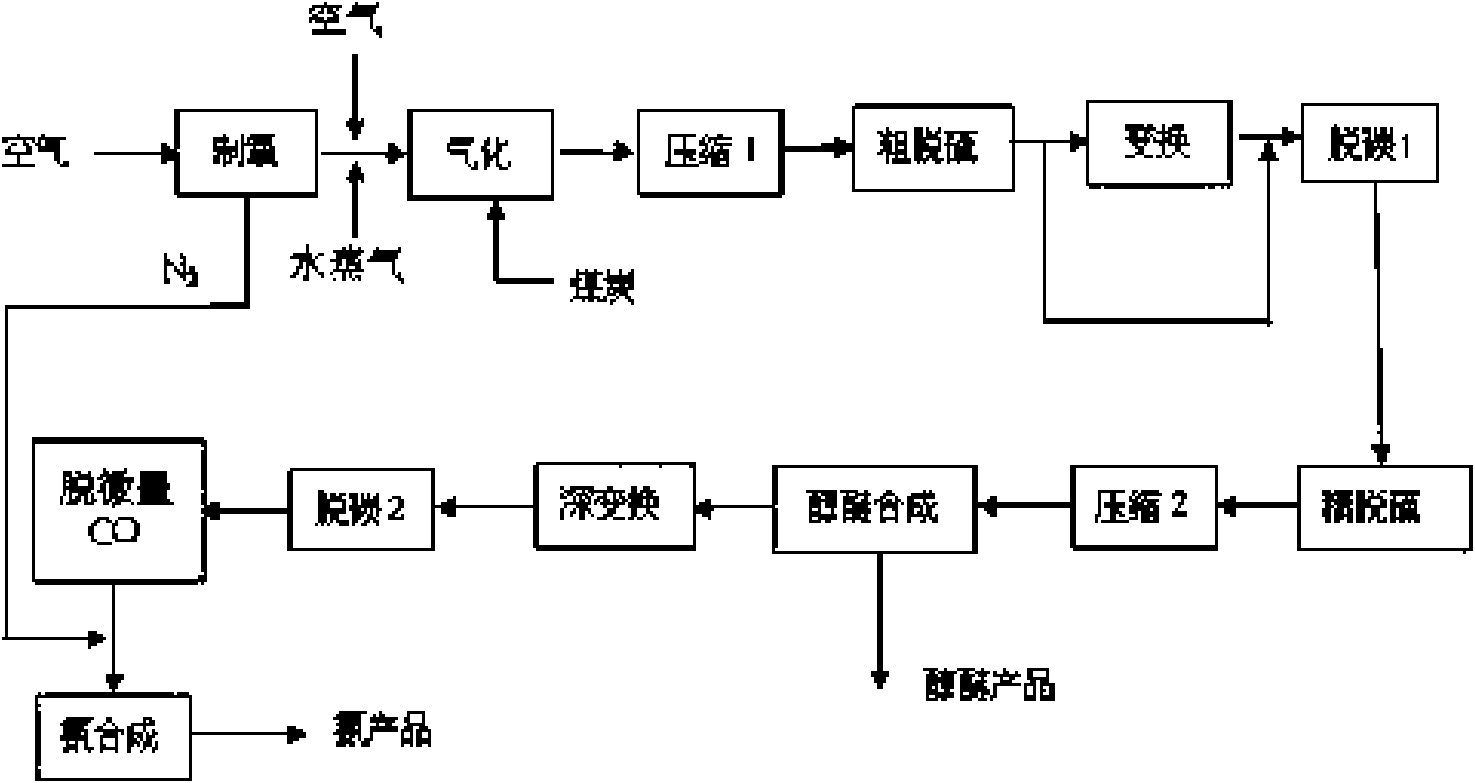

Process for producing alcohol-ether hydrazine under medium/low-pressure

InactiveCN101602649AAvoid disadvantages such as increased energy consumptionReduced Compression Power ConsumptionPreparation by oxo-reaction and reductionOxygen compounds by oxo-reactionProduction lineState of art

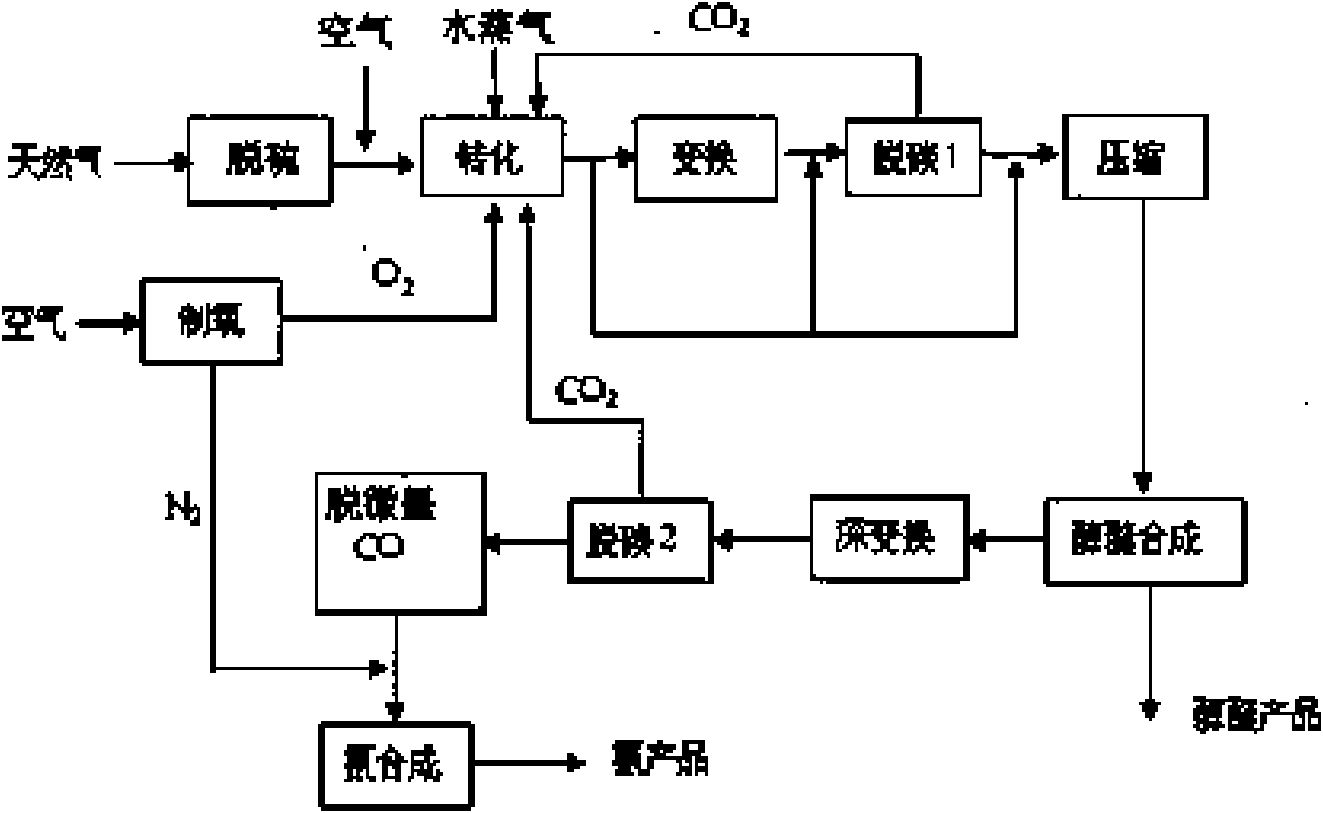

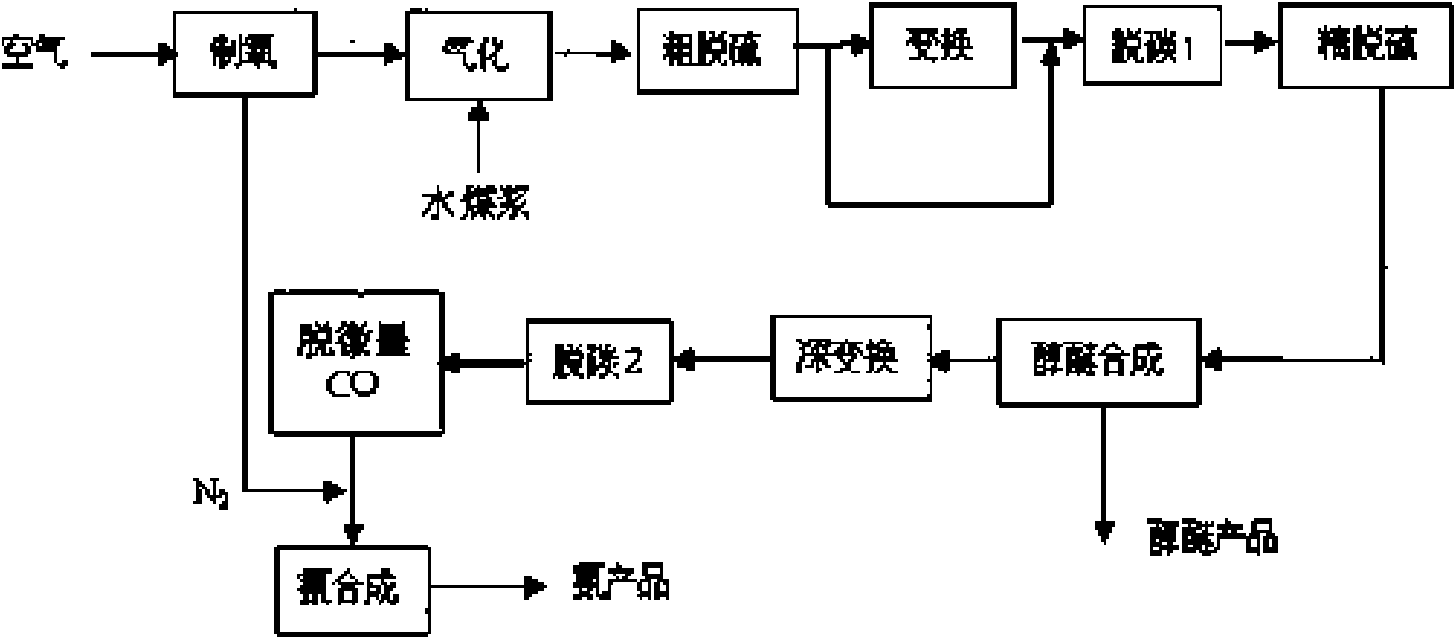

The invention provides a process for producing alcohol-ether hydrazine under medium / low-pressure, which solves the disadvantages of an alcohol-combining process in the prior art. A competitive replacement choice of the process is to serially connect alcohol-ether synthesis and ammonia synthesis into one production line, wherein alcohol-ether synthesis is performed first, and then ammonia synthesis is performed, but alcohol-ether synthesis and ammonia synthesis are relatively independent of the separation of respective products thereof; different proportion and the yield proportion of two products are flexible to regulate; ammonia synthesis does not need the process of additionally adding synthesis gas for compression; and the total pressure is 4 to 15 MPa. The process has the advantages of effectively reducing the power consumption of compression, realizing the flexible proportion regulation of alcohol or ether products, improving the efficiency of the whole technological process, reducing production cost to the utmost extent and laying a foundation for technical progress of the coal chemical industry and large-scale comprehensive development.

Owner:FUZHOU UNIV +1

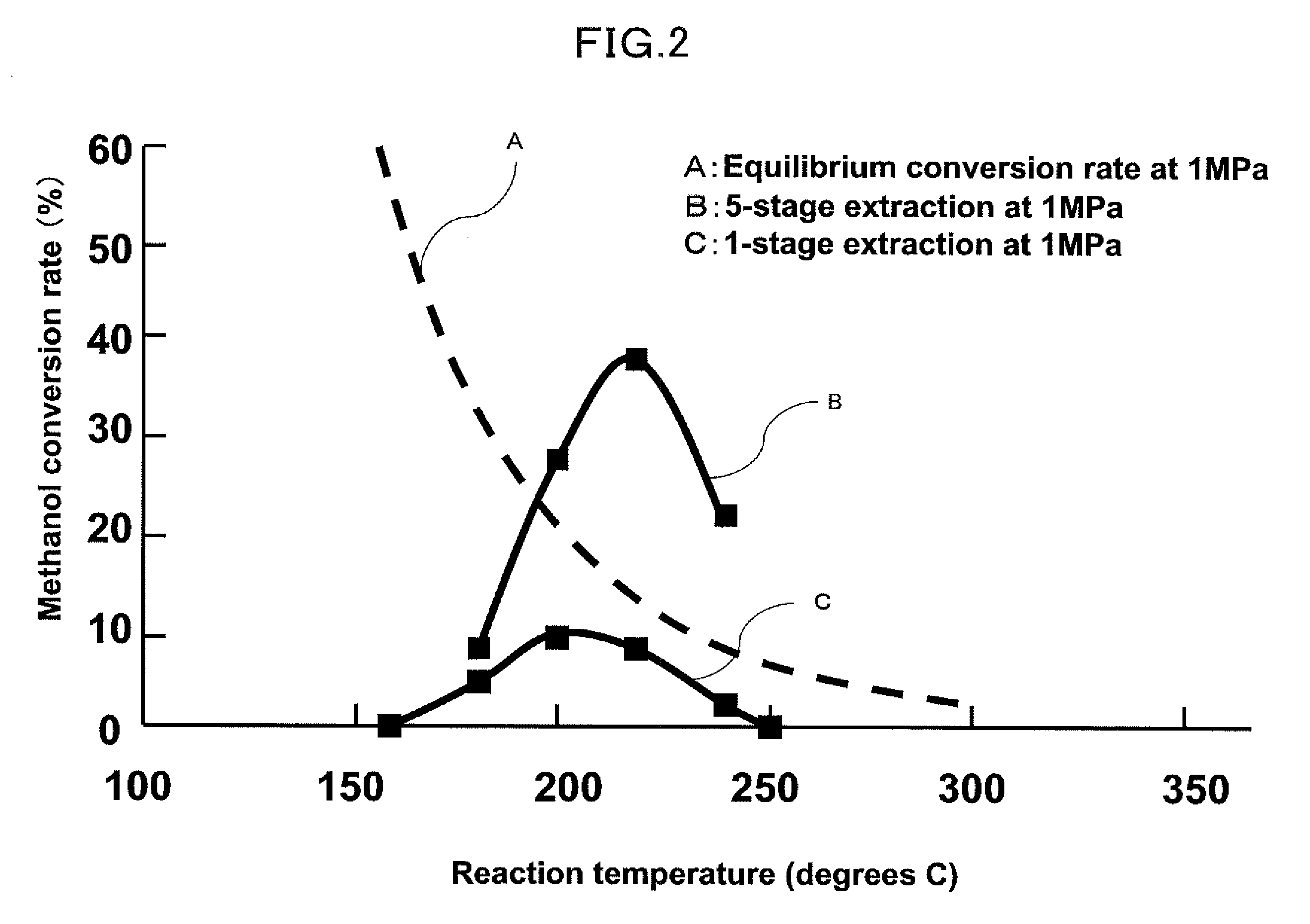

Methanol synthesis catalyst, method for producing such catalyst and method for producing methanol

InactiveCN101384363AReduced activityCheap manufacturingOrganic compound preparationOrganic chemistry methodsHydrogenAlcohol

This catalyst for methanol synthesis, where methanol is synthesized via a formic ester, is a catalyst for methanol synthesis which carries out a reaction under the presence of a starting material gas containing hydrogen and at least either one of carbon monoxide and carbon dioxide, and an alcohol as a solvent, and includes a catalyst containing Cu, Mg, Na, Pd, and an alkali metal formate salt.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

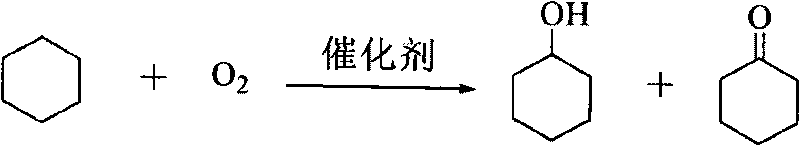

Method for preparing cyclohexanol and cyclohexanone through cyclohexane oxidation

InactiveCN101747142AAchieve reuseActivity unchangedPreparation by oxidation reactionsOrganic compound preparationCyclohexanoneOrganic solvent

The invention discloses a method for preparing cyclohexanol and cyclohexanone through cyclohexane oxidation catalyzed by molecular oxygen. The invention uses the cyclohexane as a reactant, the oxygen as an oxidant and nanoferrite as a catalyst, and any organic solvent or additive are not added during the reaction process. After the reaction, the separation of the catalyst and the product can be realized through simple filtration, the catalyst can be recycled without any loss of the catalytic activity, the conversion rate is over 12%, and the selectivity of the cyclohexanol and cyclohexanone is over 92%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

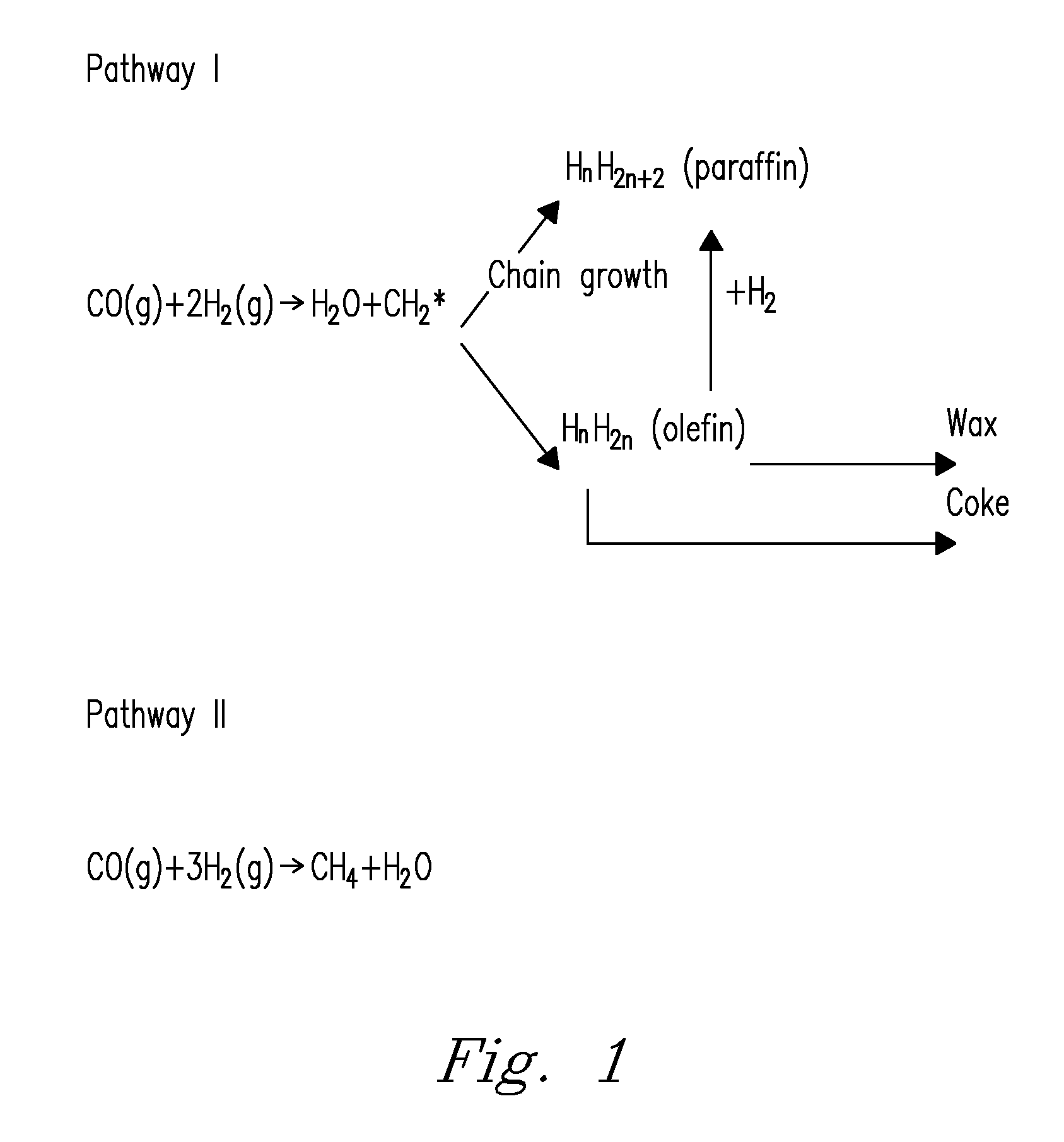

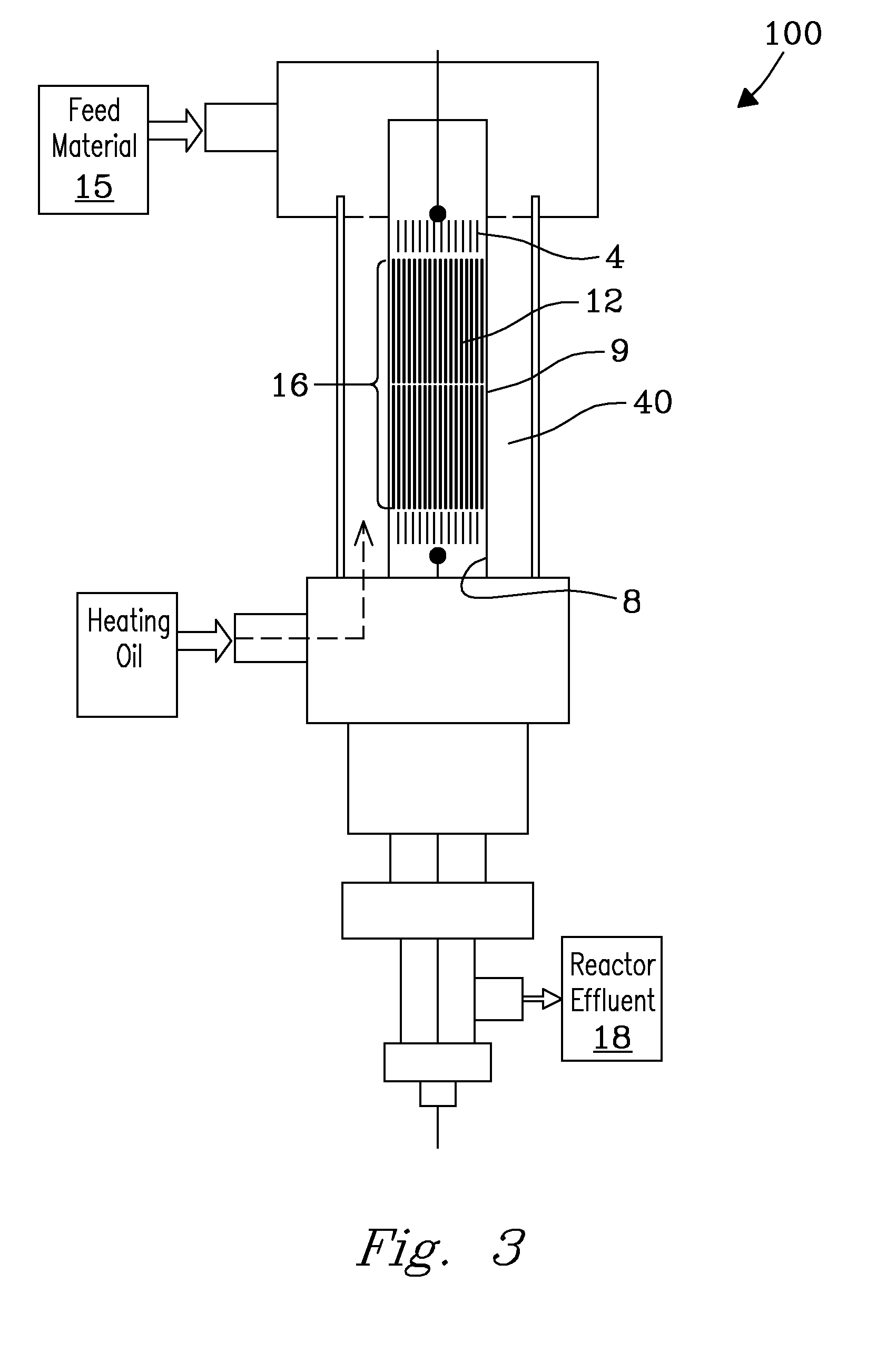

Structured catalyst bed and method for conversion of feed materials to chemical products and liquid fuels

ActiveUS20090215911A1Increase pressureHigh selectivityOrganic compound preparationOxygen compounds preparation by reductionLiquid productReaction rate

The present invention is a structured monolith reactor and method that provides for controlled Fischer-Tropsch (FT) synthesis. The invention controls mass transport limitations leading to higher CO conversion and lower methane selectivity. Over 95 wt % of the total product liquid hydrocarbons obtained from the monolithic catalyst are in the carbon range of C5-C18. The reactor controls readsorption of olefins leading to desired products with a preselected chain length distribution and enhanced overall reaction rate. And, liquid product analysis shows readsorption of olefins is reduced, achieving a narrower FT product distribution.

Owner:BATTELLE MEMORIAL INST

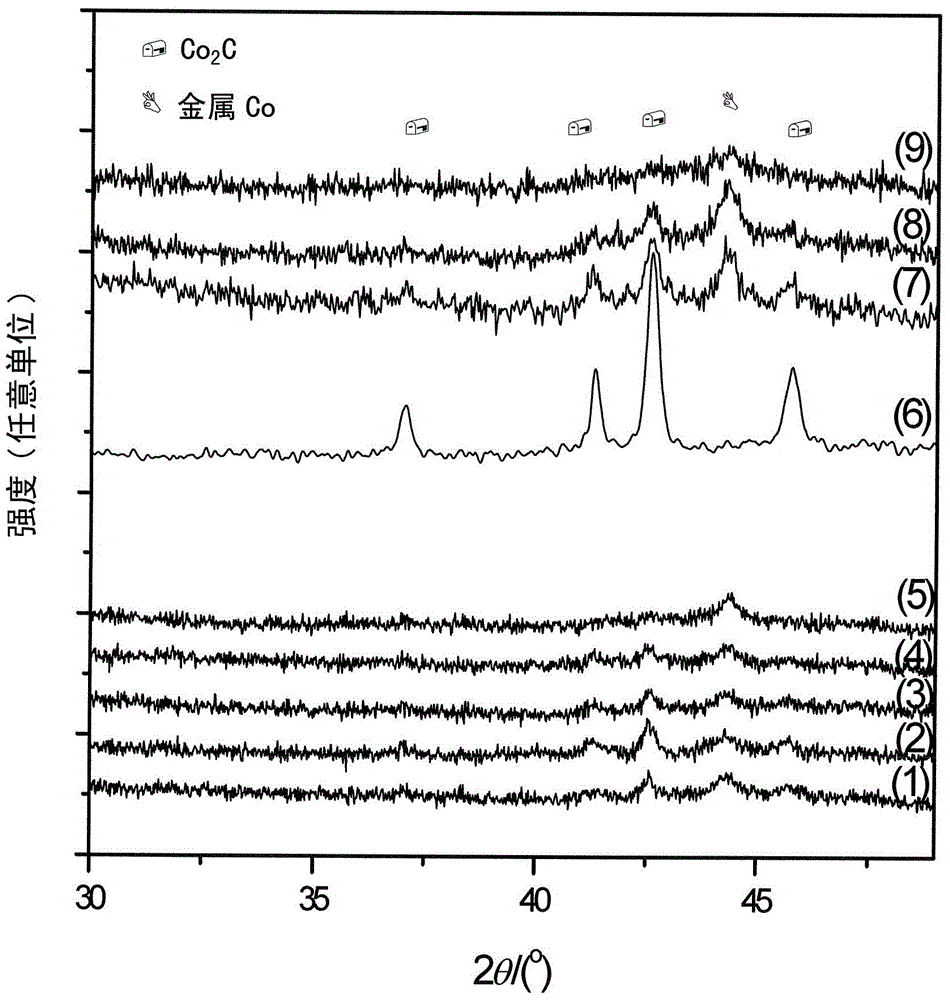

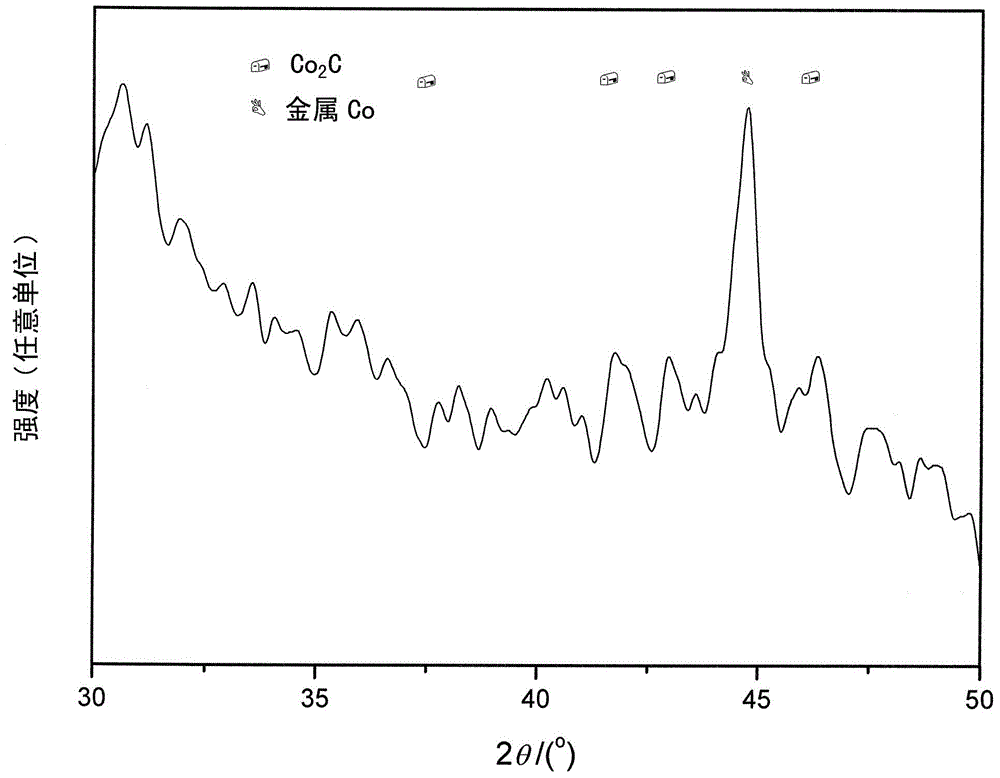

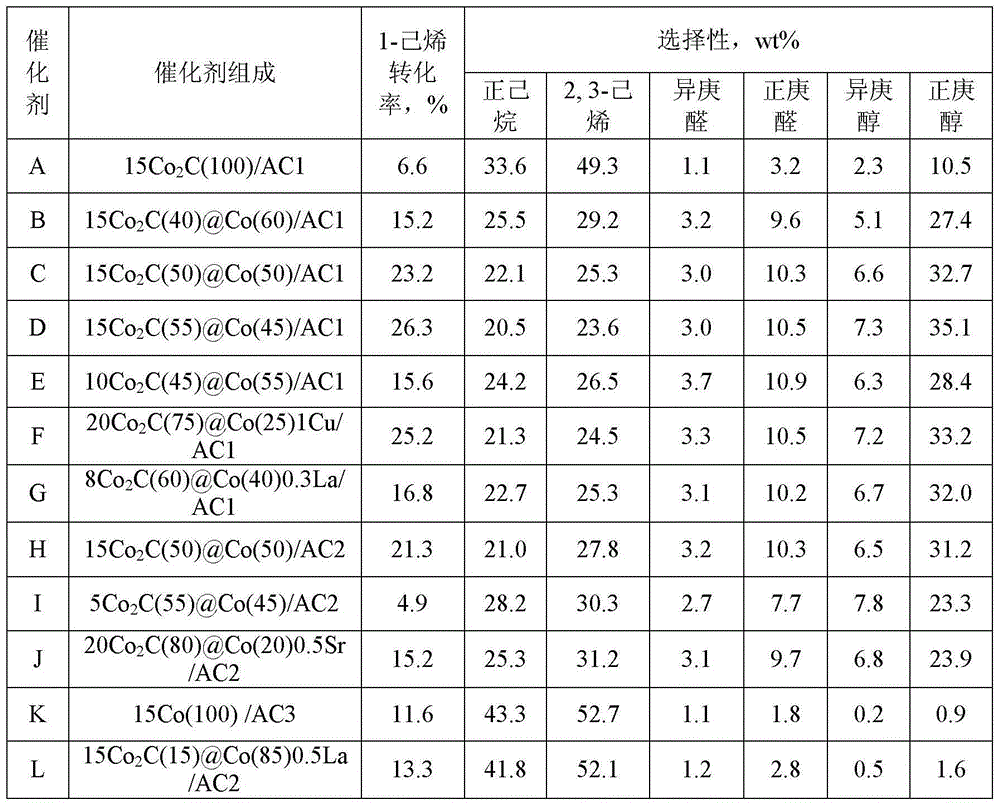

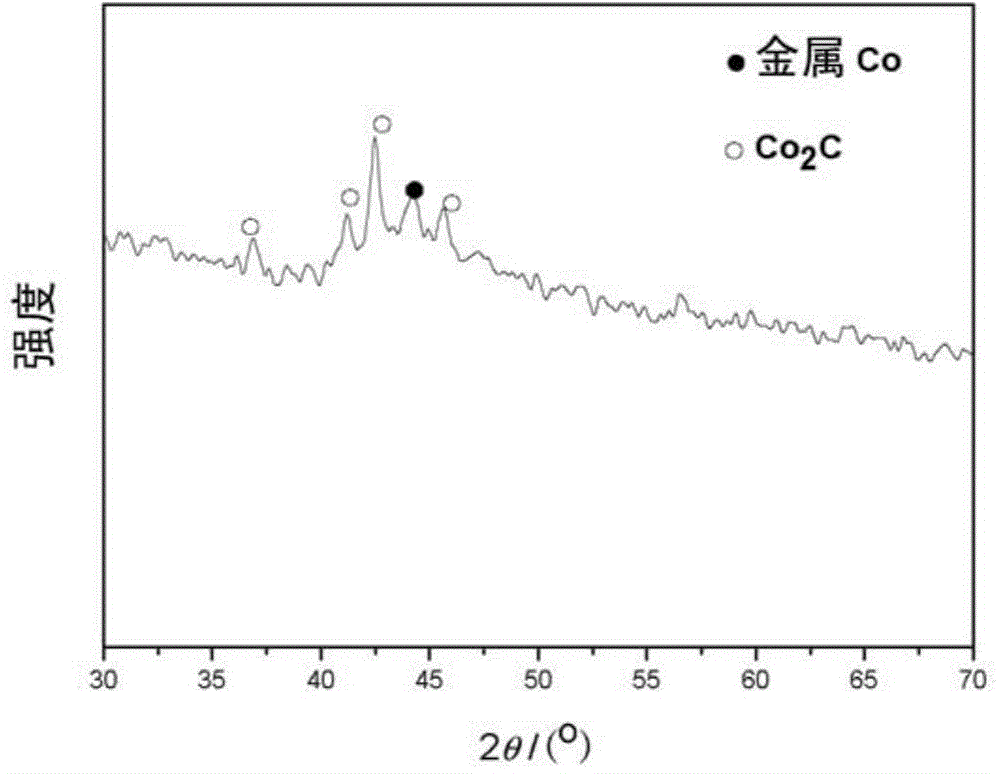

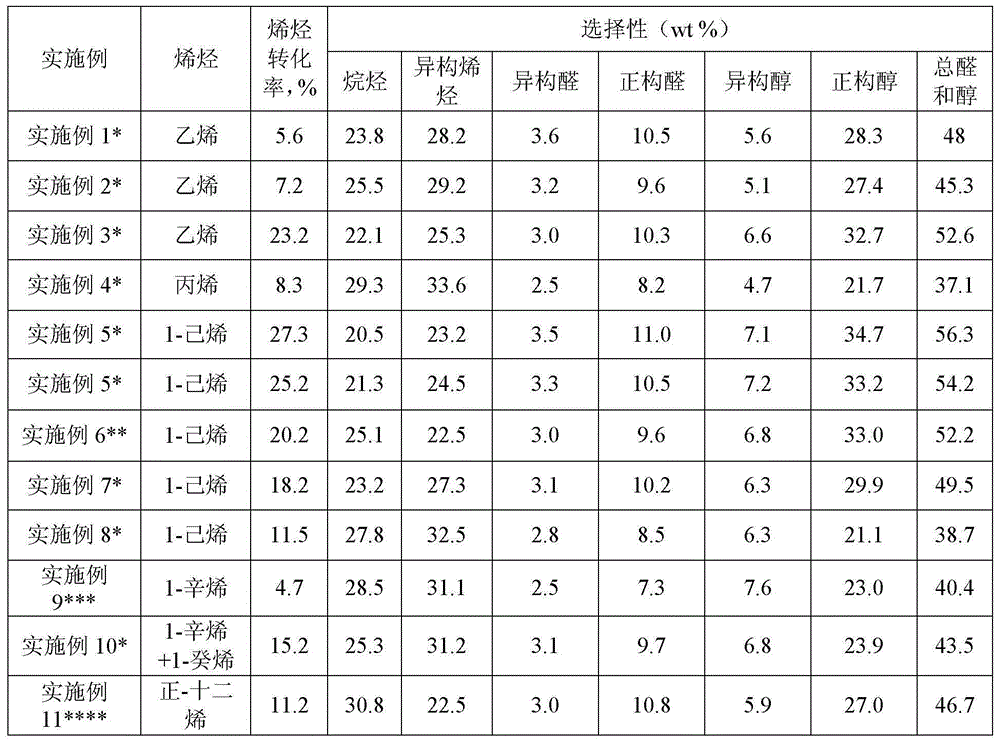

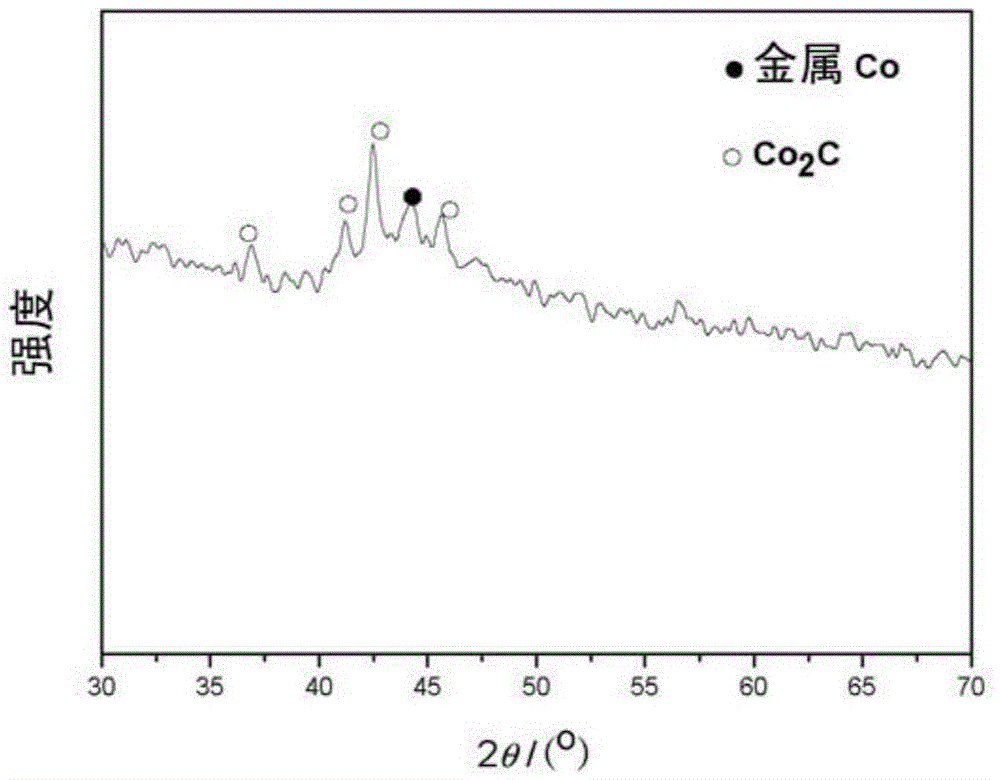

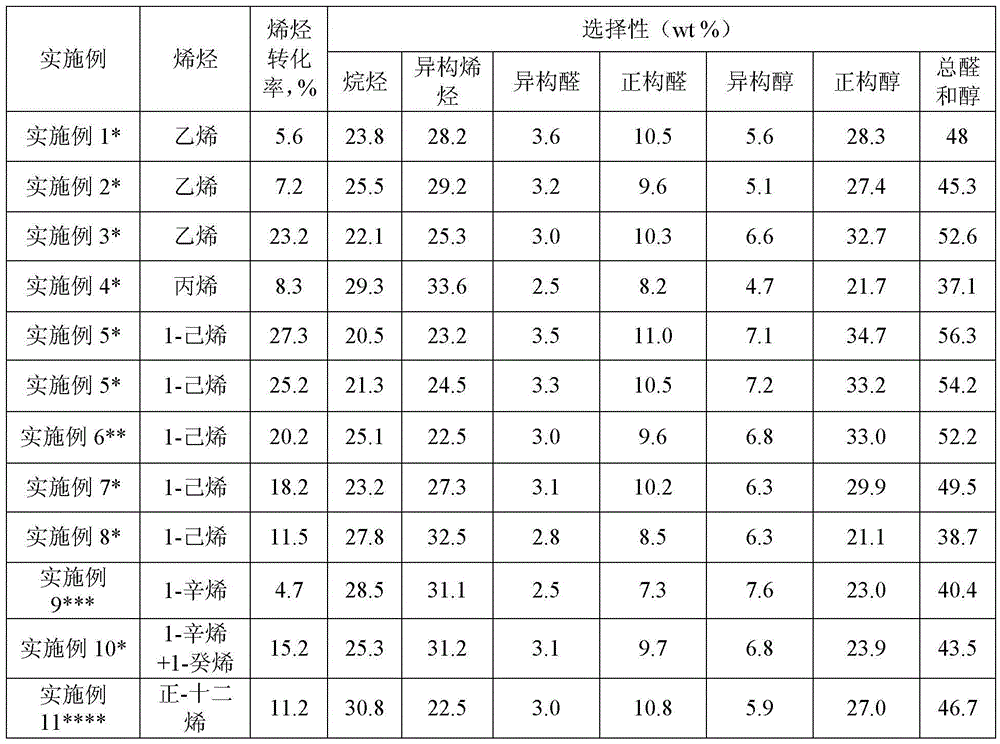

Heterogeneous catalyst for synthesizing aldehydes and alcohols through olefin hydroformylation, and preparation method thereof

ActiveCN104588057AImprove performanceEasy to separatePhysical/chemical process catalystsPreparation by oxo-reaction and reductionInorganic saltsAlcohol

The present invention provides a heterogeneous catalyst for synthesizing aldehydes and alcohols through olefin hydroformylation, and a preparation method thereof. The catalyst is a loaded heterogeneous catalyst and comprises a main active component, a carrier and an optionally selected auxiliary agent, wherein the main active component is Co2C or a compound of Co2C and a metal Co, the Co2C weight content in the compound is 40-100%, the carrier is active carbon, the auxiliary agent is one or more selected from Cu, La, Ce, Li and Sr, and the olefin is C2-C18 alpha-olefin. The preparation method comprises: adopting an impregnation method to impregnate the main active component and the soluble inorganic salt solution of the optionally selected auxiliary agent onto the active carbon carrier, drying, calcinating, reducing, and carbonizing to obtain the heterogeneous catalyst. The heterogeneous catalyst of the present invention has characteristics of high hydroformylation activity and selectivity, easy separation from the product, avoidance of the problems of catalyst and production separation and recycling caused by the routine use of the homogeneous catalyst, and broad industrial application prospects.

Owner:中科榆林能源技术运营有限责任公司

Aluminium base slurried catalyst and preparation thereof

InactiveCN101264448ALow priceReduce moistureOxygen compounds by oxo-reactionMetal/metal-oxides/metal-hydroxide catalystsSlurryDimethyl ether

The invention relates to an aluminum base slurry catalyst and a preparation method thereof, belonging to the technical field of catalyst preparation, in particular to a slurry catalyst which adopts AlOOH as aluminum source and directly synthesizes the methanol and dimethyl ether for slurry bed from solution to serosity and the preparation method thereof; in the catalyst, Al exists in the form of AlOOH. The aluminum base slurry catalyst has the advantages of reducing material cost from source, greatly reducing water content in catalyst precursor, greatly decreasing the size of the production equipment, improving efficiency of the equipment and facilitating the industrial production.

Owner:TAIYUAN UNIV OF TECH

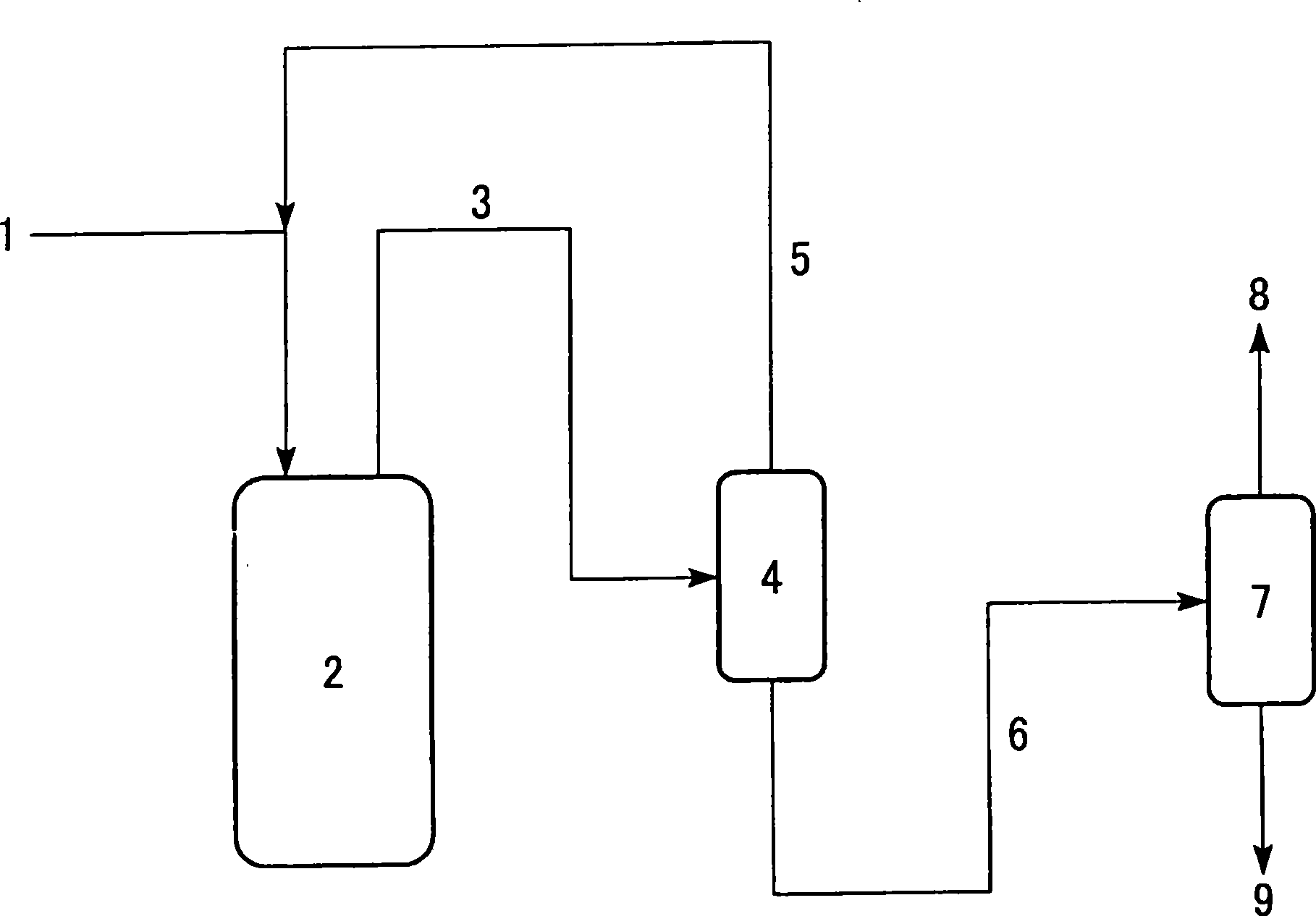

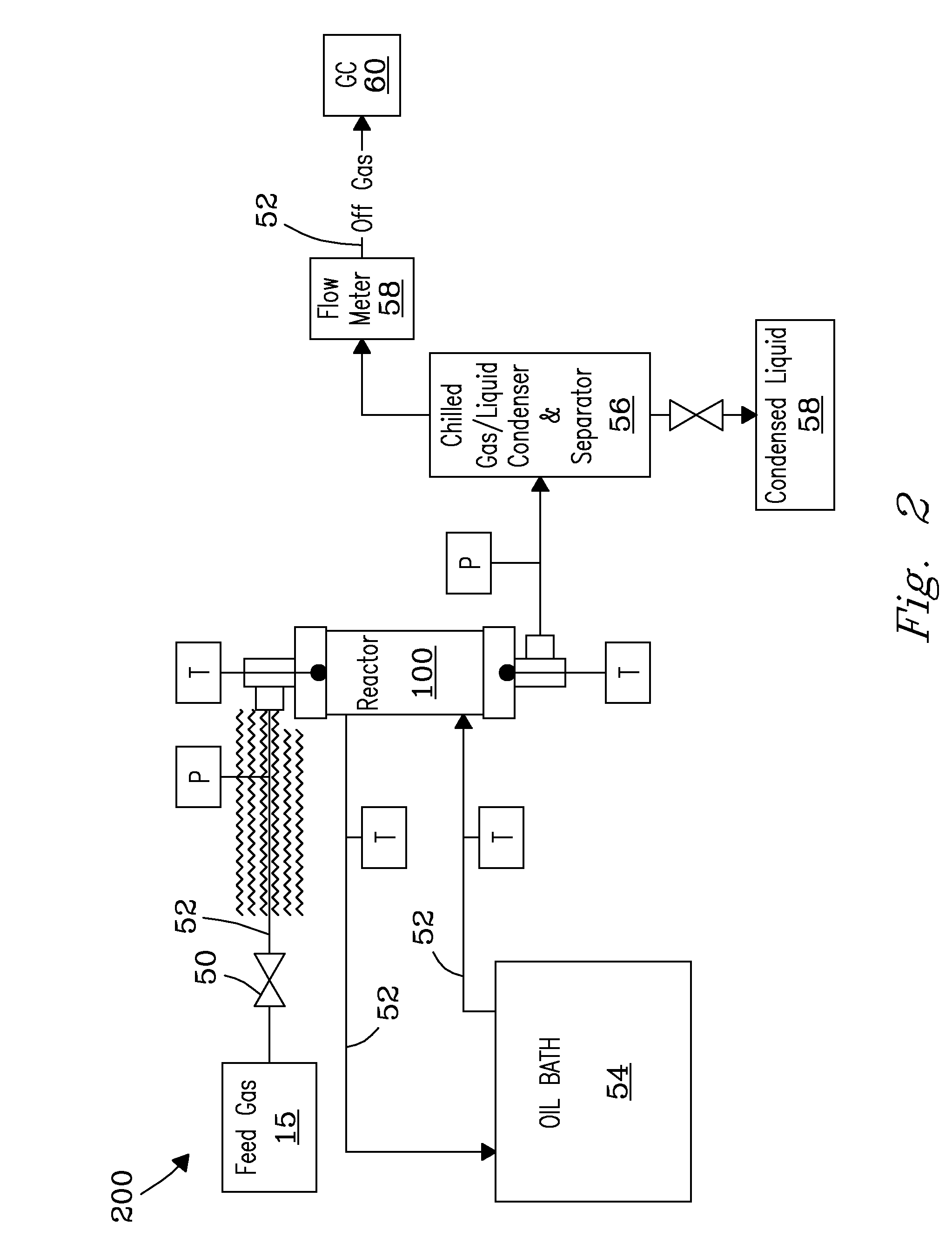

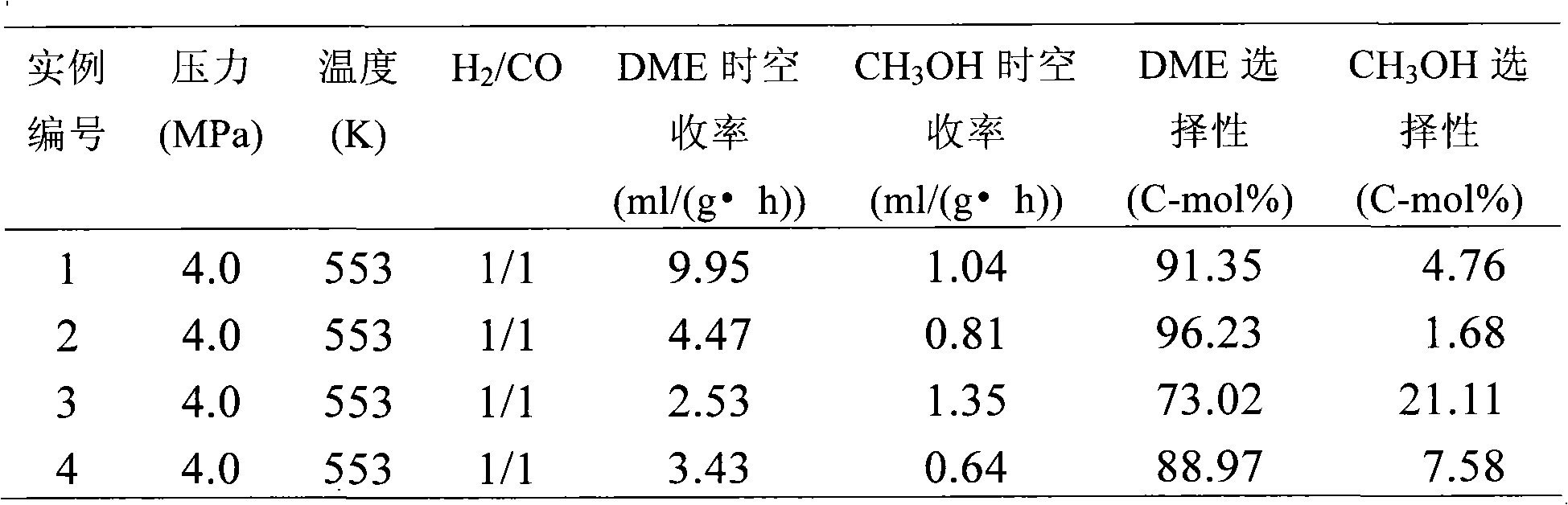

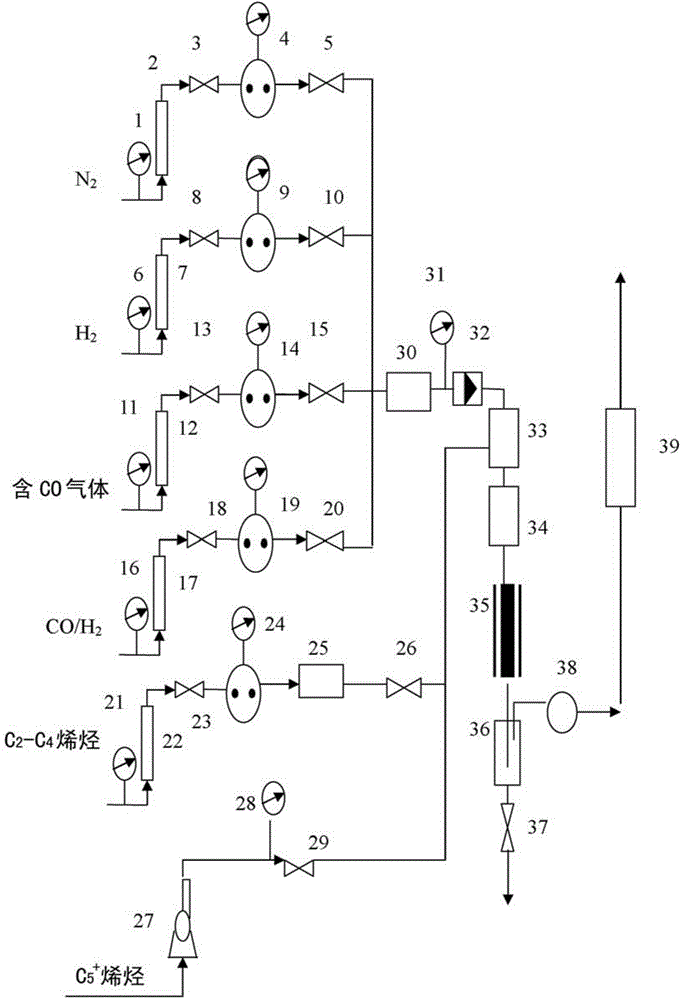

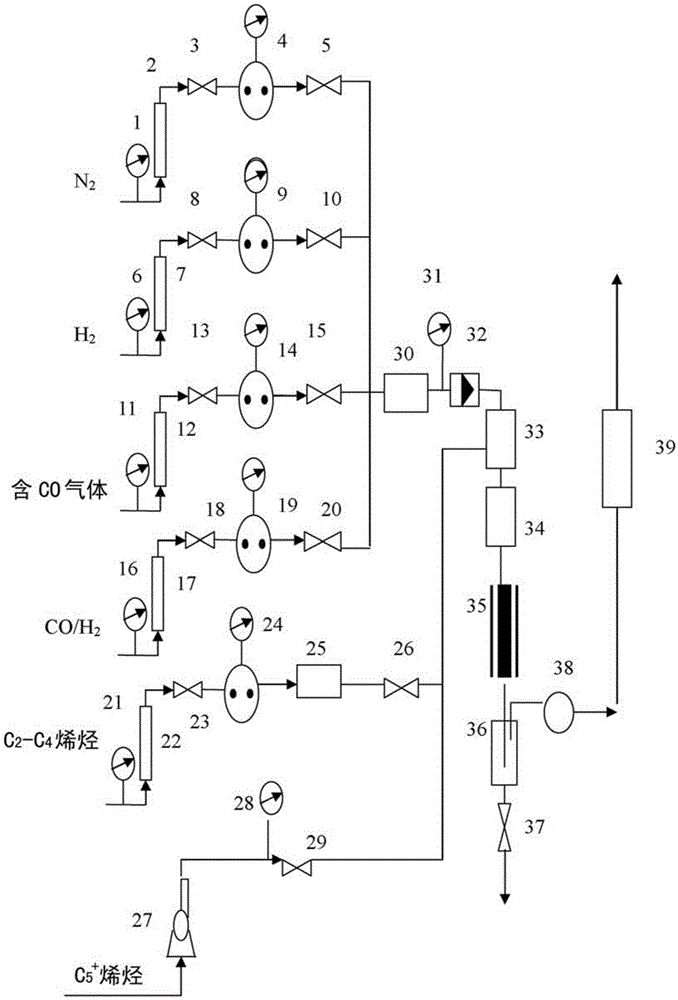

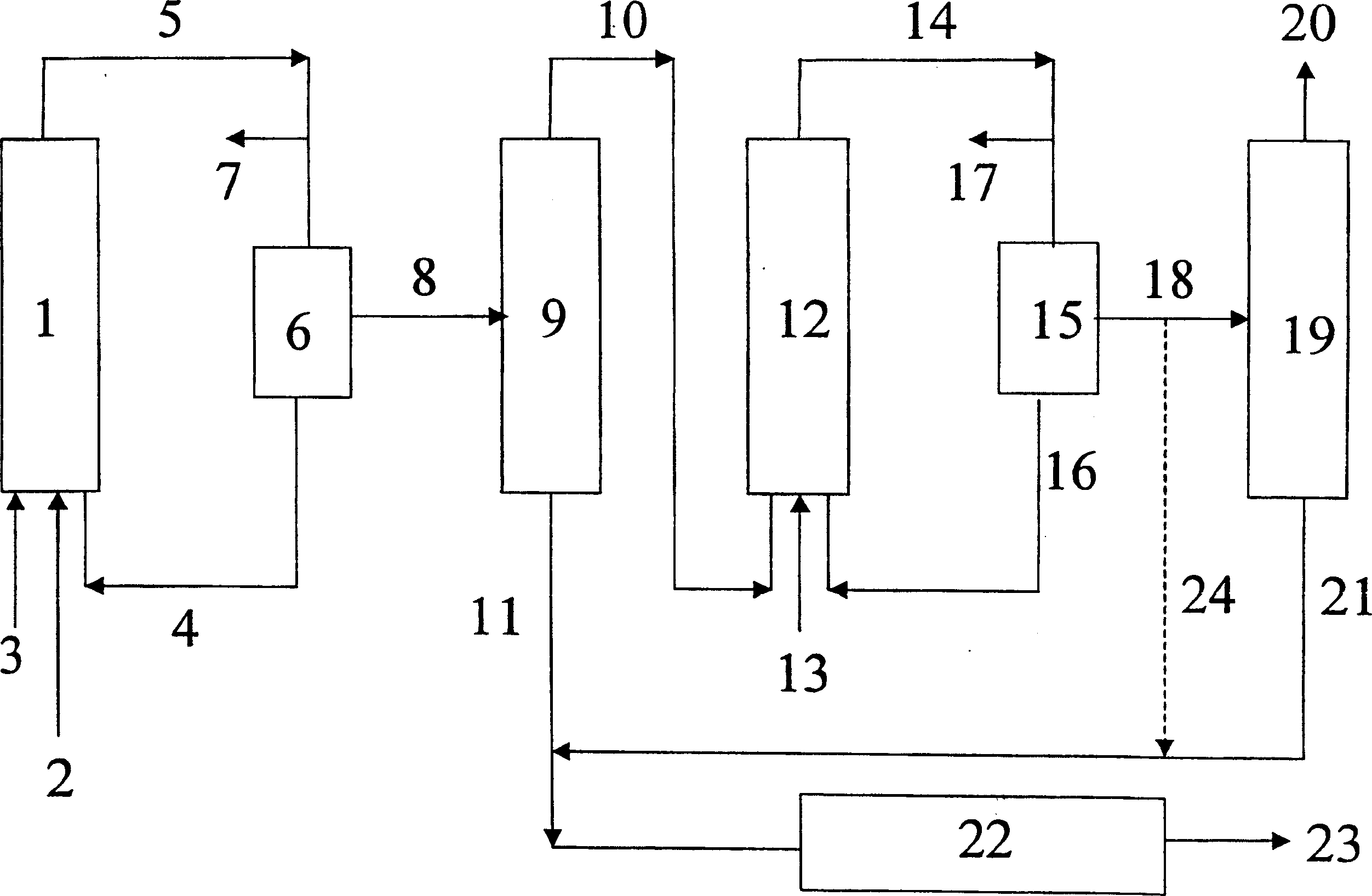

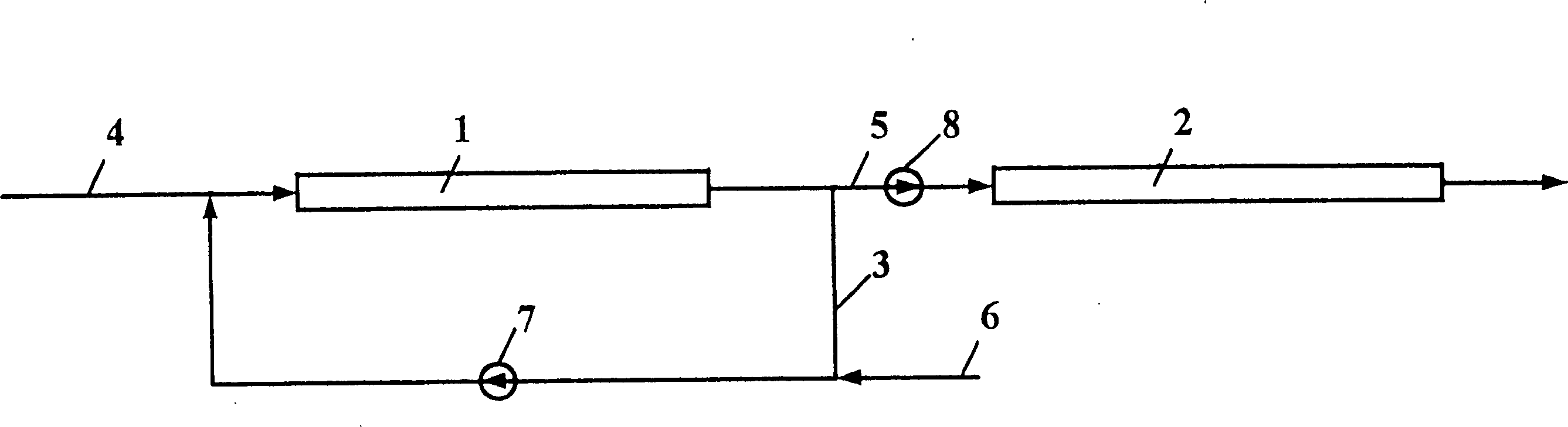

Heterogeneous catalysis method for synthesizing aldehydes and alcohols through olefin hydroformylation, and apparatus thereof

ActiveCN104591960ASolve outstanding problems that are difficult to separateSimple processPhysical/chemical process catalystsOrganic compound preparationSyngasAlcohol

The present invention relates to a heterogeneous catalysis process for synthesizing aldehydes and alcohols through olefin hydroformylation, and an apparatus thereof. More particularly, the present invention provides a heterogeneous catalysis method for synthesizing aldehydes and alcohols through olefin hydroformylation, wherein the method comprises that olefin and synthesis gas are continuously fed into a reactor to be in a hydroformylation reaction in the presence of a loaded heterogeneous catalyst, and the generated products such as aldehydes and alcohols continuously flow out from the reactor so as to achieve the separation from the catalyst and the continuous production. The present invention further provides the apparatus for the method, wherein the apparatus comprises the reactor, a pre-heater arranged on the upstream of the reactor and connected with the reactor, a mixer arranged on the upstream of the pre-heater and connected with the pre-heater, and a collecting tank arranged on downstream of the reactor and connected with the reactor. The process and the apparatus of the present invention have advantages of excellent hydroformylation performance, easy product and catalyst separation, and simple process, and further have industrial prospects.

Owner:中科榆林能源技术运营有限责任公司

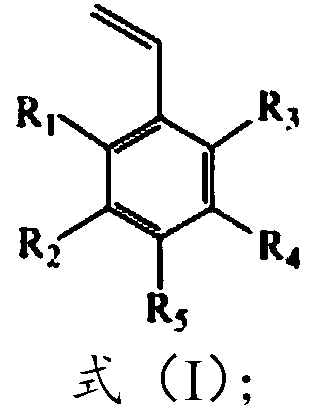

Method for producing alkyl-substituted butenols

Alkyl-substituted butenols having the formula (I):R1—CH2—CH═CR2—CH2OH (I)wherein R1 is a saturated or olefinically unsaturated alkyl or cycloalkyl group having from 4 to 16 carbon atoms and wherein R1 is optionally substituted by an alkyl, cycloalkyl, aryl or alkaryl having up to 12 carbon atoms; R2 is hydrogen or an alkyl group having from 1 to about 6 carbon atoms are produced by a process which comprises: (1) reacting an aldehyde of the formula (II):R1—CH2—CHO (II)wherein R1 has the same meaning as in formula (I), with the corresponding lower aldehyde to form an unsaturated aldehyde in an inert organic solvent; (2) continuously contacting an optionally calcined copper / zinc catalyst with the unsaturated aldehyde under isothermal conditions at temperatures of from about 45 to about 60° C. and under a hydrogen pressure of from 1 to about 300 bar.

Owner:KAO CORP

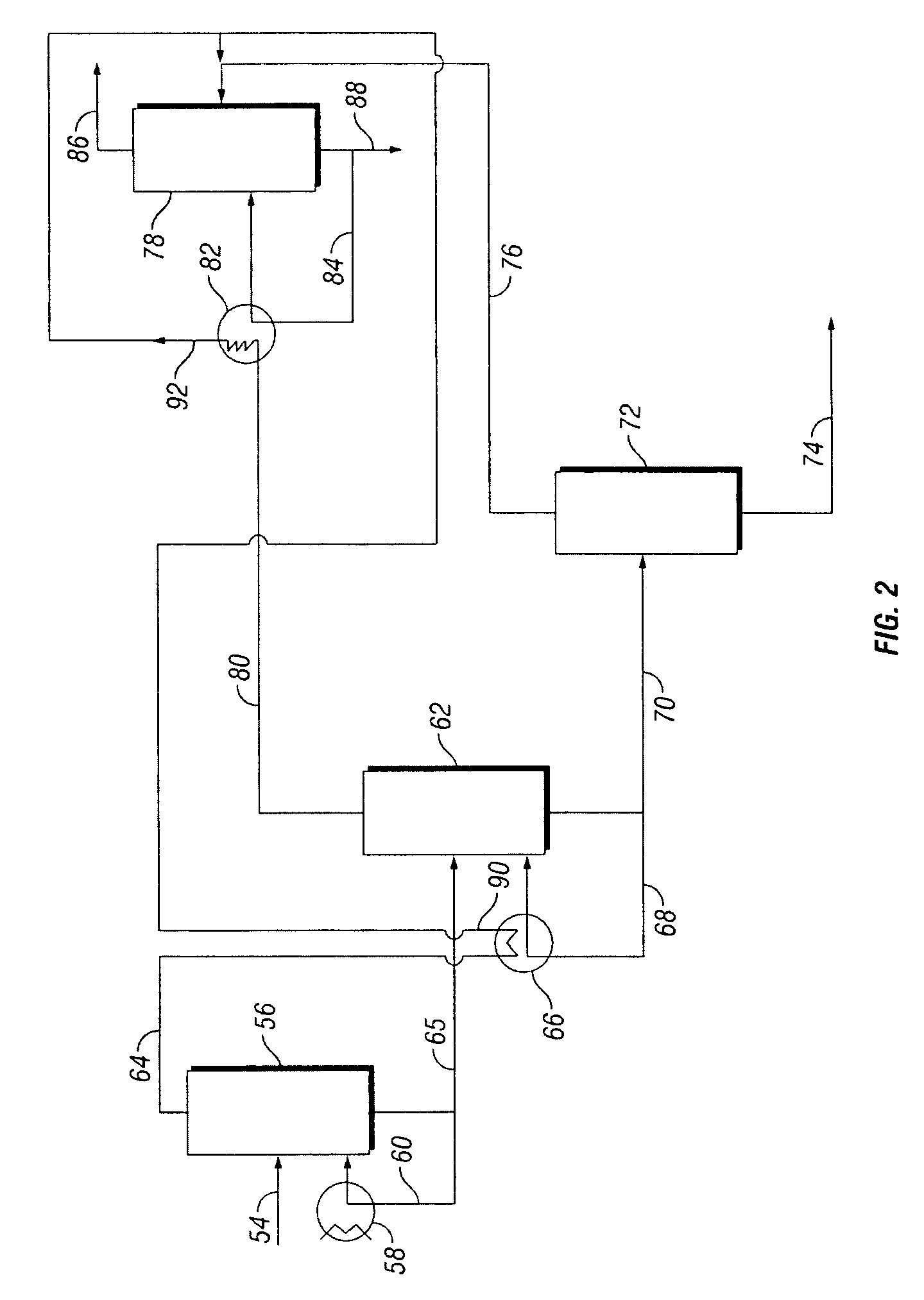

Process for preparing 1,3-propanediol

The invention provides a process for preparing 1,3-alkanediols, such as 1,3-propanediol (PDO), from 3-hydroxyaldehydes, such as 3-hydroxypropanal (HPA), comprising providing a mixture of 3-hydroxyaldehydes in an organic solvent; extracting into an aqueous liquid a major portion of the 3-hydroxyaldehydes to provide an aqueous phase comprising 3-hydroxyaldehydes in greater concentration than the concentration of 3-hydroxyaldehydes in the 3-hydroxyaldehyde mixture, and an organic phase; separating the aqueous phase from the organic phase; contacting the aqueous phase with hydrogen in the presence of a hydrogenation catalyst to provide a hydrogenation product mixture comprising 1,3-alkanediols and water; separating water from the 1,3-alkanediols using a multi-effect evaporation scheme; recycling water containing about 50 wt % or less 1,3-propanediol based upon the total amount of 1,3-propanediol and water to the extraction stage; and recovering 1,3-alkanediols.

Owner:SHELL OIL CO

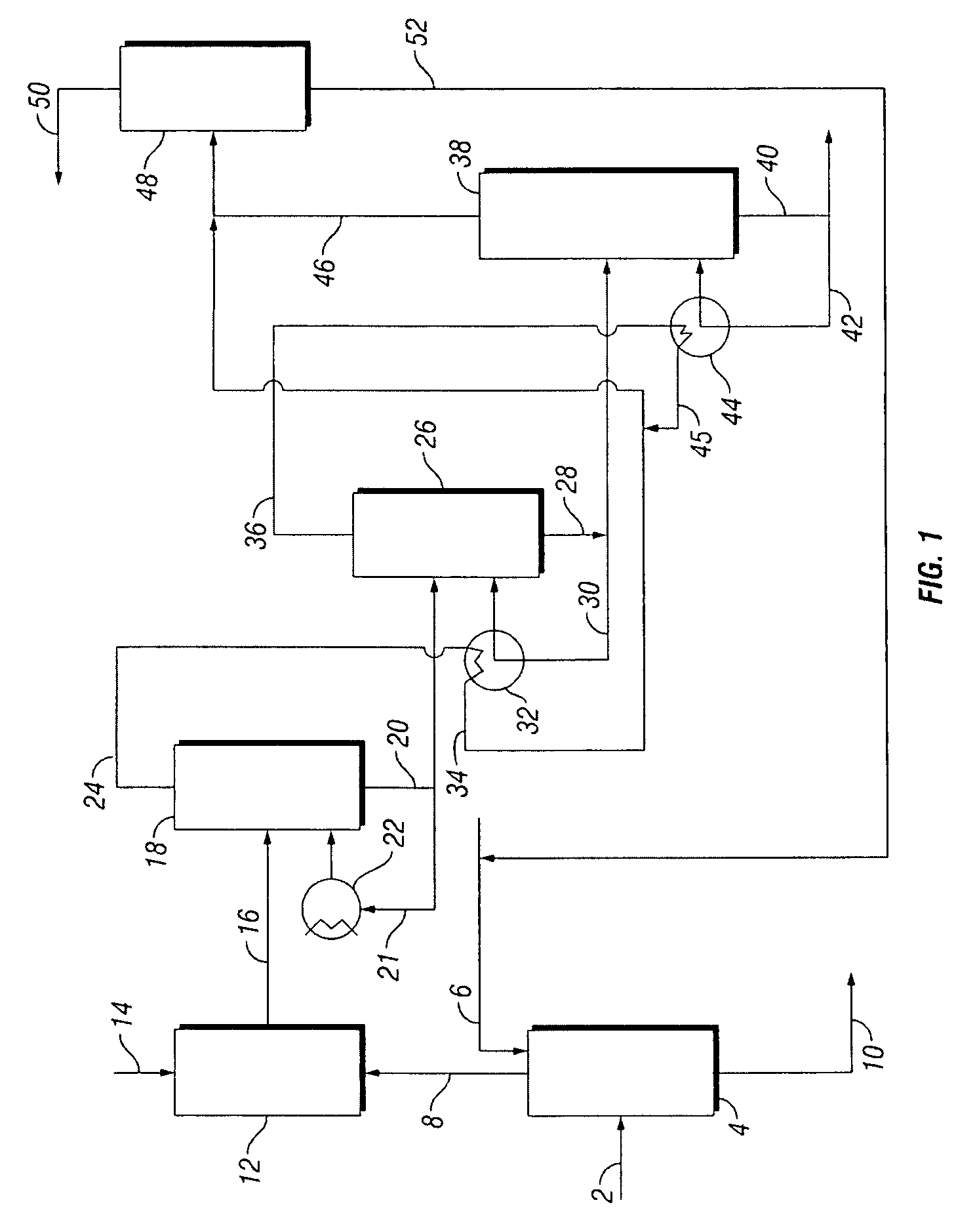

Process for coproduction of normal butanol and isobutyraldehyde

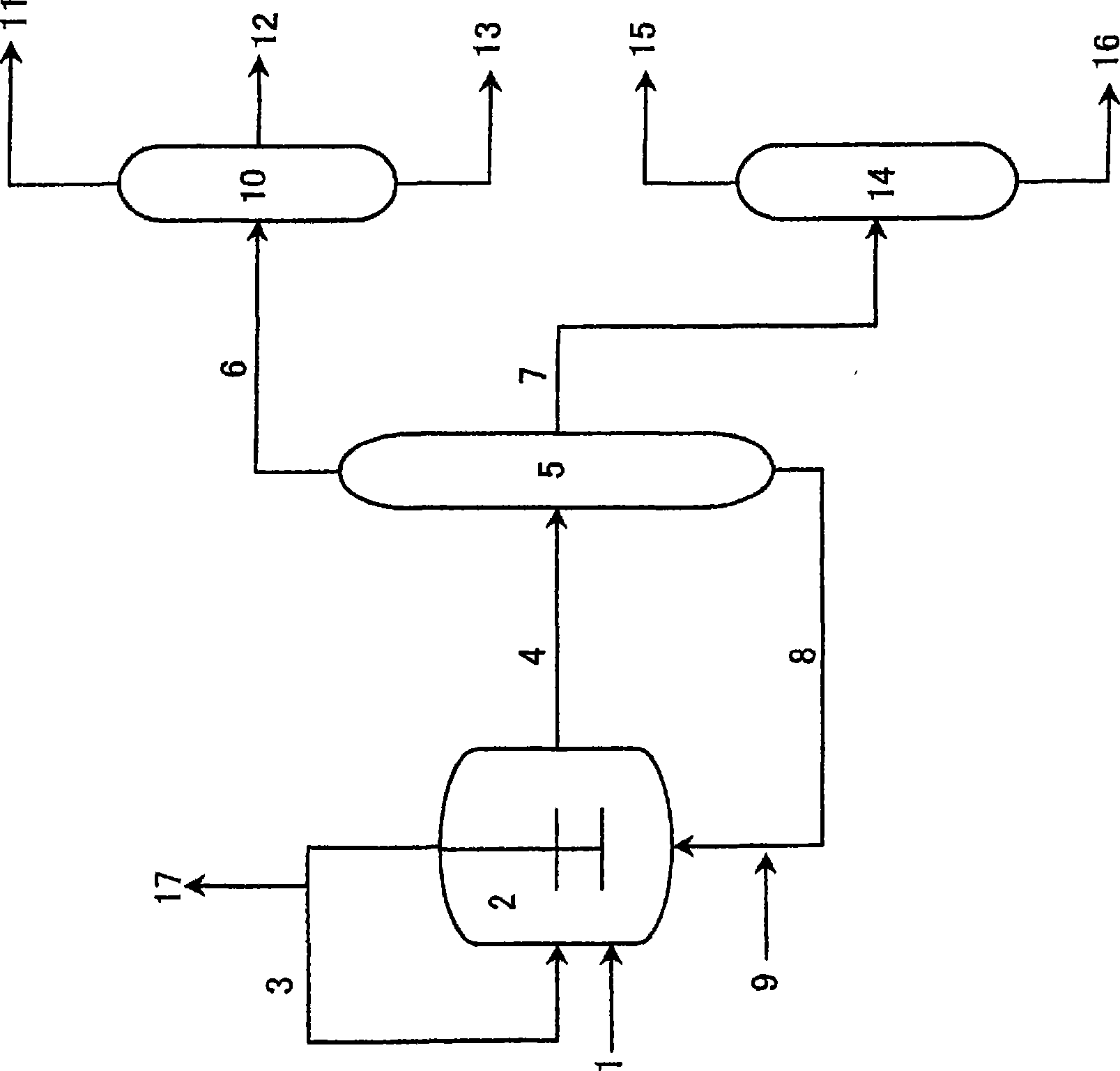

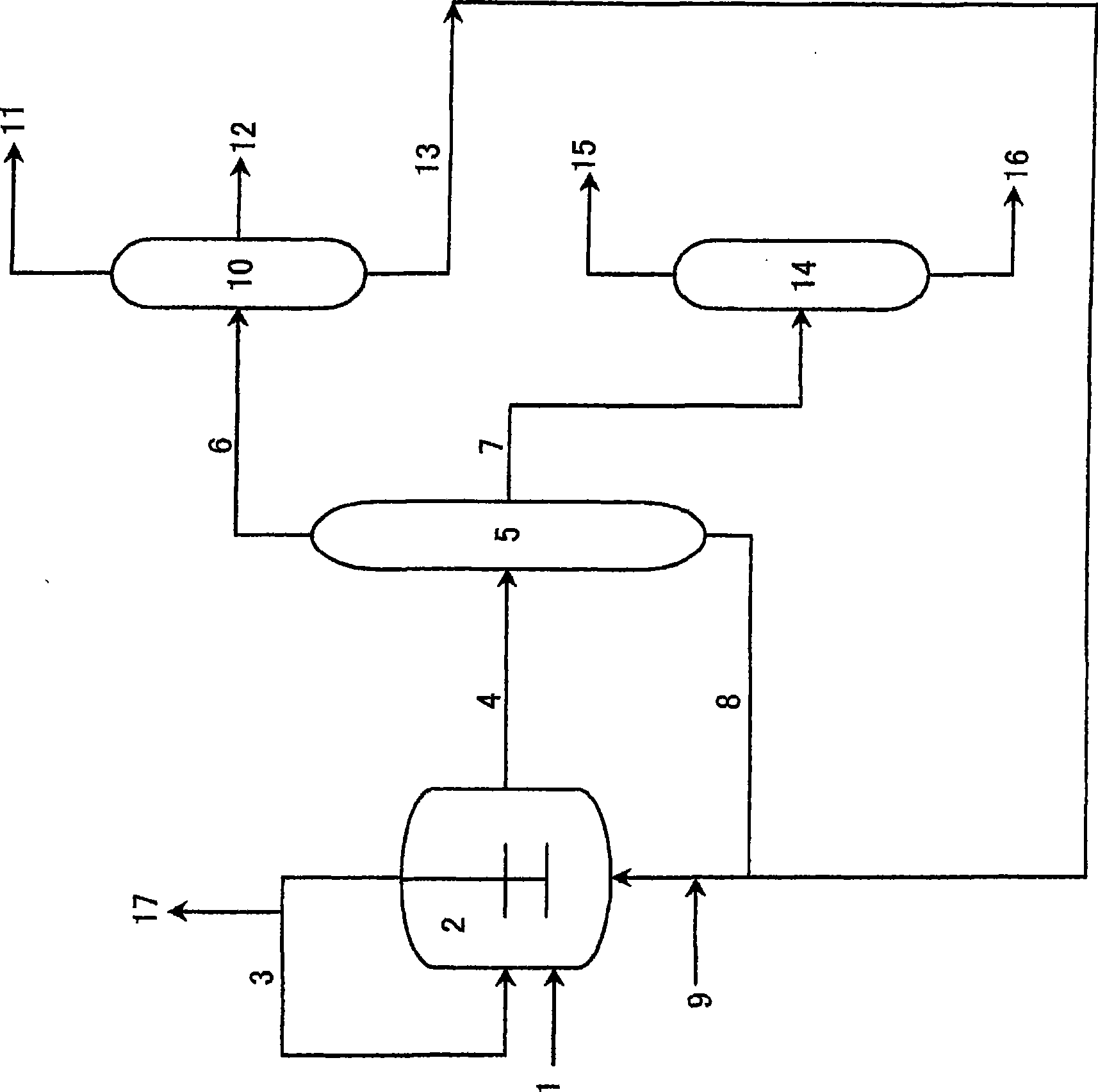

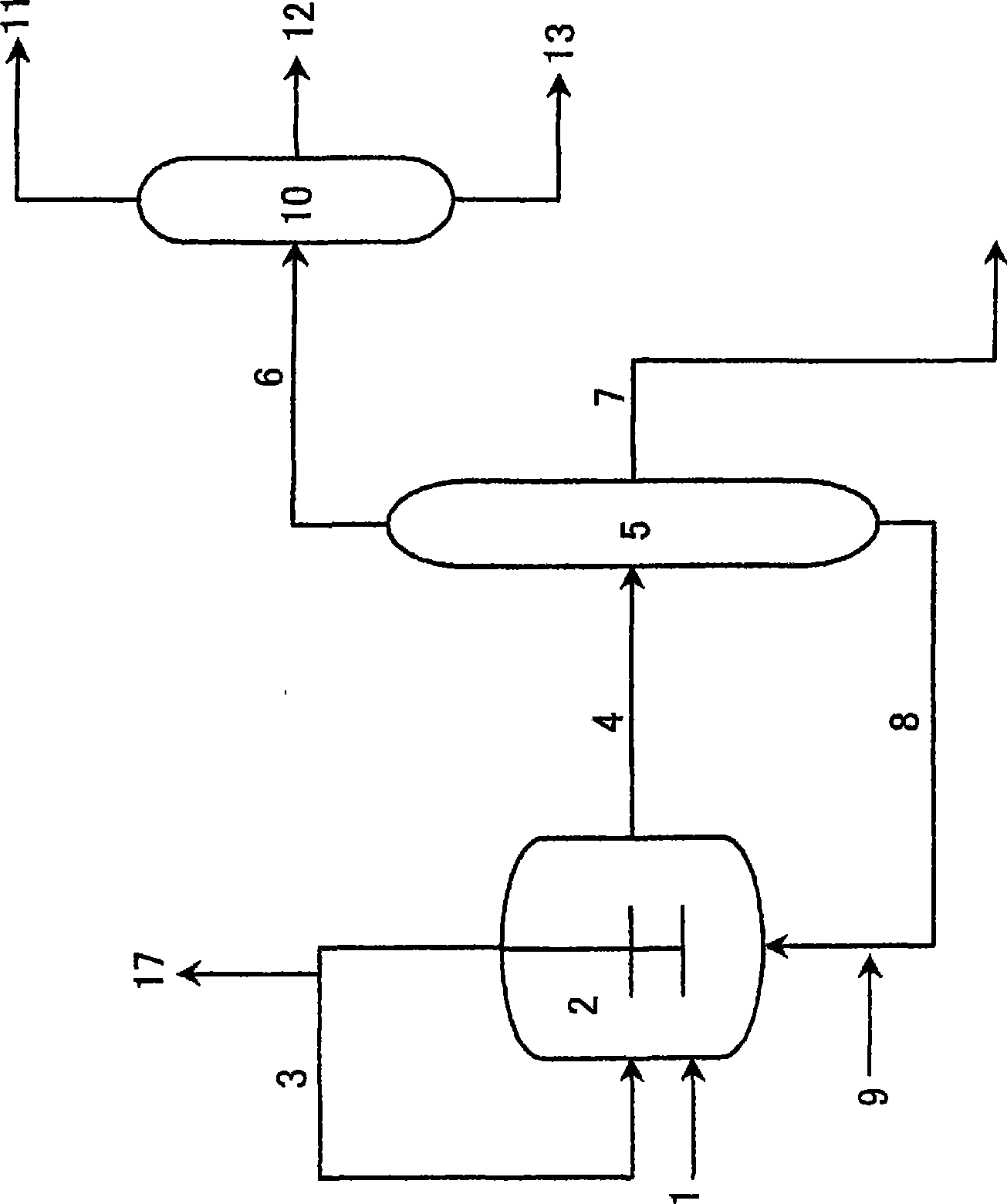

The invention relates to a process for the coproduction of normal butanol and isobutyraldehyde by reacting propylene with hydrogen and carbon monoxide. The process comprises the step (A) of reacting propylene with hydrogen and carbon monoxide in a reactor (2) in the presence of a catalyst containing a compound of a Group 8, 9 or 10 metal element of the periodic table, the step (B) of withdrawing an overhead product containing normal butyraldehyde and so on and a sidestream containing isobutanol and so on from the reaction product stream with a separator (the first distilling column) (5), and the step (C) of separating the overhead product into normal butyraldehyde and isobutyraldehyde by fractional distillation with a separator (the second distilling column) (10) while separating the sidestream into isobutanol and normal butanol by fractional distillation with a separator (the third distilling column) (14), and withdrawing them separately.

Owner:MITSUBISHI RAYON CO LTD

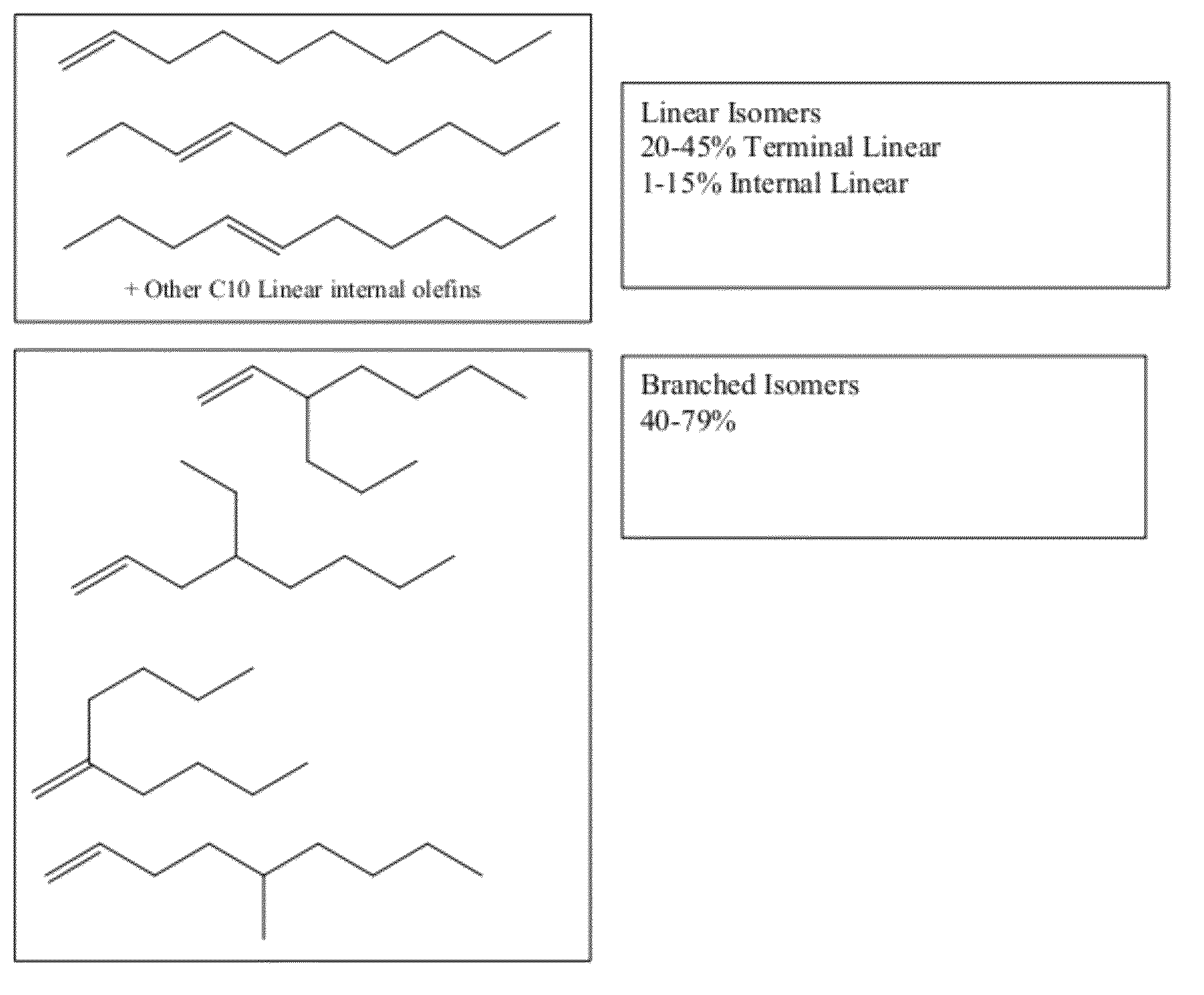

Functionalized long-chain olefin mixtures and uses therefor

ActiveUS8211949B2Preparation by oxo-reaction and reductionSurface-active detergent compositionsSulfonateAlcohol

Novel mixtures of long-chain (C10-C20) olefins are functionalized by conversion to aldehydes using an OXO process, or to sulfates, sulfonates, sulfones, sulfides, or sulfoxides by direct sulfonation. The aldehydes may then be hydrogenated to form alcohols, or aminated to form amines or amides. The olefins starting mixture may be acquired as a byproduct of the tetramerization of ethylene in the presence of certain chromium-containing tetramerization catalysts. The functionalized mixtures, and derivatives prepared therefrom such as alkoxylates prepared from the alcohols, may be useful as surfactants that may offer improved performance in many applications, while their preparation based on a byproduct mixture reduces their cost and also reduces waste-handling issues for this non-targeted stream.

Owner:DOW GLOBAL TECH LLC

Simple low-pressure fischer-tropsch process

InactiveUS20090111900A1Improve efficiencyImprove cooling effectOrganic compound preparationOxygen compounds preparation by reductionRheniumWax

A process for combing carbon monoxide and hydrogen to form liquid fuels such as diesels, and / or waxes, in a single pass fixed bed reactor, at an operation pressure less than 200 psig. The reactor uses a catalyst with a metallic cobalt loading greater than 5% by weight and a rhenium loading of less than 2% by weight, on an alumina support.

Owner:CANADA CHEM CORP

Phosphide Catalyst for Syngas Conversion and the Production Method and Use thereof

InactiveUS20140018455A1High activityHigh selectivityHydrocarbon from carbon oxidesOrganic compound preparationSyngasActive component

This invention provides a phosphide catalyst for syngas conversion and the production method and use thereof, more specifically, to a catalyst for converting a syngas raw material into oxygenates, comprising one or more metallic Fe, Co, Ni and their phosphides, the production method of the catalyst and its use in the reaction of converting a syngas raw material into hydrocarbons and oxygenates. According to the invention, a catalyst for converting H2 / CO into hydrocarbons and oxygenates, supported by SiO2 or Al2O3 and comprising one or more metallic Fe, Co, Ni and their phosphides under certain reaction temperatures and pressures is provided. The catalysts are consisted of two parts of an active component and a support. The active component is a mixture consisted of one or more of metallic Fe, Co, Ni and their phosphides. The support is selected from SiO2 or Al2O3. In a fix-bed or slurry bed reactor, H2 / CO can be converted into oxygenates having two carbons or more and hydrocarbons with high activity and high selectivity, under certain reaction temperatures and pressures and the action of the catalyst in the invention.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

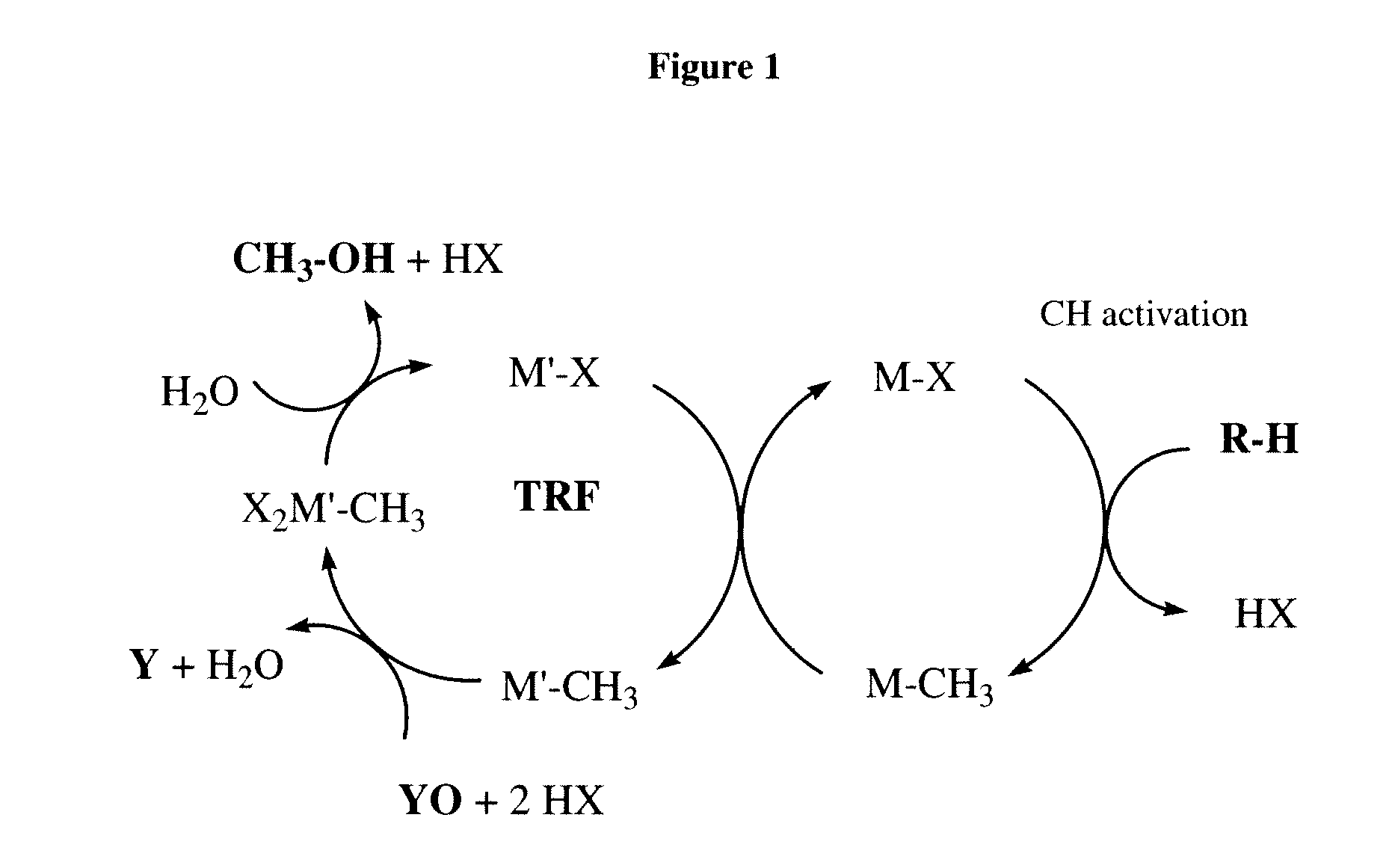

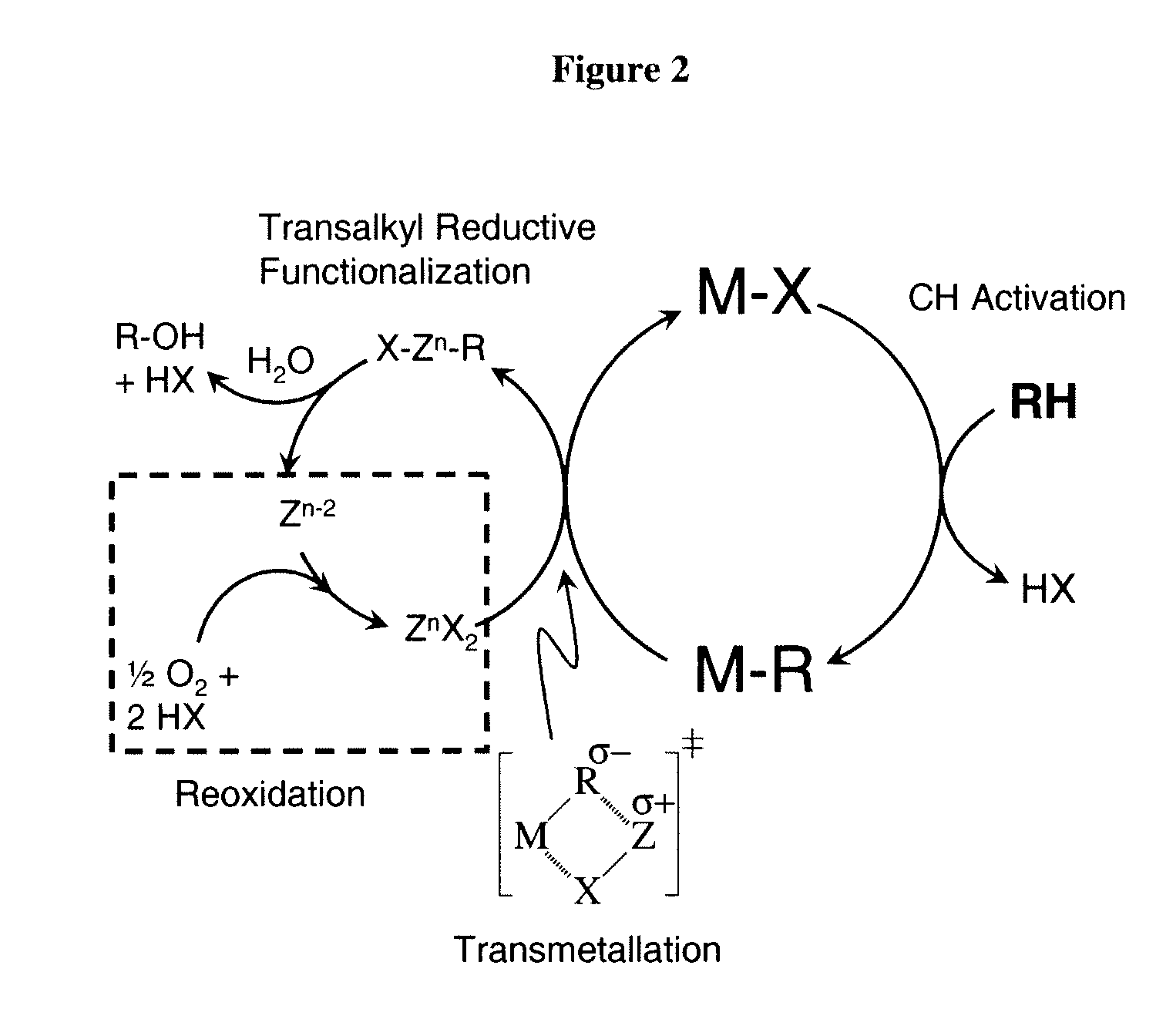

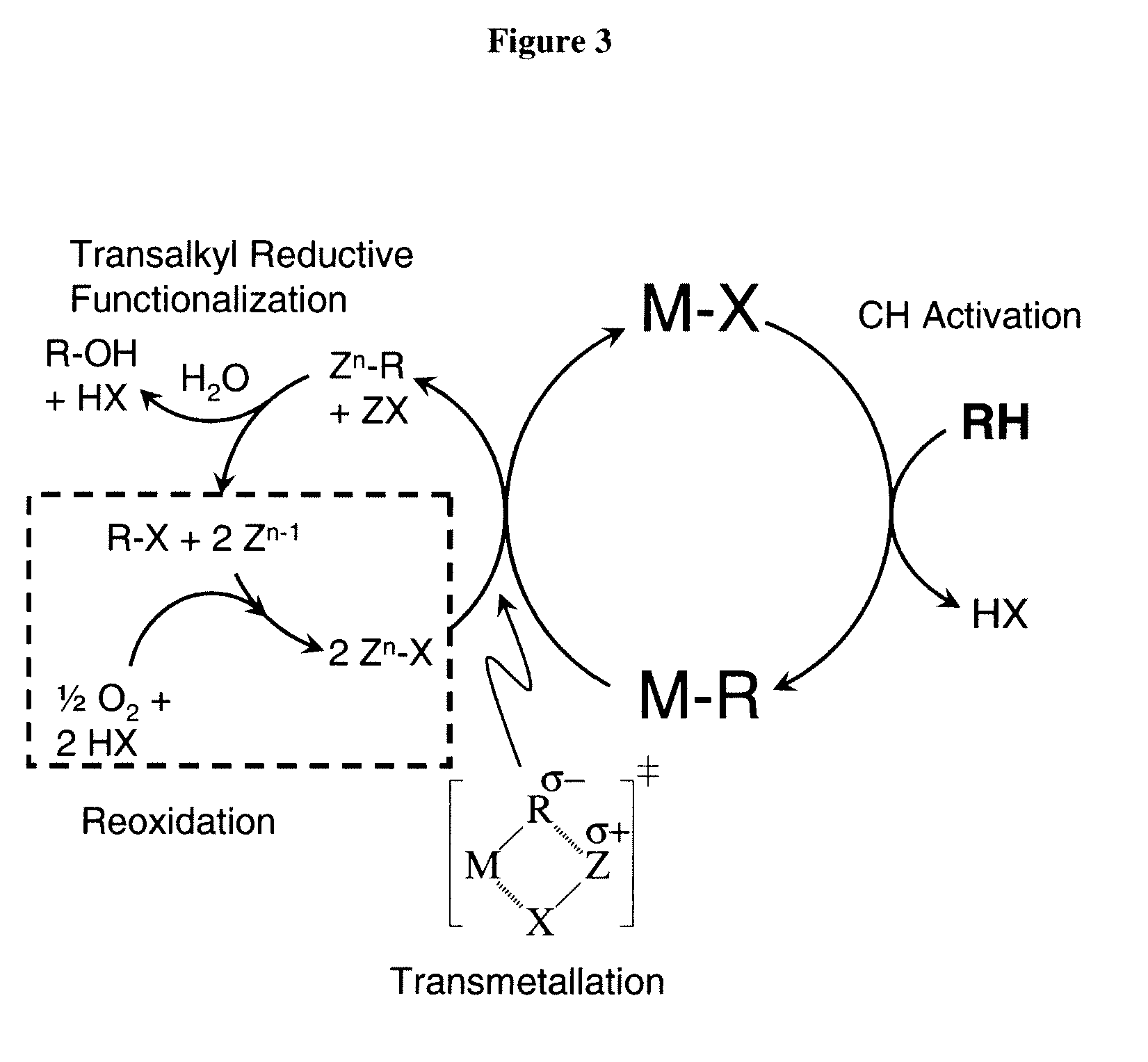

Catalytic oxy-functionalization of metal-carbon bonds

InactiveUS20090264688A1Promote conversionPreparation by oxidation reactionsOrganic compound preparationPtru catalystAlkoxy group

The development of compatible functionalization reactions with methyl rhenium(I) species, for integration with the CH activation reaction of hydrocarbons by transition metal alkoxo complexes is described. The invention is applicable to the design of rapid, stable CH activation systems integrated with an oxy-functionalization reaction for selective, low temperature hydrocarbon oxidation catalysts.

Owner:PERIANA ROY A +2

Constant-pressure alcohol-ether hydrazine production process

InactiveCN101602650AFlexible adjustmentReasonable flowPreparation by oxo-reaction and reductionOxygen compounds by oxo-reactionProduction lineState of art

The invention provides a constant-pressure alcohol-ether hydrazine production process with a competitive replacement choice, which solves the disadvantages of an alcohol-combining process in the prior art. The total pressure of a system in the invention is under low water-coal-slurry gasification pressure between 3.5 and 8 MPa, and no feed-gas compressor is needed. Two chemical engineering processes, namely alcohol-ether synthesis and ammonia synthesis, are serially connected into a production line, wherein alcohol-ether synthesis is performed first, and then ammonia synthesis is performed, but alcohol-ether synthesis and ammonia synthesis are relatively independent of the separation of respective products thereof. The yield proportion of CO / H2 products needed by different reaction is flexible to regulate. The process does not need to provide additional power for feed gas, and can flexibly and reasonably regulate feed gas components of each synthesis procedure in the system, thereby improving the efficiency of the whole process and reducing production cost to the utmost extent.

Owner:FUZHOU UNIV +1

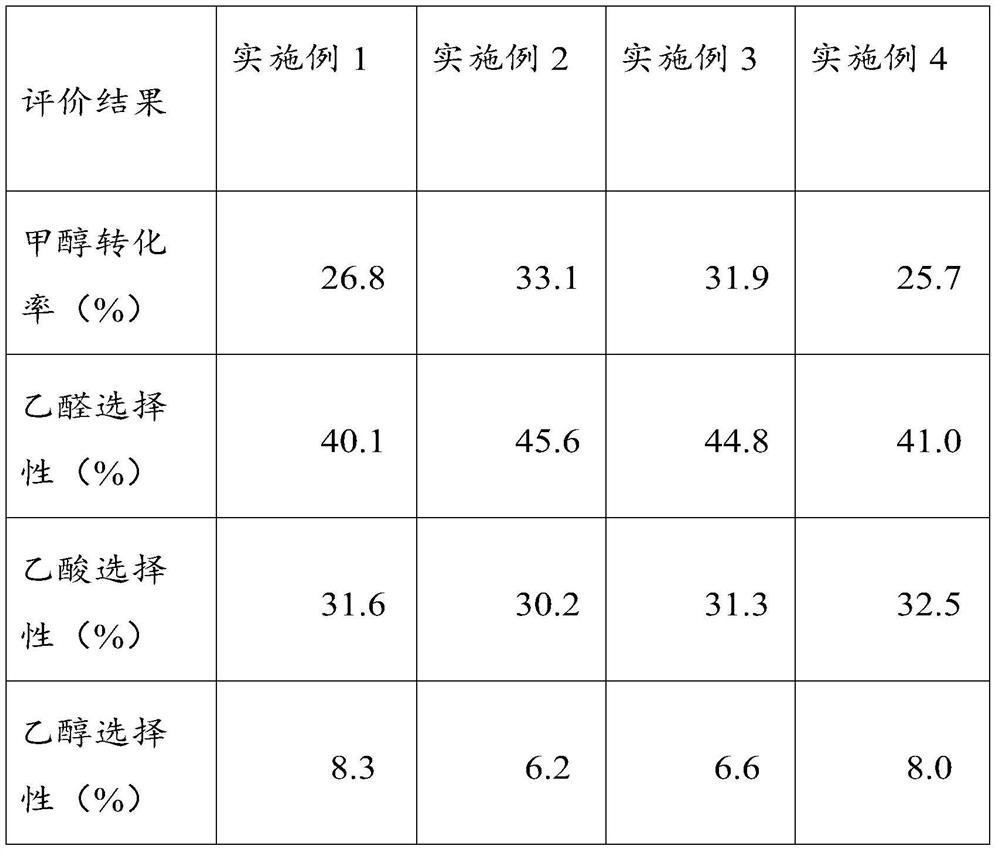

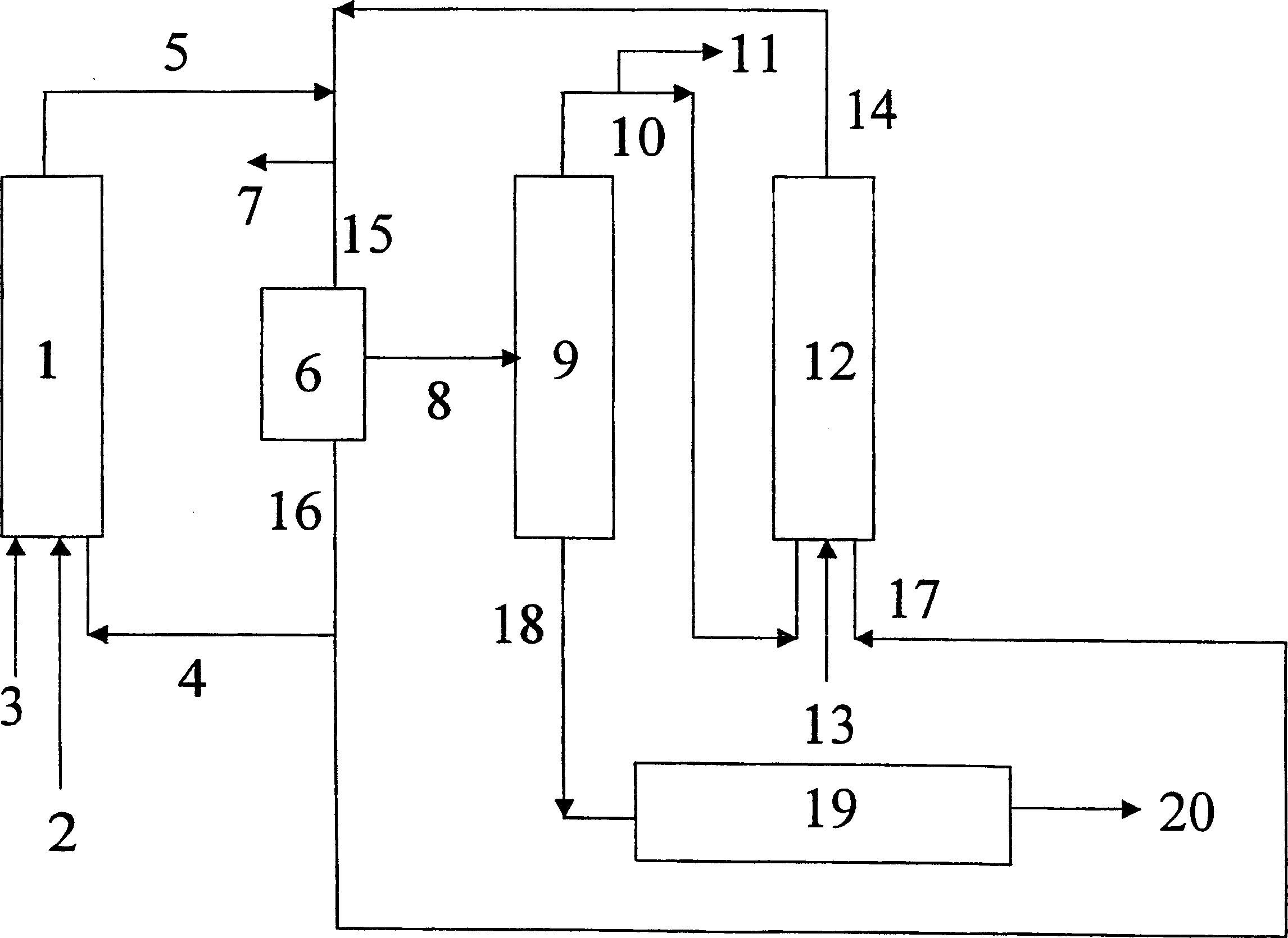

Catalyst for catalyzing methanol carbonylation, preparation method of catalyst and method for preparing acetic acid and methyl acetate by methanol carbonylation

ActiveCN107952439AImprove conversion rateHigh yieldCatalyst activation/preparationPreparation by carbon monoxide or formate reactionAlkaneHydrogen

The invention provides a catalyst for catalyzing methanol carbonylation, a preparation method of the catalyst and a method for preparing acetic acid and methyl acetate by methanol carbonylation. The preparation method of the catalyst comprises the following steps: impregnating a carrier in a metal salt solution of nickel, then drying, roasting and reducing mixed gases of alkane and hydrogen at thetemperature of 300 to 1000 DEG C, wherein the nickel accounts for 1 to 20 percent of the mass of the carrier. The preparation method has the advantages of simple preparation process, low energy consumption and capability of realizing scale production; the catalyst prepared by the method can efficiently catalyze the methanol carbonylation to obtain the acetic acid and the methyl acetate; meanwhile, the catalyst has the advantages of high conversion rate for methanol, excellent catalytic activity, better stability and longer service life. When the catalyst is applied to the method for preparingthe acetic acid and the methyl acetate by the methanol carbonylation, the conditions required by a catalytic reaction are relatively mild and the preparation efficiency is effectively improved at thesame time.

Owner:SHANDONG YUHUANG CHEM CO LTD

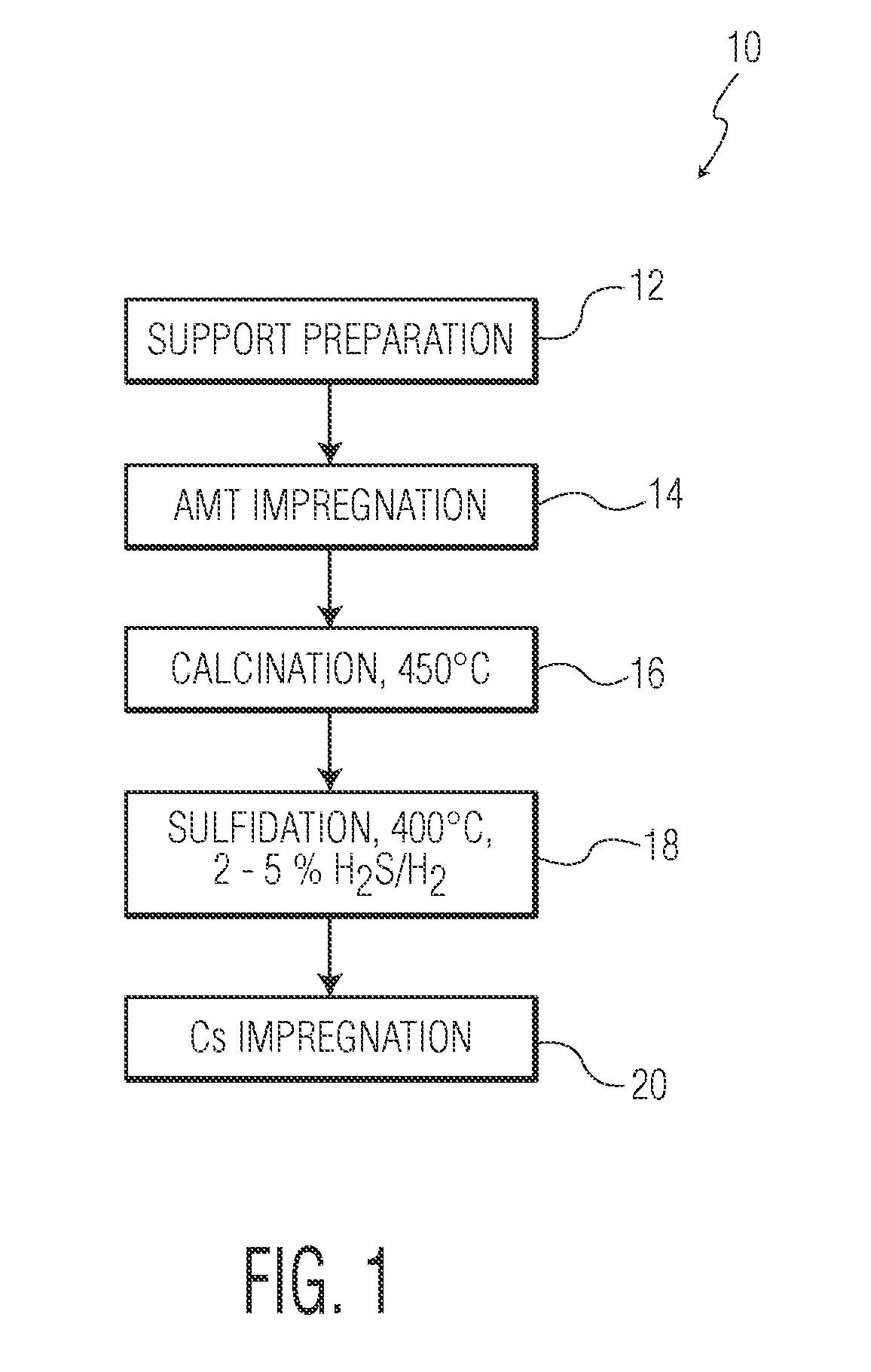

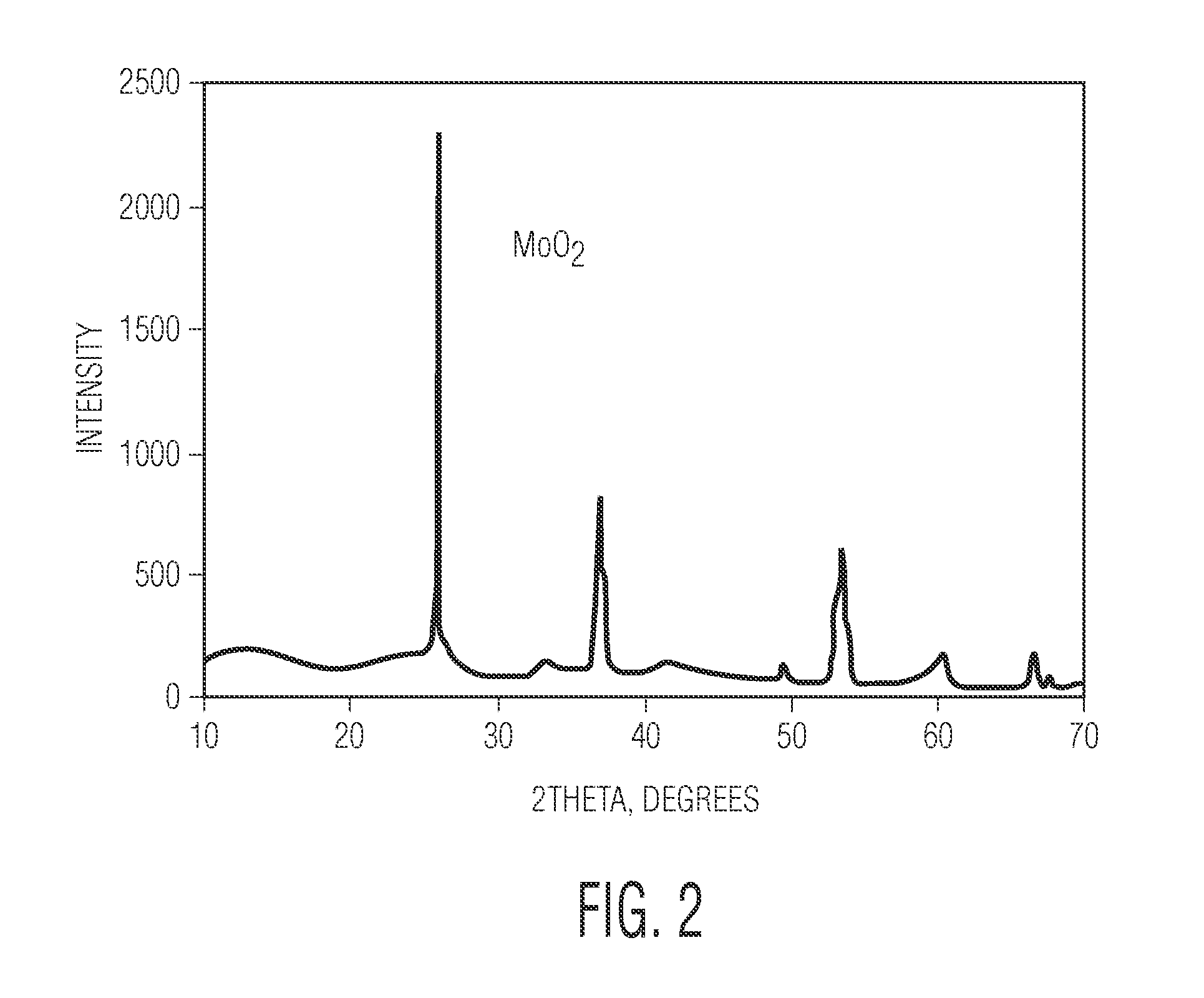

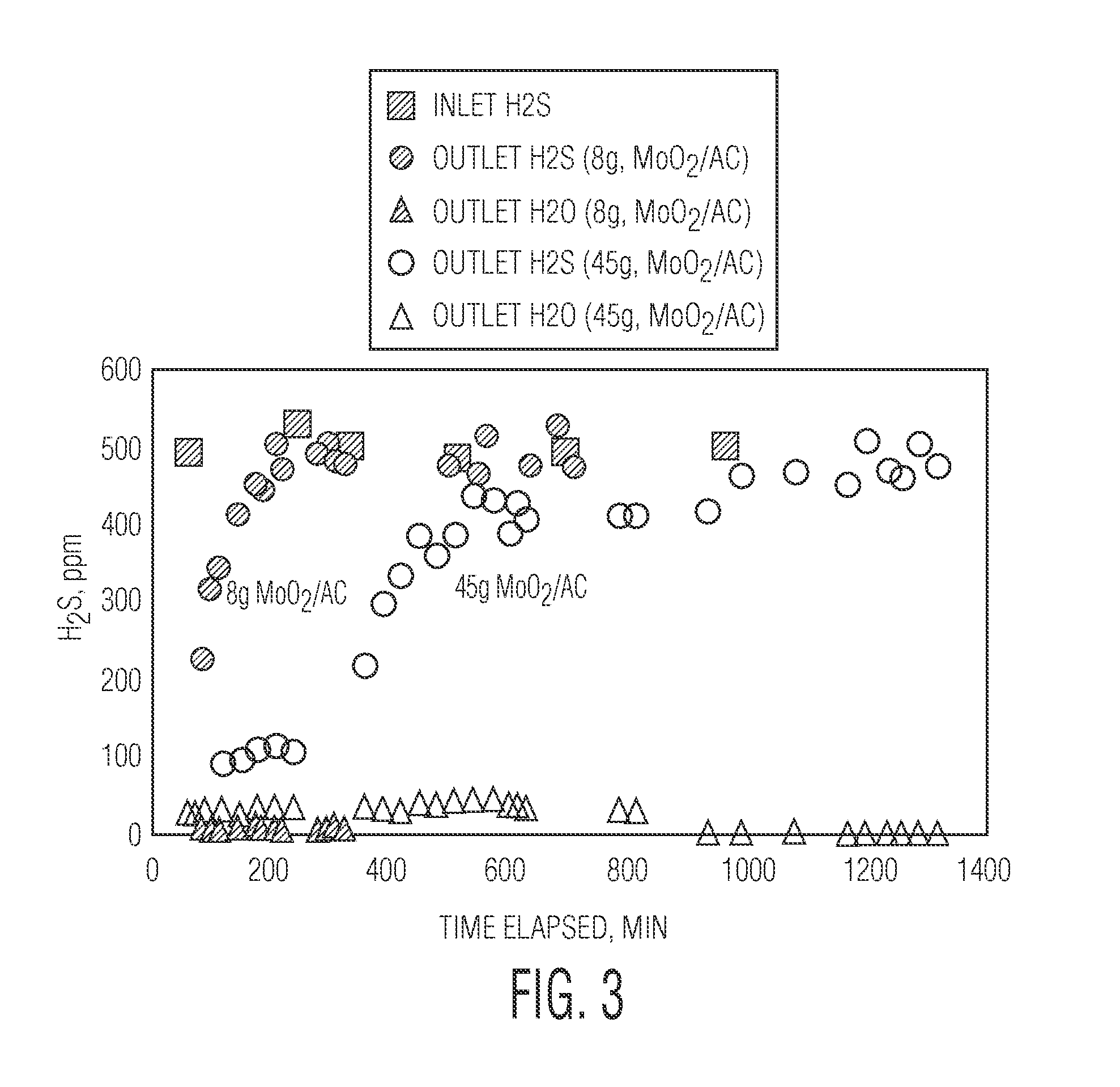

Catalyst composition formulated for synthesis of alcohols and method of preparing the same

InactiveUS8815963B1Low production costQuality improvementOrganic compound preparationOxygen compounds preparation by reductionAlcoholSulfur containing

A catalyst composition includes an active material having a molybdenum- and sulfur-containing substance impregnated with an effective amount of cesium sufficient to promote synthesis of an alcohol, optionally carried on an inert support, wherein the active material is at least substantially free of a transition metal. The present invention is further directed to methods of preparing and using the same.

Owner:AUXILIUM GREEN +1

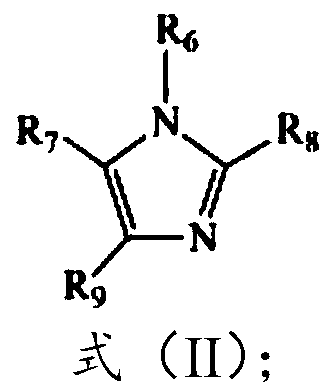

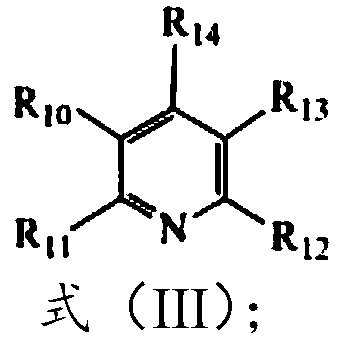

An amphoteric crosslinked polymer catalyst loaded with a noble metal, a preparing method thereof and an alcohol oxidation method

ActiveCN107537565AHigh catalytic efficiencyGood size controlOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationOxygen

An amphoteric crosslinked polymer catalyst loaded with noble metal nanoparticles is disclosed. The catalyst is a composition obtained by subjecting an amphoteric crosslinked polymer and a methanol solution of a noble metal salt to a coordination reaction and then performing reduction utilizing sodium borohydride. The amphoteric crosslinked polymer is a crosslinked copolymer of divinyl benzene, a vinyl heterocyclic type monomer and an acrylic acid type monomer. The catalytic efficiency of the catalyst is high. Any oxidant except oxygen, an inorganic alkali, and other reaction auxiliary agents are not needed. The reaction conversion ratio and selectivity are adjustable. After the reaction is finished, the catalyst can be separated through centrifugation or filtration and reutilized, and therefore the catalyst is environmentally friendly and meets requirements on sustainable development.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Amphoteric cross-linked polymer supported noble metal catalyst and preparation and alcohol oxidation method

ActiveCN107537565BSignificant progressGood size controlOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMaterials science

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heterogeneous catalytic method and device for olefin hydroformylation to synthesize aldehydes and alcohols

ActiveCN104591960BEasy to separateLess investmentPhysical/chemical process catalystsOrganic compound preparationSyngasAlcohol

The present invention relates to a heterogeneous catalysis process for synthesizing aldehydes and alcohols through olefin hydroformylation, and an apparatus thereof. More particularly, the present invention provides a heterogeneous catalysis method for synthesizing aldehydes and alcohols through olefin hydroformylation, wherein the method comprises that olefin and synthesis gas are continuously fed into a reactor to be in a hydroformylation reaction in the presence of a loaded heterogeneous catalyst, and the generated products such as aldehydes and alcohols continuously flow out from the reactor so as to achieve the separation from the catalyst and the continuous production. The present invention further provides the apparatus for the method, wherein the apparatus comprises the reactor, a pre-heater arranged on the upstream of the reactor and connected with the reactor, a mixer arranged on the upstream of the pre-heater and connected with the pre-heater, and a collecting tank arranged on downstream of the reactor and connected with the reactor. The process and the apparatus of the present invention have advantages of excellent hydroformylation performance, easy product and catalyst separation, and simple process, and further have industrial prospects.

Owner:中科榆林能源技术运营有限责任公司

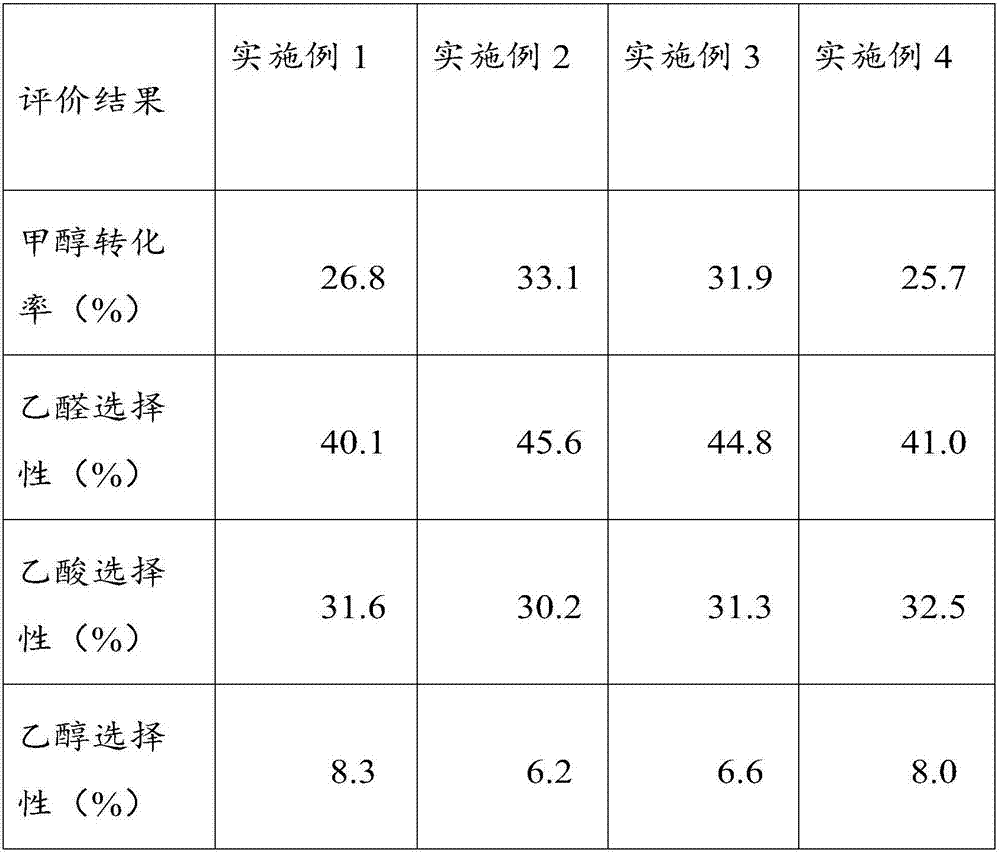

Catalyst for preparing acetaldehyde from methanol synthesis gas and preparation method thereof

ActiveCN107952434BIncreased carbonylationThe carbonylation reaction increasesCatalyst activation/preparationPreparation by carbon monoxide reactionParacetaldehydePtru catalyst

The invention relates to a catalyst for preparing acetaldehyde from methanol synthesis gas and a preparation method thereof, and relates to the field of chemical catalyst preparation. Wherein, the catalyst includes a carrier, an active component and an auxiliary; the active component includes at least one of Pd, Zn, Co, Ni, Mn, Cu and Fe, and the auxiliary is an alkali metal. The preparation method of the catalyst comprises: immersing the solution of the precursor dissolved with the active component and the precursor dissolved with the auxiliary agent on the carrier, drying, and roasting under nitrogen or inert gas atmosphere, the preparation process is simple, and it is convenient for industrial production. The prepared catalyst for preparing acetaldehyde from methanol synthesis gas has better catalytic activity and high selectivity to acetaldehyde, and can be used in industrialized preparation of acetaldehyde.

Owner:SHANDONG YUHUANG CHEM CO LTD

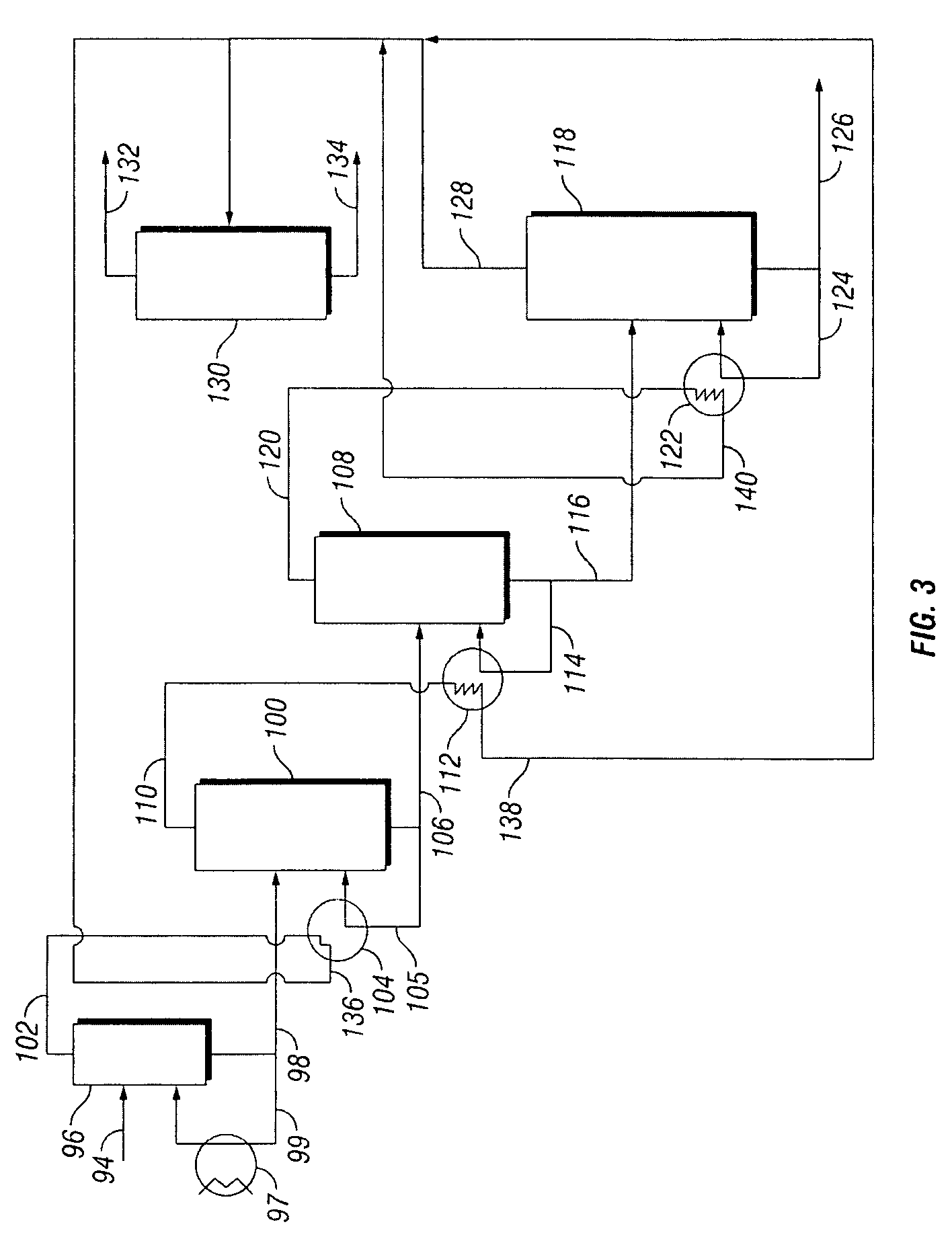

Multi-stage preparation process of carbonyl synthesizing aldehyde and/or alcohol

InactiveCN1230406CImprove conversion rateHigh selectivityPreparation by oxo-reaction and reductionOrganic compound preparationAlcoholBoiling point

Owner:EVONIK DEGUSSA GMBH

Catalyst for preparing acetaldehyde from methanol synthetic gas and preparation method of catalyst

ActiveCN107952434AIncreased carbonylationThe carbonylation reaction increasesCatalyst activation/preparationPreparation by carbon monoxide reactionSyngasActive component

The invention relates to a catalyst for preparing acetaldehyde from methanol synthetic gas and a preparation method of the catalyst, which relates to the field of the preparation of chemical catalysts. The catalyst comprises a carrier, an active component and additive; and the active component is prepared from at least one of Pd, Zn, Co, Ni, Mn, Cu and Fe, and the additive is alkali metal. The preparation method of the catalyst comprises the following steps: soaking a carrier in a solution dissolved with a precursor of the active component and a precursor of the additive, drying, and roastingin a nitrogen or an inertial gas atmosphere. By adopting the catalyst, the preparation process is simple, and the industrialized production is facilitated. The prepared catalyst for preparing the acetaldehyde from methanol synthetic gas has relatively good catalytic activity, is high in selectivity for acetaldehyde, and applicable to the industrialized preparation of the acetaldehyde.

Owner:SHANDONG YUHUANG CHEM CO LTD

Fowls egg protein and method for catalytic oxidation of alcohol by solid supported metalloporphyrin thereof

InactiveCN101406849BEasy to prepareLow priceOrganic-compounds/hydrides/coordination-complexes catalystsOxygen compounds by oxo-reactionEgg proteinCatalytic oxidation

The invention provides a method for catalyzing and oxidizing ethanol through poultry egg protein and solid-supported metalloporphyrin thereof. The method comprises the following steps: a poultry egg protein colloidal solution is stirred to be uniform in system and then dried, so as to obtain a poultry egg protein catalyst; a benzene solution dissolved with metalloporphyrin is dripped to the poultry egg protein colloidal solution, is stirred to be uniform in system and then dried to obtain a poultry egg protein metalloporphyrin catalyst; the prepared catalyst and ethanol are put into a high-pressure reaction kettle according to the mass ratio of between 2.9 and 0.3 to 158, and are introduced with air with the airflow rate of 0.04m<3> / h so as to react for 2 to 4.0 hours at the stirring rateof between 200 and 600 r / min, at a temperature of between 130 and 150 DEG C, under the pressure of between 0.8 and 1.2 MPa; and then the ethanol is catalyzed and oxidized so as to generate acetaldehyde and acetic acid. The catalyst prepared by use of the method contains no toxic heavy metal and causes no waste fluid polluting environment.

Owner:GUANGXI UNIV

Method for prodn. of phenol and acetone by acid-catalysed cleavage of cumen hydroperoxide

InactiveCN1156420CHigh selectivityPhysical/chemical process catalystsOrganic compound preparationAcid catalyzedPhenol

In the production of phenol and acetone by acid-catalyzed homogeneous cracking of cumene hydroperoxide (CHP) in reactor(s) with tube flow characteristics, in which part of the cracked stream is recycled and combined with the CHP feed stream, the weight ratio of recycled cracked stream to CHP stream (recycling ratio) is less than 10.

Owner:石碳酸化学股份有限公司

Popular searches

Anionic surface-active compounds Non-surface-active detergent compositions Hydrocarbons from unsaturated hydrocarbon addition Hydrocarbons Preparation by carbon oxide reduction Liquid soaps Biofuels Chemical recycling Carboxylic preparation from carbon monoxide reaction Carbonyl compound separation/purification

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com