Heterogeneous catalytic method and device for olefin hydroformylation to synthesize aldehydes and alcohols

A technology for the synthesis of aldehydes by olefin hydroformylation and heterogeneous catalysis, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., and can solve the problems of low activity and selectivity, low activity and Low selectivity, difficult separation of catalysts and products, etc., to achieve novel and unique technical routes, overcome low activity and selectivity, and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

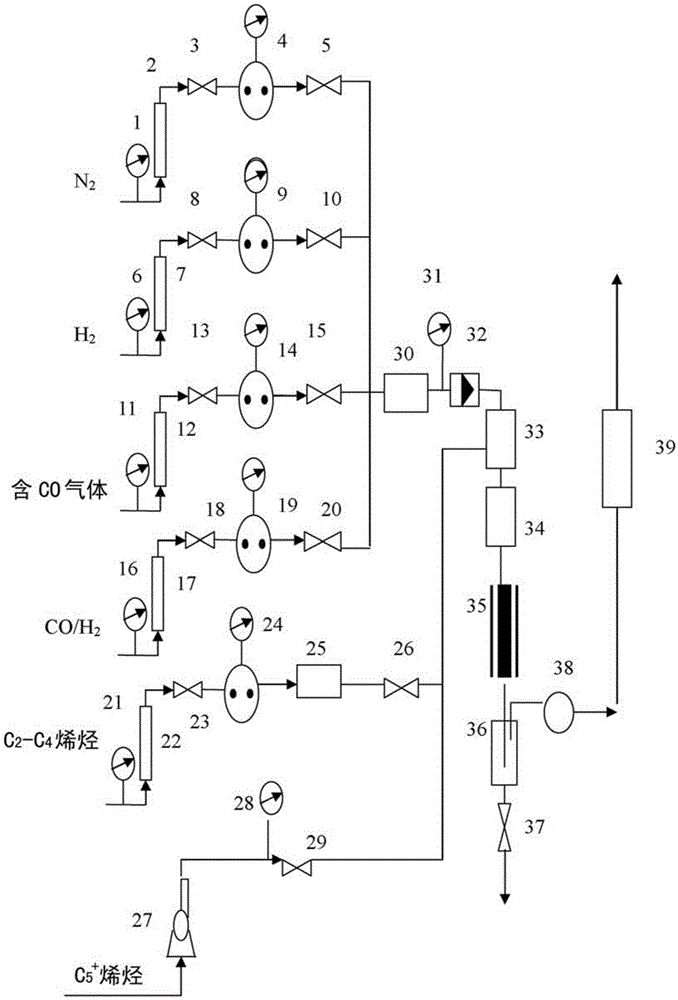

[0102] use figure 1 In the reaction apparatus shown, the reaction was carried out under the following reaction conditions.

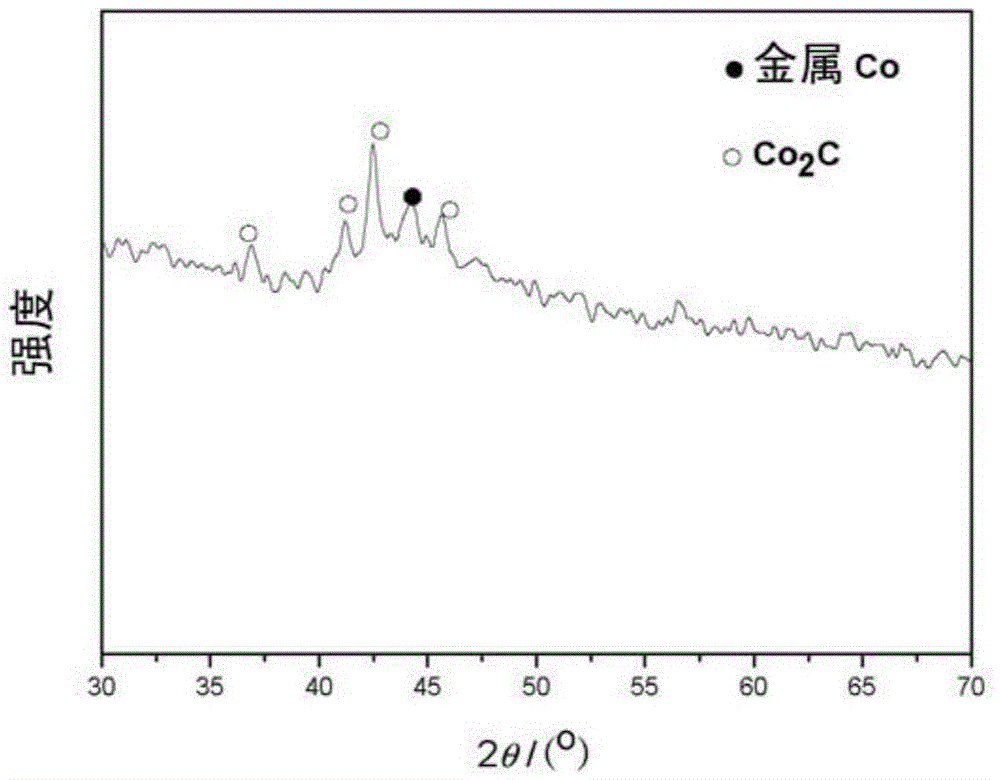

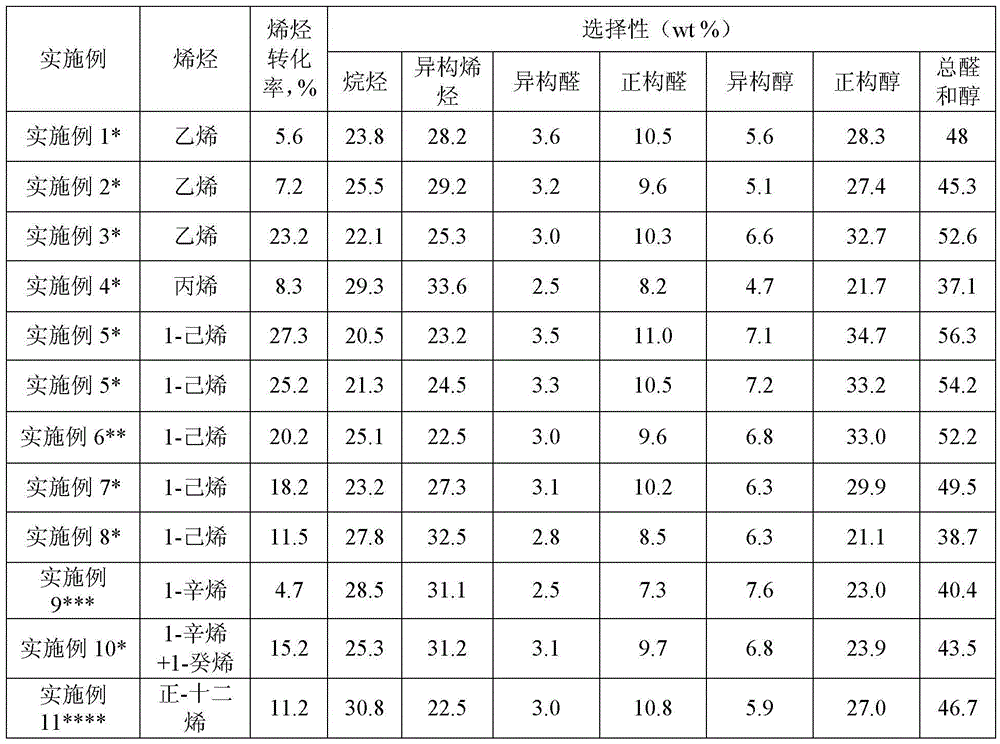

[0103] The production method uses 15Co 2 C(68)Co(32)0.3La / AC1(Co 2 CCo to Co 2 Compounds of C and metal Co, 68 and 32 are represented as Co 2 C The percentage of the peak height of the main diffraction peak and the metal Co diffraction peak height, AC1 is a coconut shell activated carbon) catalyst, and ethylene and synthesis gas are used as raw materials for hydroformylation. The particle size of the catalyst is 0.3-0.5 mm (the particle size of the catalyst is the same as that of the catalyst inorganic salt precursor), and the reactor adopts a fixed-bed reactor. Before the reaction, the 4ml catalyst inorganic salt precursor in the above-mentioned catalyst preparation example was loaded into the fixed-bed reactor, and N 2 Gas atmosphere drying, roasting, reduction and activation of hydrogen-containing mixed gas, and carbonization of CO-containing gas...

Embodiment 2

[0108] use figure 1 The reaction device shown uses 15Co 2 C(68)Co(32)0.3La / AC1 catalyst is used for hydroformylation reaction with ethylene and synthesis gas as raw materials. The particle size of the catalyst is 0.3-0.5 mm, and 4 mL of the catalyst inorganic salt precursor is loaded into a fixed-bed reactor for the hydroformylation reaction.

[0109] Reaction process is the same as embodiment 1, and wherein reaction temperature is 463K, and pressure is 1.0MPa, 50%CO / 50%H 2 The mixed air velocity is 1000h -1 , ethylene space velocity is 500h -1 . After the reaction was stabilized for 6 hours, the product was analyzed for 12 hours to analyze the composition, and the conversion rate of the hydroformylation reaction and the selectivity of aldehydes and alcohols were calculated. The results are listed in Table 1.

Embodiment 3

[0111] use figure 1 The reaction device shown uses 15Co 2 C(68)Co(32)0.3La / AC1 catalyst is used for hydroformylation reaction with ethylene and synthesis gas as raw materials. The particle size of the catalyst is 2-3 mm, and 4 mL of the catalyst inorganic salt precursor is loaded into a fixed-bed reactor for the hydroformylation reaction.

[0112] Reaction process is the same as embodiment 1, and wherein reaction temperature is 453K, and pressure is 2.0MPa, 50%CO / 50%H 2 The mixed air velocity is 1000h -1 , ethylene space velocity is 300h -1 . After the reaction was stabilized for 6 hours, the product was analyzed for 12 hours to analyze the composition, and the conversion rate of the hydroformylation reaction and the selectivity of aldehydes and alcohols were calculated. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com