Method for separating and reclaiming organic matter from high-temperature Fischer-Tropsch synthesis reaction water

A technology of Fischer-Tropsch synthesis, separation and recovery, applied in the field of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

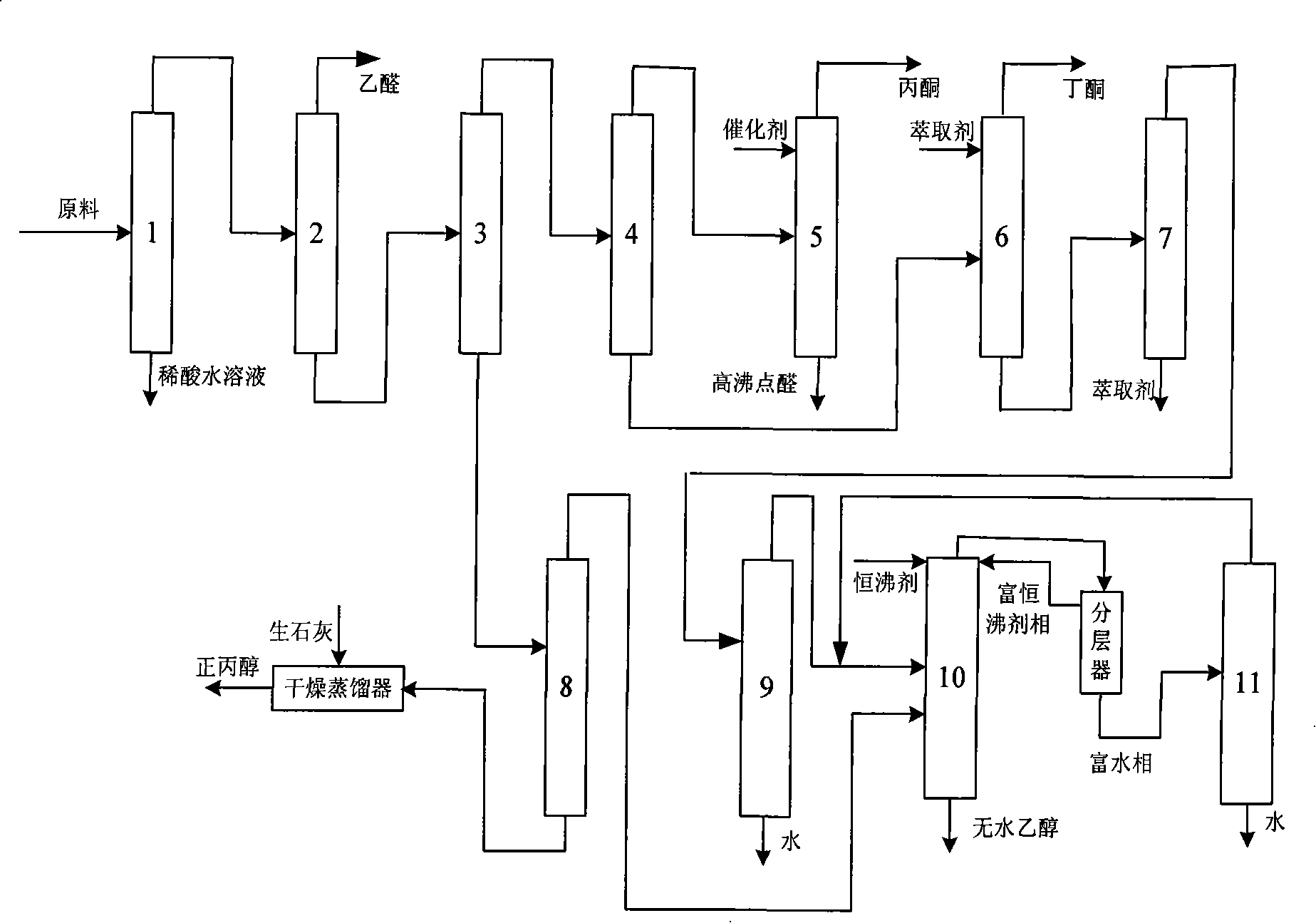

[0071] Such as figure 1 As shown, a method for separating and recovering organic matter in high-temperature Fischer-Tropsch synthesis reaction water, the method comprises using high-temperature Fischer-Tropsch synthesis reaction water as a raw material, and adopting a rectification tower to separate the reaction water raw material, and the top of the rectification tower is all A condenser is provided, and a reboiler is provided in the tower kettle. Rectify under the conditions of temperature, pressure, and reflux ratio that are properly adjusted. If extraction or azeotropic distillation is performed, it is necessary to select an appropriately adjusted amount of extractant or azeotrope and the location of addition to obtain acetone, methyl ethyl ketone, methanol, ethanol, n-propanol product. Described reaction water raw material is composed as follows:

[0072]

[0073] When adjusting the operating conditions of each rectifying tower as follows,

[0074]

[0075] The ...

Embodiment 2

[0078] A method for separating and recovering organic matter in high-temperature Fischer-Tropsch synthesis reaction water, the process of the method is the same as that of Example 1, and the raw material composition of high-temperature reaction water is the same as that of Example 1.

[0079] When adjusting the operating conditions of each rectifying tower as follows,

[0080]

[0081]

[0082] The separation and recovery results are:

[0083] product name

Embodiment 3

[0085] A method for separating and recovering organic matter in high-temperature Fischer-Tropsch synthesis reaction water, the process of the method is the same as in Example 1, and the raw material composition of high-temperature reaction water is as follows:

[0086]

[0087] When adjusting the operating conditions of each rectifying tower as follows,

[0088]

[0089] The separation and recovery results are:

[0090] product name

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com