Aluminium base slurried catalyst and preparation thereof

A catalyst and paste-like technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large AIP investment, low relative Al content, increased organic Solvent amount and other issues, to achieve the effect of reducing raw material cost, low price, and water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

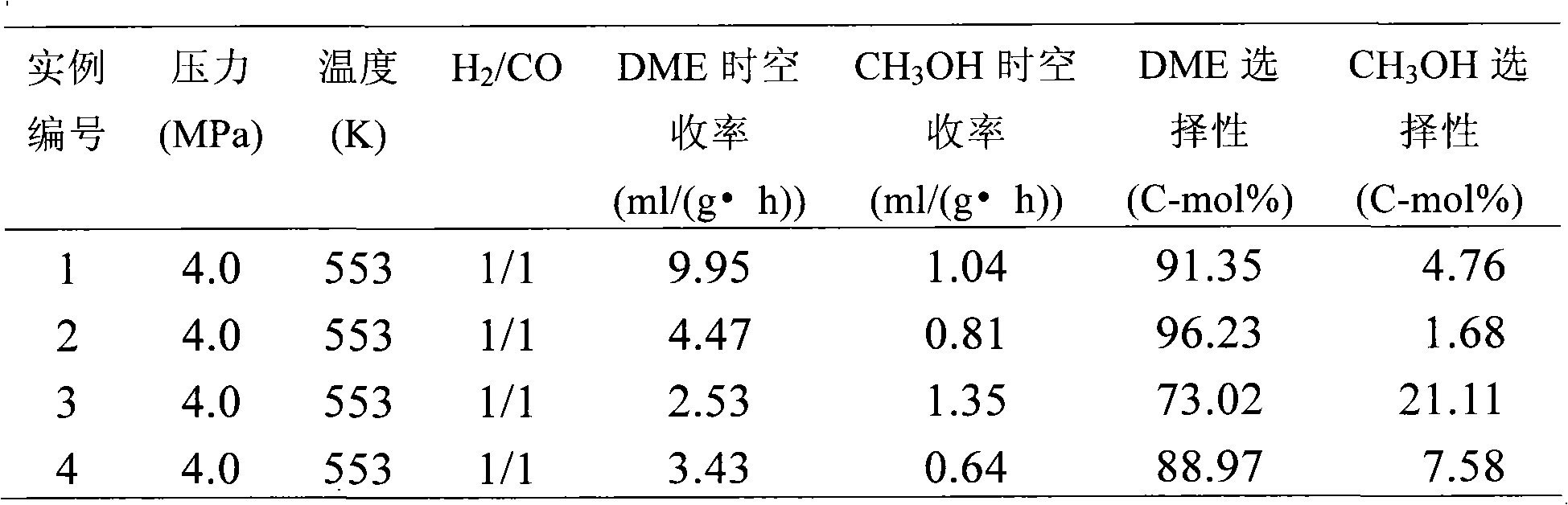

[0018] Specific embodiments 1. Put 9.88g of pseudo-boehmite and 197.6ml of deionized water into a colloid mill to grind and disperse to form an AlOOH slurry, stir and heat at 338K for 0.5h, then add nitric acid to adjust the pH value of the slurry to 0.5, Continue to stir for 0.5 h to obtain AlOOH sol; add 9.95 g of copper nitrate and 12.24 g of zinc nitrate aqueous solutions together to the above AlOOH sol, heat and stir until a gel is formed. After aging, the gel was replaced with acetone, then emulsified and dispersed in liquid paraffin, and finally in N 2 Heat treatment at 573K for 5h under atmosphere and strong stirring to obtain slurry catalyst.

[0019] Embodiment 2. Put 9.88g of boehmite and 39.52ml of deionized water into a colloid mill to grind and disperse to form an AlOOH slurry, stir and heat at 353K for 1.0h, then add phosphoric acid to adjust the pH value of the slurry to 5.0, continue Stir for 1.5 h to obtain AlOOH sol; add 1.99 g of copper nitrate in ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com