cutting machine

A cutting machine and cutting technology, which are applied in the cutting of textile materials, textile and papermaking, metal processing, etc., can solve problems such as difficulty in correction, and achieve the effects of reducing the inflow of air, reducing costs, and preventing the drop of suction pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

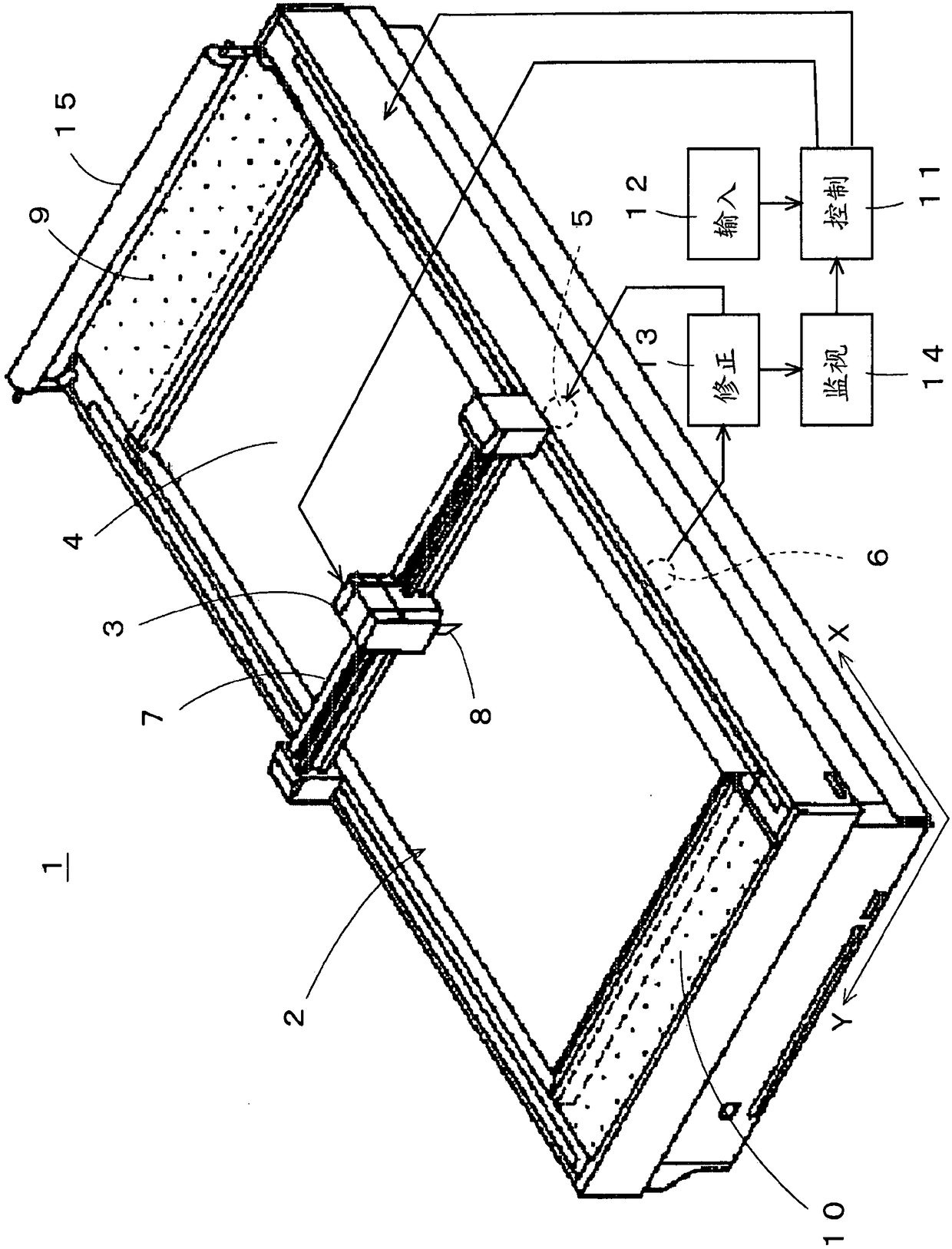

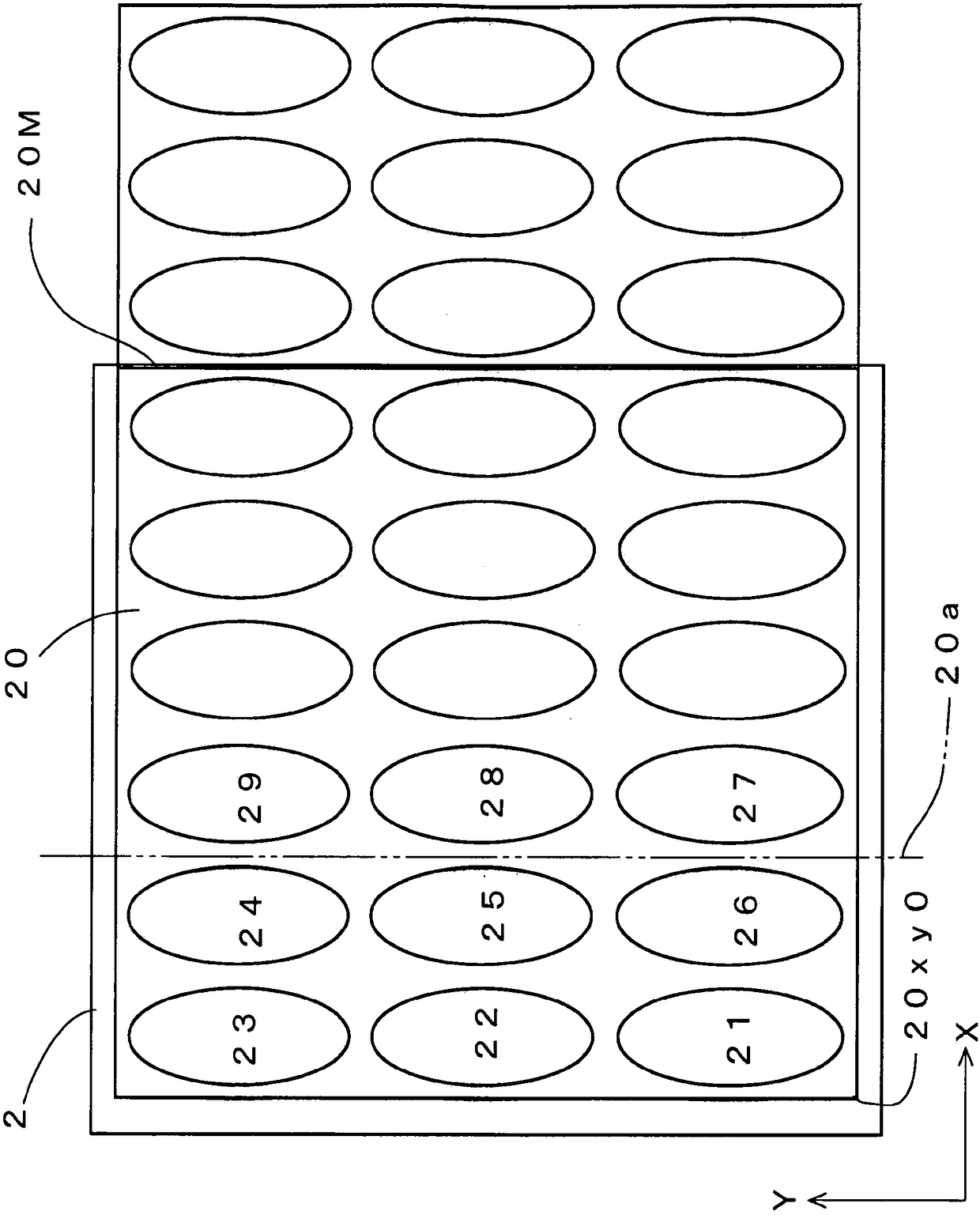

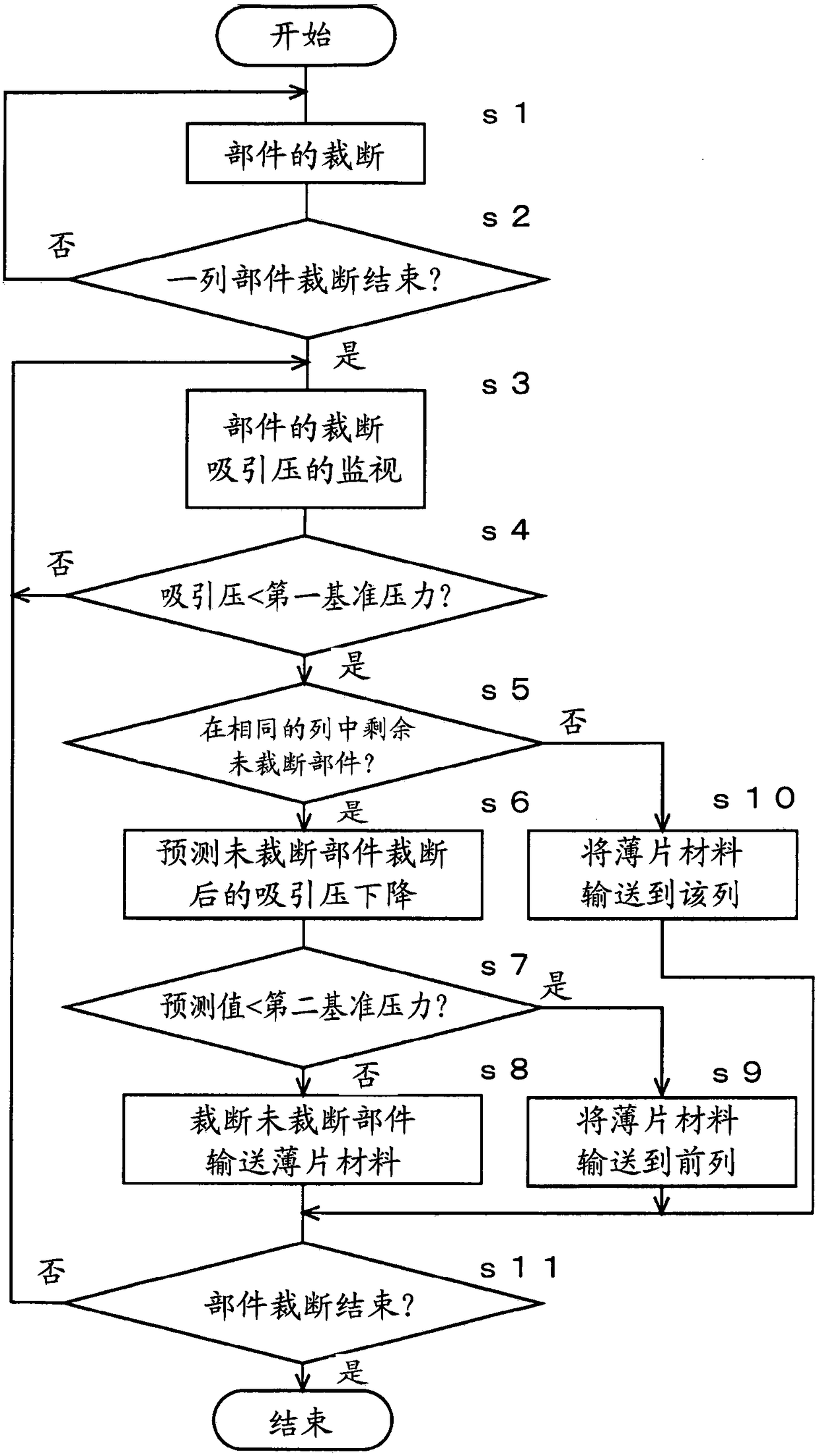

[0032] figure 1The schematic structure of the cutting machine 1 which is one Example of this invention is shown. The cutting machine 1 includes a cutting table 2 and a cutting head 3 . The cutting table 2 has a function of attracting and fixing a sheet material covered with an airtight sheet for cutting a plurality of parts. The cutting head 3 moves along the surface of the cutting table 2 . The surface of the cutting table 2 is formed of an air-permeable bristle brush or felt as a conveyor belt 4, which can convey stacked sheet materials. In the cutting table 2 , a blower 5 is provided below the conveyor belt 4 to suck air and suck the sheet material covered with the airtight sheet toward the surface of the conveyor belt 4 . A sensor 6 is provided below the conveyor belt 4 in order to detect the suction pressure. The Y beam 7 travels along the surface of the conveyor belt 4 in the X-axis direction serving as the conveyance direction, and extends in the Y-axis direction pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com