Catalyst for preparing acetaldehyde from methanol synthetic gas and preparation method of catalyst

A technology of methanol synthesis gas and catalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, carbon monoxide reaction preparation, etc. It can solve the problem of low ethane conversion rate and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

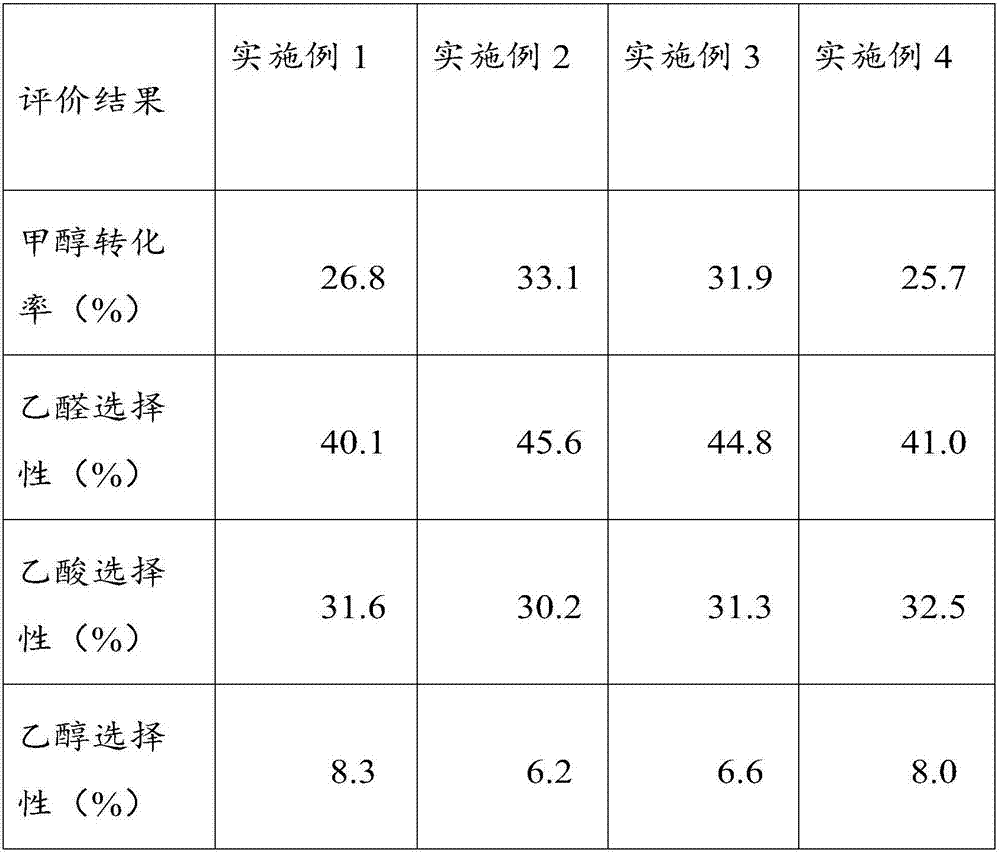

Examples

preparation example Construction

[0021] The preparation method of catalyst comprises:

[0022] S1. Immerse the solution of the precursor dissolved with the active component and the precursor dissolved with the auxiliary agent on the carrier.

[0023] Among them, the precursor of the active component is an organic water-soluble salt solution or an inorganic water-soluble salt solution of metals Pd, Zn, Co, Ni, Mn, Cu, and Fe. Specifically, the organic water-soluble salt includes acetate, and the inorganic water-soluble Salts include any of sulfates, nitrates and chlorides.

[0024] The precursor of the auxiliary agent is an inorganic water-soluble metal salt of alkali metal Na, K, Li and Cs, wherein the inorganic water-soluble metal salt includes any one of carbonate, nitrate, chloride and sulfate.

[0025] The solution of the precursor dissolved with the active component and the precursor dissolved with the auxiliary agent can be configured in the following way:

[0026] The precursor of the active componen...

Embodiment 1

[0036] A catalyst for preparing acetaldehyde from methanol synthesis gas, which is prepared by the following method:

[0037] Weigh 1.30g of palladium nitrate dihydrate and dissolve in distilled water to obtain 8ml of palladium nitrate solution; then weigh 0.11g of potassium nitrate and dissolve in distilled water to obtain 3ml of potassium nitrate solution, mix the above palladium nitrate solution and the above potassium nitrate solution at room temperature Mix evenly under ultrasonic to obtain a mixture.

[0038] Add the above mixed solution to 10g of SiO with a particle size of 20-40 mesh 2 Above, equal-volume ultrasonic impregnation for 1 hour, followed by static impregnation for 48 hours; then dried overnight in an oven, placed in a tube furnace, and roasted at 300°C for 4 hours in a nitrogen atmosphere to obtain the product.

[0039] Wherein, in the catalyst, the total load of palladium and potassium is 6%.

Embodiment 2

[0041] A catalyst for preparing acetaldehyde from methanol synthesis gas, which is prepared by the following method:

[0042] Weigh 1.83g of copper nitrate trihydrate, 2.25g of zinc nitrate hexahydrate and 0.94g of cobalt acetate tetrahydrate and dissolve in distilled water to obtain 9ml of the first solution, then weigh 0.13g of sodium sulfate and dissolve in distilled water to obtain 5ml of the first solution For the second solution, the first solution and the second solution are ultrasonically mixed at room temperature to obtain a mixed solution.

[0043] Add the above mixed solution to 10 g of activated carbon with a particle size of 20-40 mesh, impregnate with equal volume ultrasonically for 4 hours, and then stand for 32 hours; then dry it overnight in an oven, put it into a tube furnace, and place it in a nitrogen atmosphere Roasting at 650°C for 4h, that is.

[0044] Wherein, in the catalyst, the total load of sodium, copper, zinc and cobalt is 12.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com