Pulse tube expansion machine

A technology of expanders and pulse tubes, applied in compressors, refrigerators, compressors, etc., can solve problems such as accompanying losses in the expansion process, achieve high feasibility, improve energy utilization efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

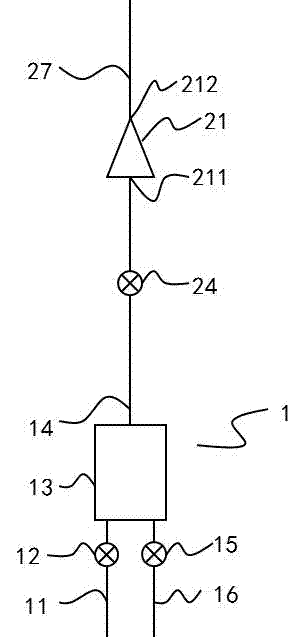

[0025] Such as figure 1 As shown, there is an inflow pipeline 11 and an inflow valve 12 on the pulse tube 13, an outflow pipeline 16 and an outflow valve 15, an outlet pipeline 14 is arranged, and an outlet valve 24 is arranged on the outlet pipeline 14, and the outlet pipeline 14 is connected to the low-pressure end 211 of the compressor 21. Connected, the high-pressure end 212 of the compressor 21 is connected with the expansion gas outflow pipeline 27, the pulse tube 13 is a cavity or empty pipe with a certain volume, and the expansion gas outflow pipeline 27 is an external output port, which can make the expander output the compressed air outward. used steam for other purposes.

[0026] Such as figure 1 As shown, the working process is as follows:

[0027] Liquid inlet process: the outflow valve 15 is closed and the inflow valve 12 is opened. The high-pressure liquid to the vessel 13 through the inflow pipe 11 flows into the lower end of the vessel 13 . When th...

Embodiment 2

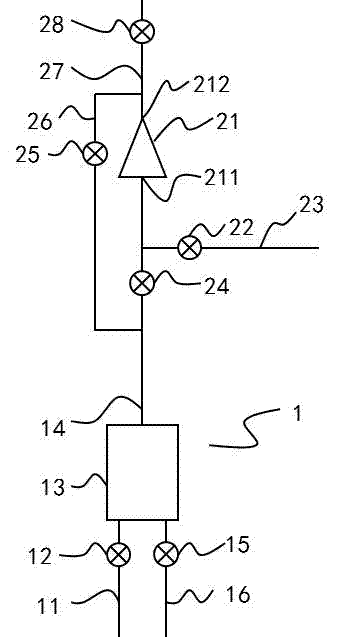

[0041] Such as image 3 As shown, a low-pressure bypass pipe 23 is added to the low-pressure end of the compressor 21, and a low-pressure bypass valve 22 is arranged on it, and a high-pressure bypass pipe 26 connects the high-pressure end and the low-pressure end of the compressor 21, and there is a high-pressure bypass Road valve 25. An inflation gas outflow valve 28 is installed on the inflation gas outflow pipeline 27 . Here, the low-pressure bypass pipe 23 communicates with the outside world, allowing the compressor to suck low-pressure steam.

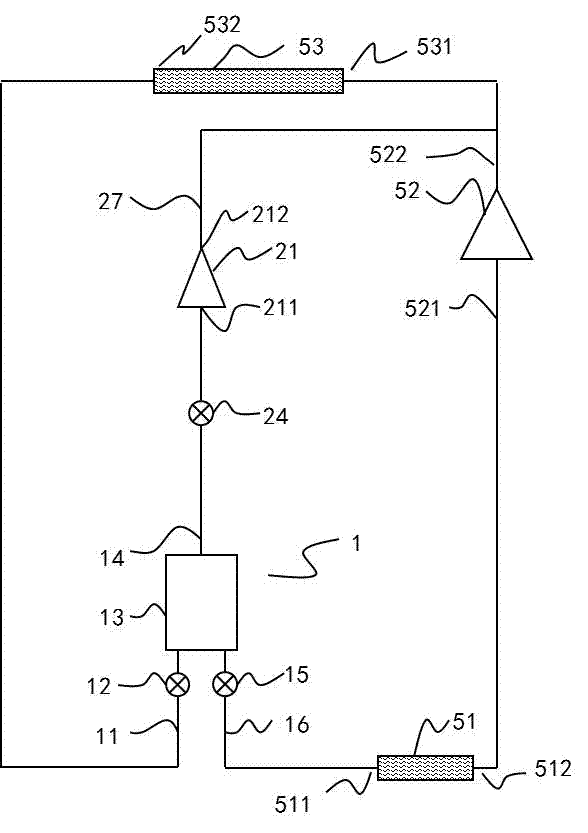

[0042] Such as Figure 4 As shown, the low-pressure bypass pipe 23 is connected to the low-pressure pipe 521 .

[0043] In this embodiment, the compressor 21 is always on. But it can also be stopped when the valve is switched.

[0044] Such as image 3 As shown, the working process of the expander 1 is as follows:

[0045] Liquid inlet process: the low-pressure bypass valve 22 is closed, the high-pressure bypass va...

Embodiment 3

[0064] see Figure 5 , add high-pressure gas discharge pipeline 32 and low-pressure gas inlet pipeline 34 on the top of pulse tube, high-pressure gas discharge valve 31 is arranged on high-pressure gas discharge pipeline 32, low-pressure gas inlet valve 33 is arranged on low-pressure gas inlet pipeline 34. Before the inflow valve 12 , the high-pressure liquid storage tank 55 and the auxiliary condenser 551 are connected through the inflow pipe 11 , and the high-pressure liquid storage tank 55 is connected to the condenser liquid outlet pipe 54 . After the outflow valve 15 is connected to the low-pressure liquid storage tank 56 through the outflow pipe 16, the low-pressure liquid storage tank 56 is connected with an evaporator liquid inlet pipe 59. The low-pressure gas inlet pipe 34 is connected to the top of the low-pressure liquid storage tank 56 , and the high-pressure gas discharge pipe 32 is connected to the top of the high-pressure liquid storage tank 55 .

[0065] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com