Method for prodn. of phenol and acetone by acid-catalysed cleavage of cumen hydroperoxide

A technology of cumene hydroperoxide and cumene hydroperoxide, which is applied in the preparation of oxygen-containing compounds, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as the negative impact of selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (comparative example):

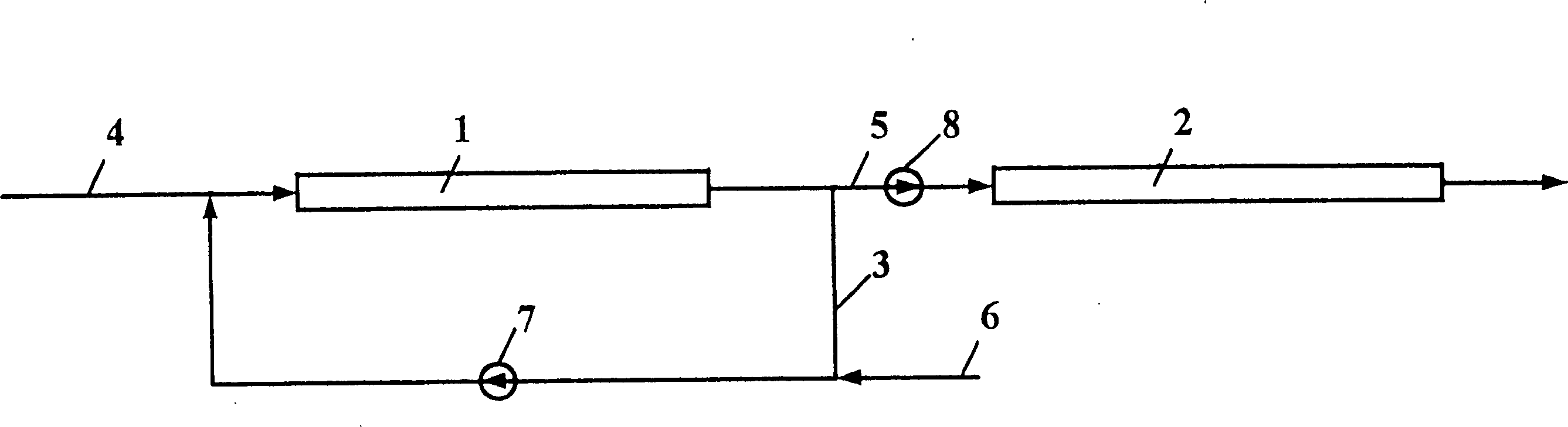

[0028] In a basic structure such as figure 1 In the cracking equipment of the present invention, the CHP content is 67% (weight) technical grade CHP reaction to the residual content in the CHP cracking product is the degree of 1.0% (weight). The cycle ratio λ is set to 17 here. Add an appropriate amount of sulfuric acid as a catalyst to match this.

[0029] Three tube-bundle heat exchangers connected in series ( figure 1 The reactor 1) in is used as a CHP cracking reactor; the reaction temperature is 50°C. The reaction pressure is 1×10 5 Pa (1 bar) (absolute).

[0030] The resulting cleavage product contained 0.21% by weight of high boilers (mainly polymerized AMS and cumylphenol). CHP lysis was followed by DCP lysis.

Embodiment 2

[0031] Embodiment 2 (according to the present invention)

[0032] Except that the circulation ratio is 7, the CHP cracking of Example 1 is carried out under other identical conditions; after adding an appropriate amount of acid, the residual CHP concentration in the CHP cracking product is specified as 0.25% (weight). The cleavage product likewise contained 0.21% by weight of high boilers.

[0033] In this case, by reducing the circulation ratio, although the lower residual CHP concentration has also been achieved, the same selectivity as in Comparative Example 1 can be achieved, but in Example 1, the only way to achieve a lower residual CHP concentration is to increase the acid concentration. The amount of addition, and this will promote the formation of by-products. The size of the cleavage reactor and piping can be correspondingly smaller. In addition, lower residual CHP content is more beneficial to the safety of downstream equipment.

Embodiment 3

[0034] Embodiment 3 (according to the present invention)

[0035] The circulation ratio was set to 7, and then under the same conditions, including the residual CHP concentration in the cleavage product being 1.0% by weight, the CHP cleavage of Example 1 was implemented. The content of high boilers in the cleavage product was 0.16% by weight. Compared with Example 1, the selectivity was significantly increased by reducing the recycle ratio. Compared with Example 2, it is shown that the selectivity can be improved by increasing the residual CHP concentration at low circulation ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com