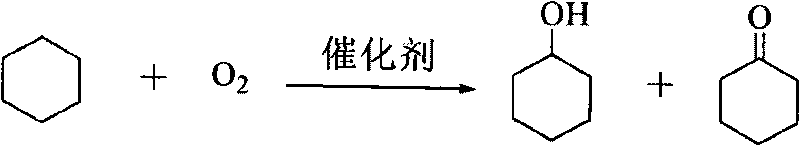

Method for preparing cyclohexanol and cyclohexanone through cyclohexane oxidation

A technology of cyclohexane and cyclohexanol, which is applied in the direction of oxidation reaction preparation, chemical instruments and methods, and carbon-based compound preparation. It can solve the problems of non-reusable use, high catalyst cost, and harsh use conditions, and achieve reusability. Good, simple catalytic system, easy to separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add cyclohexane 4mL, CoFe 2 o 4 5mg, filled with 1.6MPa O 2 , 145 ° C under magnetic stirring reaction 6h. After the reaction is finished, the catalyst and the reaction solution are separated by simple filtration, so that the catalyst can be recycled. After the reaction solution was diluted with absolute ethanol, it was analyzed qualitatively by HP6890 / 5973 mass spectrometer and quantitatively by Agilent 6820 gas chromatograph. The results obtained: the conversion rate of cyclohexane was 16.2%, and the selectivity of cyclohexanol and cyclohexanone was 92.4%.

Embodiment 2

[0018] Except the catalyst is 5mg CuFe 2 o 4 Except, other conditions are with embodiment 1. The results obtained: the conversion rate of cyclohexane was 13.4%, and the selectivity of cyclohexanol and cyclohexanone was 90.2%.

Embodiment 3

[0020] Except the catalyst is 5mg NiFe 2 o 4 Except, other conditions are with embodiment 1. The results obtained: the conversion rate of cyclohexane was 10.6%, and the selectivity of cyclohexanol and cyclohexanone was 90.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com